Method of laser brazing tool of monolayer diamond

A single-layer diamond and diamond tool technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of diamond graphitization, combustion, and large thermal deformation of the grinding wheel base, such as the brazing cycle, and achieve an increasing effect. The effect of distance, improving bonding strength, convenient and orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

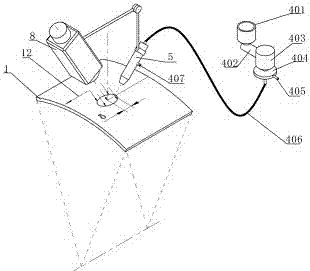

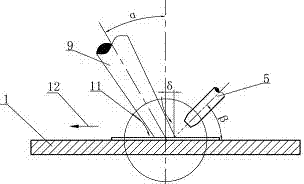

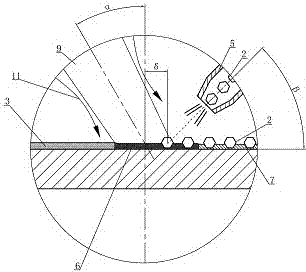

[0057] figure 1 -3 is a schematic diagram of the first embodiment of the present invention.

[0058] The equipment involved in this embodiment includes a laser brazing system and an injection system 4.

[0059] The laser brazing system includes a laser generator (not shown) and a laser brazing working head 8 connected to each other.

[0060] Such as figure 1 As shown, the spray system 4 includes a hopper 401, a feeder 402, a negative pressure chamber 403, a vacuum generator 404, a conveying gas inlet 405, a conveying pipe 406, a spray gun 5, and an atomizing gas inlet 407. Start the feeder when working, the diamond grit 2 in the hopper 401 is input into the feeder 402, the conveying gas enters the vacuum generator 404 from the conveying gas inlet 405, so that negative pressure is generated in the negative pressure chamber 403 and sucked into the diamond grinder input by the feeder 402 At the same time, the diamond abrasive particles 2 are transported to the spray gun 5 through the c...

Embodiment 2

[0081] The following will be attached Figure 4-5 Another technical solution of the present invention will be described in detail.

[0082] The difference from the above-mentioned first embodiment is that in this embodiment, a rectangular spot 10 is used to scan the solder, and three spray guns for spraying diamond abrasive grains 2 are arranged to form a spray gun group. The laser brazing system cooperates with the numerical control device to control the spraying The time sequence can realize the orderly arrangement of the diamond abrasive grains 2 to form a single-layer brazed diamond tool with the diamond abrasive grains 2 orderly arranged.

[0083] The specific method is as follows: Figure 4 As shown, a rectangular light spot 10 is used to scan the solder, and three spray guns spraying diamond abrasive grains 2 are configured to form a spray gun group. The spray gun group includes a No. 1 spray gun 501, a No. 2 spray gun 502, and a No. 3 spray gun 503. The caliber of each spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com