Additive manufacturing method for diamond tool

A diamond tool and additive manufacturing technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of short life of diamond tools and serious diamond graphitization, etc., reduce heat input, improve bonding strength, laser The effect of beam energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

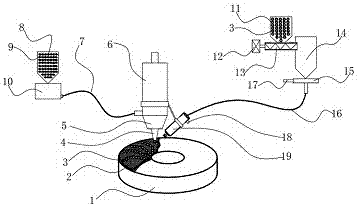

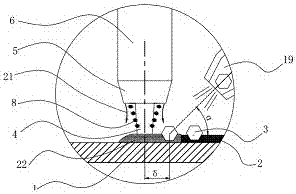

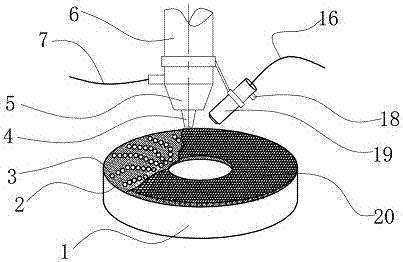

[0041] The following will be combined with Figure 1-5 The technical solutions of the embodiments of the present invention are described in detail.

[0042] Such as figure 1 As shown, the equipment used in this embodiment mainly includes a laser brazing system and a jetting system.

[0043] The injection system includes a feeder hopper 11 , a feeder 13 (a screw feeder is used in this embodiment), a vacuum chamber 14 , a feeding pipe 16 , and a spray gun 19 connected in sequence. The feeder 13 is also connected with a controller 12 , the vacuum chamber 14 is connected with a vacuum generator 15 , the vacuum generator 15 is provided with a conveying gas inlet 17 , and the spray gun 19 is provided with an atomizing gas inlet 18 .

[0044] The laser brazing system includes a laser generator (not shown), a powder feeding device and a laser brazing working head 6 connected to the laser generator. A coaxial nozzle 5 is arranged on the periphery of the laser brazing working head 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com