Titanium alloy powder injection molding special material and preparation method thereof

A powder injection molding and injection molding technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of high gap content, high cost, oxygen absorption, etc., and achieve the effect of low reactivity, less oxygen absorption, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

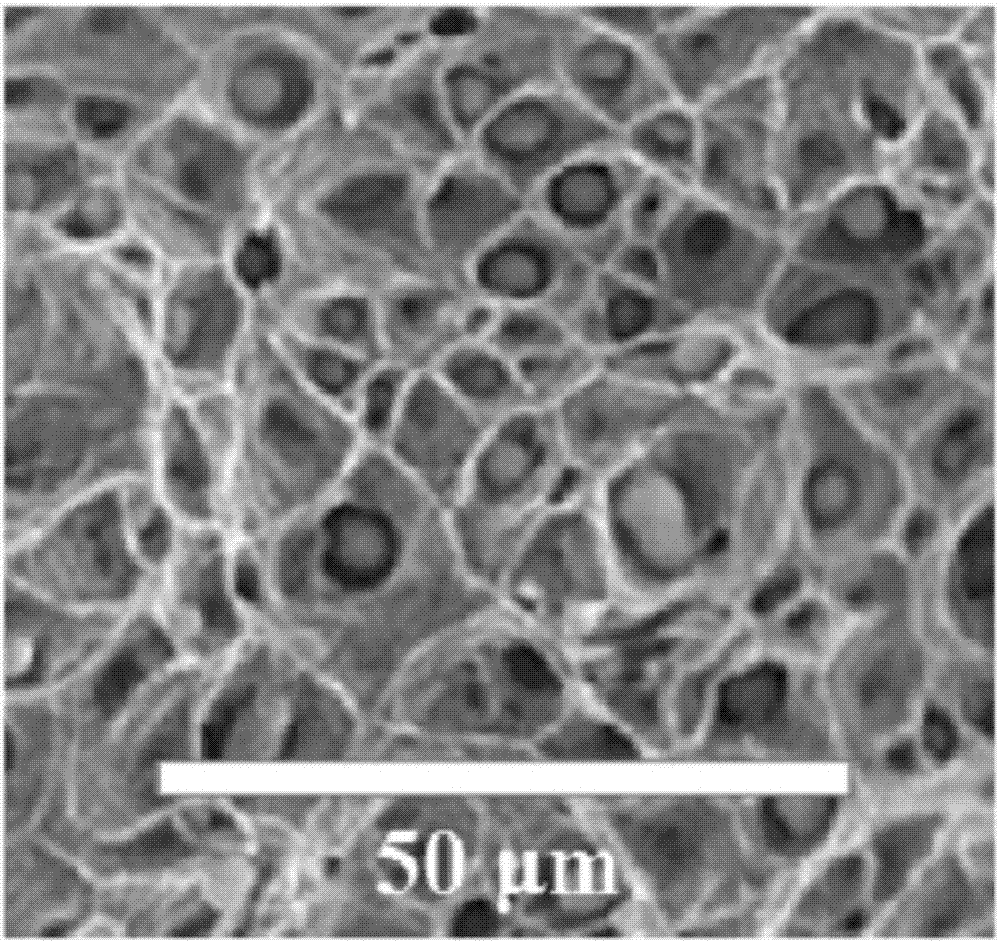

[0030] (1) Place coarse titanium alloy powder particles with a particle size of 60 μm in an aqueous solution of branched polyethyleneimine (Mw=10000) with a concentration of 2 g / L for adsorption for 30 minutes. The mass ratio of the particles to the aqueous solution is 1:4, and then use Wash the coarse titanium alloy powder particles with ion water for 10 minutes, then add 0.5 g / L negatively charged poly-p-styrene sodium sulfonate (Mw=10000) aqueous solution for adsorption for 30 minutes, the mass ratio of particles to aqueous solution is 1:4, Then wash with deionized water for 10 minutes, and then add 1 g / L positively charged TiO 2 (particle size 20nm) was adsorbed in the dispersion for 30 minutes, the mass ratio of the particles to the water dispersion was 1:4, and finally washed with deionized water for 10 minutes, and the above process was used to alternately deposit poly(p-styrene sodium sulfonate) and TiO 3 times 2 , so that the surface of the coarse titanium alloy powde...

Embodiment 2

[0036] (1) Place the coarse titanium alloy powder with a particle size of 65 μm in an aqueous solution of branched polyethyleneimine (Mw=40000) with a concentration of 3 g / L for adsorption for 30 minutes, the mass ratio of the particles to the aqueous solution is 1:4, and then deionized Wash the coarse titanium alloy powder particles with water for 10 minutes, then add 1.03 g / L negatively charged sodium hydroxymethyl cellulose (Mw=16000) aqueous solution for adsorption for 30 minutes, the mass ratio of the particles to the aqueous solution is 1:4, and then Wash with deionized water for 10 minutes, then add 2 g / L positively charged TiO 2 (particle size 30nm) was adsorbed in the dispersion for 30 minutes, the mass ratio of the particles to the aqueous dispersion was 1:4, and finally washed with deionized water for 10 minutes, and the above process was used to alternately deposit sodium hydroxymethyl cellulose and TiO 8 times 2 , so that the surface of the coarse titanium alloy p...

Embodiment 3

[0041] (1) Put the coarse titanium alloy powder with a particle size of 70 μm in an aqueous solution of branched polyethyleneimine (Mw=60000) with a concentration of 4 g / L for adsorption for 30 minutes. The mass ratio of particles to aqueous solution is 1:4, and then deionized Wash the coarse titanium alloy powder particles with water for 10 minutes, then add 1.5g / L negatively charged polyacrylic acid (Mw=70000) aqueous solution for adsorption for 30 minutes, the mass ratio of particles to aqueous solution is 1:4, and then deionized water Wash with water for 10 minutes, then add 3g / L positively charged TiO 2 (particle size 40nm) in the dispersion for 30 minutes, the mass ratio of the particles to the water dispersion was 1:4, and finally washed with deionized water for 10 minutes, using the above process for a total of 11 alternate depositions of polyacrylic acid and TiO 2 , so that the surface of the coarse titanium alloy powder particles adsorbs the polyelectrolyte / titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com