Preparation device and method for increasing formation size of aluminum-based amorphous alloy

An amorphous alloy and preparation device technology, which is applied in the direction of metal processing equipment, indicating equipment/measurement equipment configuration, manufacturing tools, etc., can solve the problems of lack of temperature measurement means and difficulty in capturing temperature changes, so as to ensure rapid heat dissipation and improve Effects of cooling rate and increasing melt pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

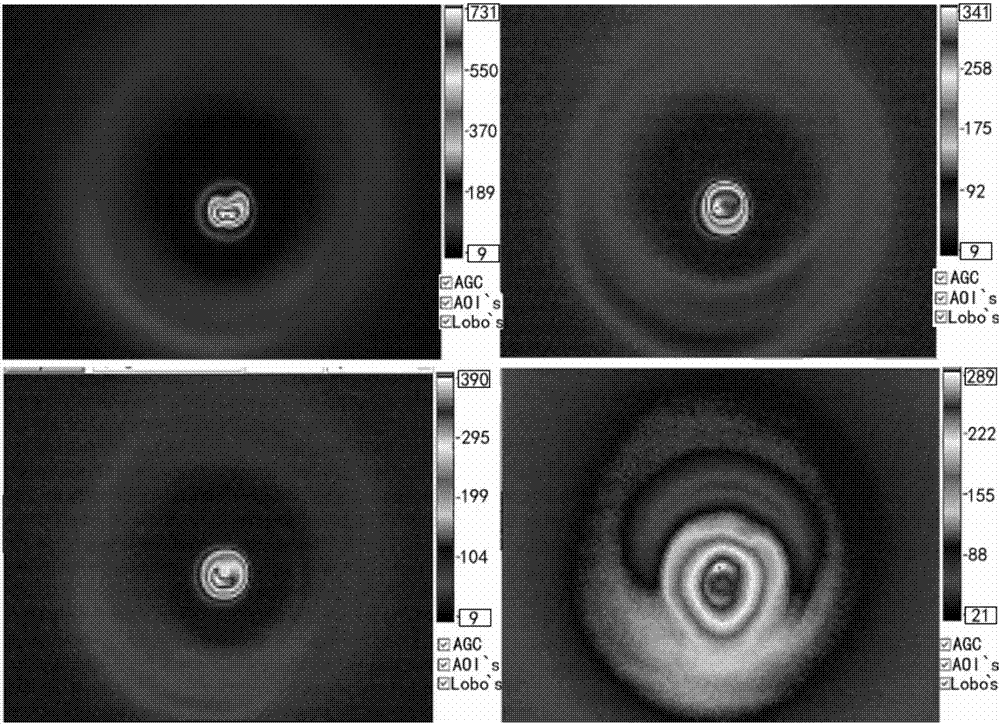

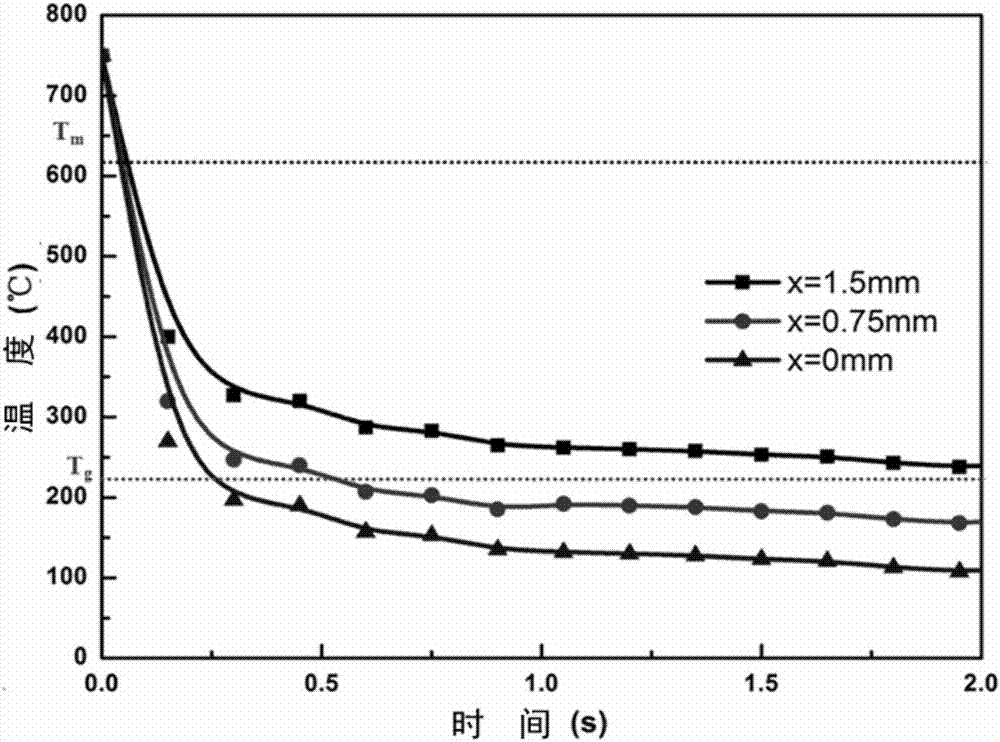

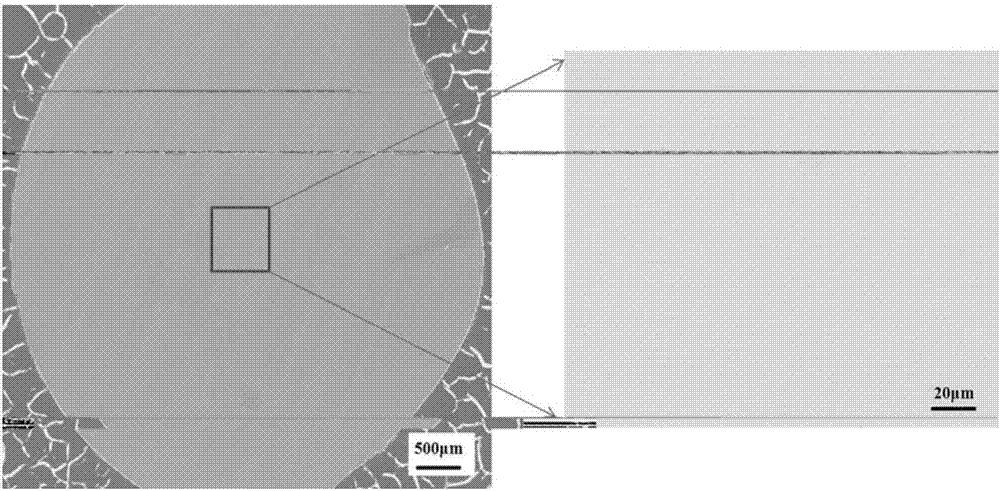

[0040] see figure 1 and figure 2 structure shown. The preparation device of the present invention is used to prepare large-size bulk Al-based amorphous alloy rods, and aims to improve the glass-forming ability of Al-based amorphous alloys from the perspective of preparation process optimization. like figure 1 As shown, the ejector pin 1 hollowed out in the center of the preparation structure can facilitate the real-time monitoring of the temperature of the Al-based amorphous sample in the copper mold 2 by the infrared thermometer 12, and the mechanical pump exhaust port 3 and the molecular pump exhaust port 4 can ensure a sealed cavity The good vacuum degree within 11 can be read by vacuum gauge according to the requirements to get the ideal vacuum condition. The protective gas inlet 5 can be fed with protective gases such as helium and argon to further ensure a good atmosphere in the sealed cavity 11, ensure that the oxygen content in the cavity 11 reaches the minimum to ...

Embodiment 2

[0052] The difference from Example 1 is that when the angle between the gas channel in the copper mold and the central mold column is 90°, shrinkage cavities and porosity appear in the prepared sample, and the cooling rate is low after the conversion of the measured temperature, and finally The samples obtained had low amorphousness.

Embodiment 3

[0054] The difference from Example 1 is that when the melt temperature is 750° C., the cooling rate is extremely low after conversion of the measured temperature during the preparation process, and the prepared sample has few amorphous regions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com