A method for manufacturing silicon carbide-based ceramic parts based on 3dp additive manufacturing technology

A technology of silicon carbide ceramics and silicon carbide ceramic powder, which is applied in processing and manufacturing, additive processing, etc., can solve the problems of poor mechanical properties, difficulty in manufacturing parts with complex structures, and low density, and achieve good high-temperature comprehensive performance , solve manufacturing difficulties, avoid the effect of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

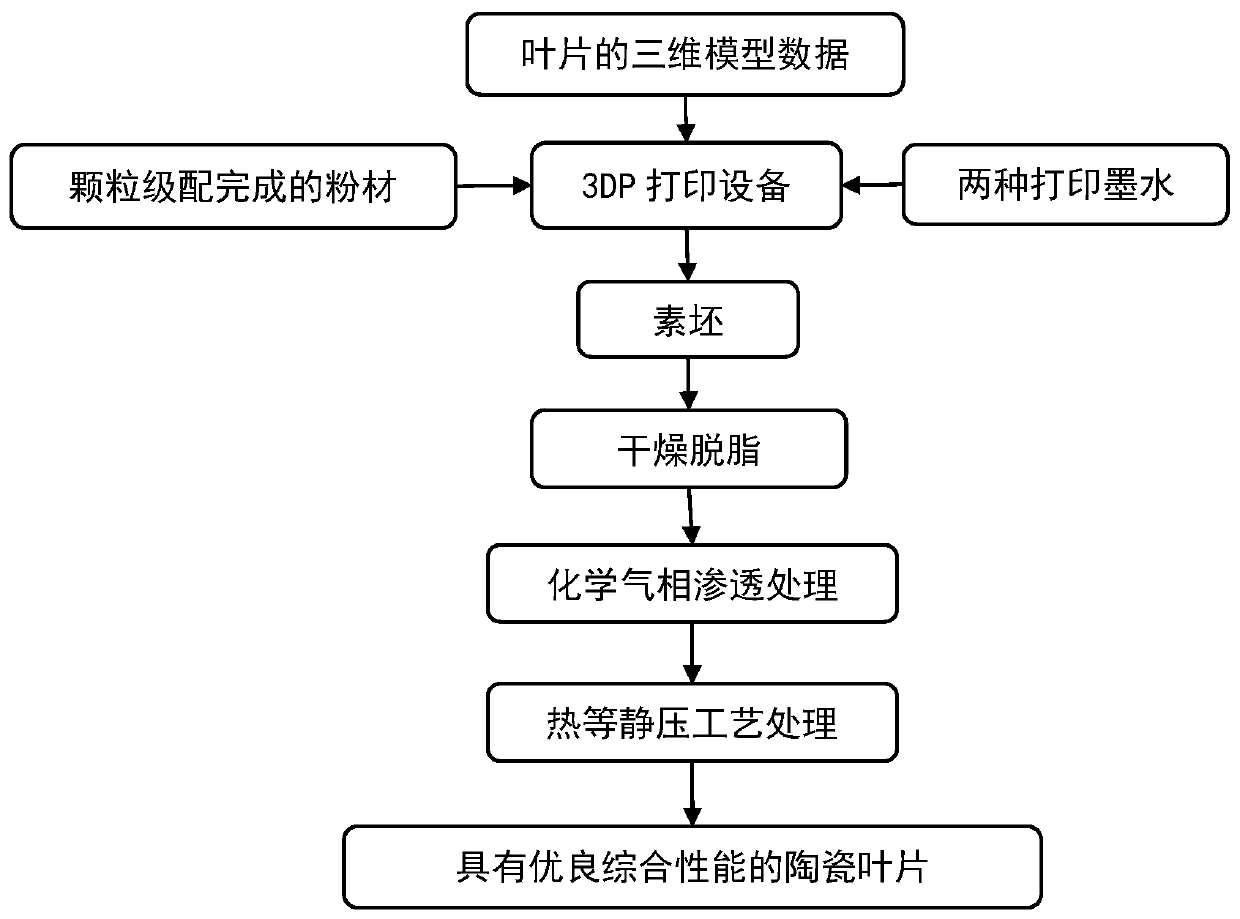

Method used

Image

Examples

Embodiment 1

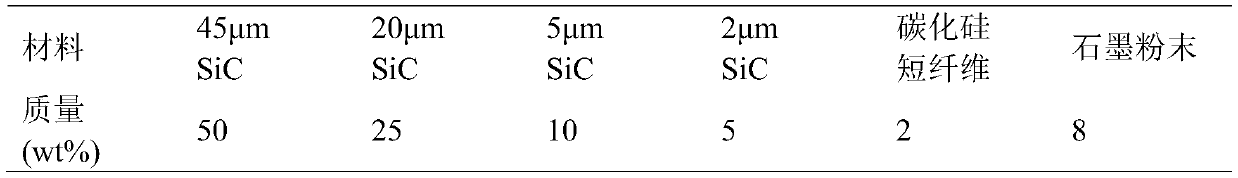

[0031] 1. Preparation of silicon carbide ceramic powder for 3DP printing equipment;

[0032] After mixing silicon carbide powder, silicon carbide short fiber, and graphite powder with a particle size of 45 μm, 20 μm, 5 μm, and 2 μm according to the composition of the ceramic powder ratio Table 1, add about 0.2– 0.5% citric acid to trigger the solidification reaction of the adhesive. After the preparation is completed, ball mill for 30 minutes and fully mixed to become silicon carbide ceramic powder for 3DP printing equipment;

[0033] Table 1 Ceramic powder ratio

[0034]

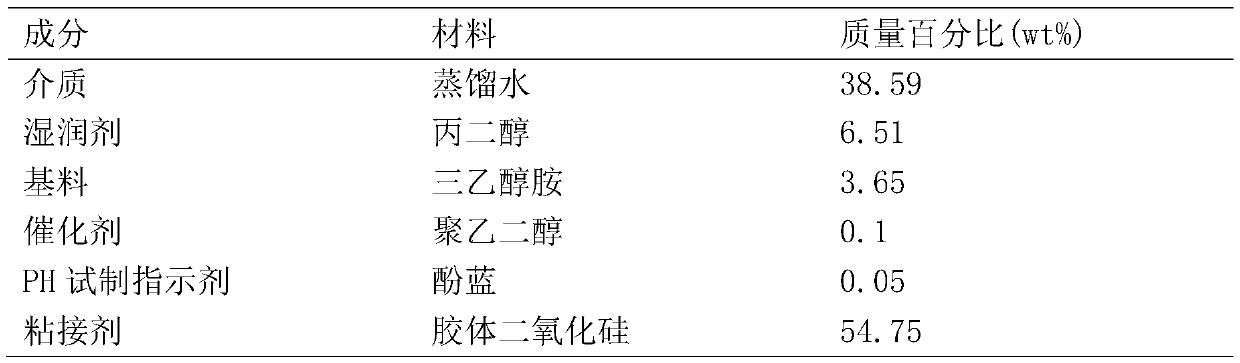

[0035] 2. Equipped with 3DP printing ink with dual curing system;

[0036] The configuration of adhesive 1: colloidal silica (particle size is 5-100nm, the pH value of the base material in the solution should be 9-12, to stabilize the colloidal silica and prevent it from premature solidification, used in stainless steel Nickel nozzle) and triethanolamine (base material) adopt polyethylene glycol as the...

Embodiment 2

[0051] Step 1, the mass fraction of silicon carbide powder with a particle size of 45 μm, 20 μm, 5 μm, and 2 μm is mixed with silicon carbide short fibers with a mass fraction of 2% to 4% and graphite powder with a mass fraction of 8% in a ratio of 10:5:2:1 to obtain ceramic powder;

[0052]Step 2, adding citric acid with a content of about 0.2% of the powder weight to the ceramic powder to trigger the solidification reaction of the adhesive, after the preparation is completed;

[0053] Step 3: Perform dry ball milling for 30 minutes and fully mix to become silicon carbide-based ceramic powder for 3DP printing equipment;

[0054] Step 4, preparing the first adhesive, using colloidal silicon dioxide as the adhesive, distilled water as the medium, propylene glycol as the wetting agent, and triethanolamine as the base material, wherein the colloidal silicon dioxide and distilled water are in a mass ratio of 7 : 10 mixed, adding mass fraction is 5% propylene glycol, 3% triethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com