Method for Improving Diamond Seed Crystal Quality Using Hydrogen Plasma Multiple Etching/Annealing Cycle Process

A plasma and multiple etching technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of complex operation, deterioration of seed crystal surface quality, and long time consumption, and achieve simplified operation, Reduced risk of epitaxially grown diamond quality degradation, time and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

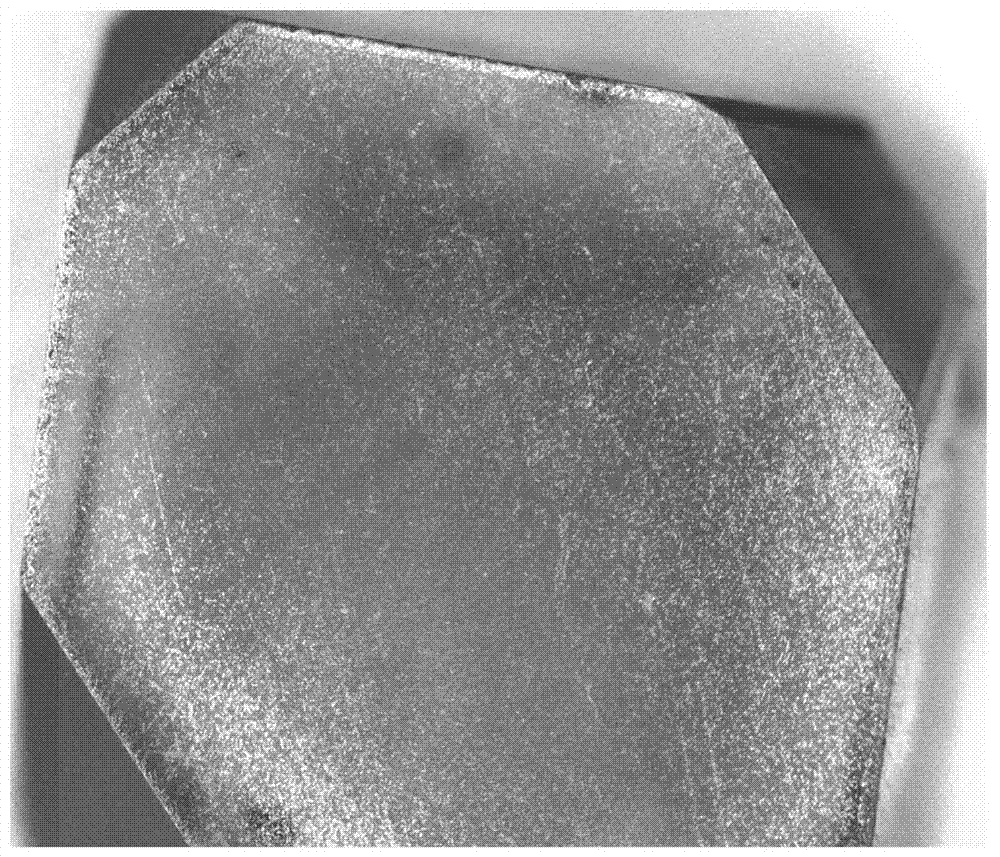

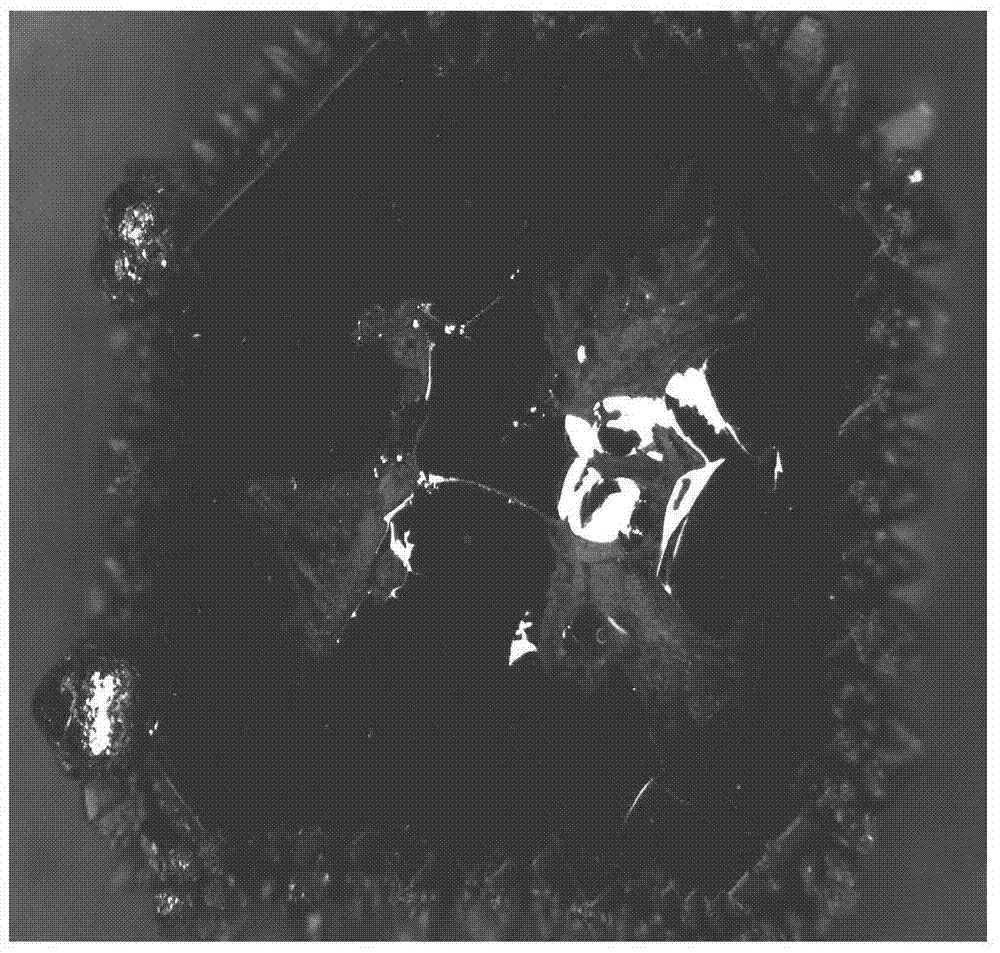

Image

Examples

specific Embodiment approach 1

[0026] Specific implementation mode one: the method for improving the quality of diamond seed crystals by using hydrogen plasma multiple etching / annealing cycle process in this embodiment comprises the following steps:

[0027] 1. Diamond seed crystal cleaning: Put the diamond seed crystal and the metal molybdenum substrate disc into acetone, deionized water, and absolute ethanol in sequence for ultrasonic cleaning. Each cleaning takes 15-30 minutes, and the ultrasonic power is 100-300W. Obtain the cleaned seed crystal and molybdenum alloy substrate;

[0028] 2. Welding: weld the cleaned seed crystal to the cleaned molybdenum substrate wafer with gold foil;

[0029] 3. Place the seed crystal: place the welded seed crystal on the heat insulation wire to keep the surface of the seed crystal level;

[0030] 4. Hydrogen plasma etching / annealing:

[0031] (1) Put the seed crystal treated in step 3 into the cabin, and after closing the cabin, vacuumize the cabin body so that the v...

specific Embodiment approach 2

[0042]Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ultrasonic power described in step one is 200W. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0043] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the cleaning time in step 1 is 20 minutes each time. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com