Preparation method and application of first-class solid polymer electrolyte

A solid polymer and polymer technology, applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of low ionic conductivity, achieve simple preparation method, improve flexibility, and facilitate large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

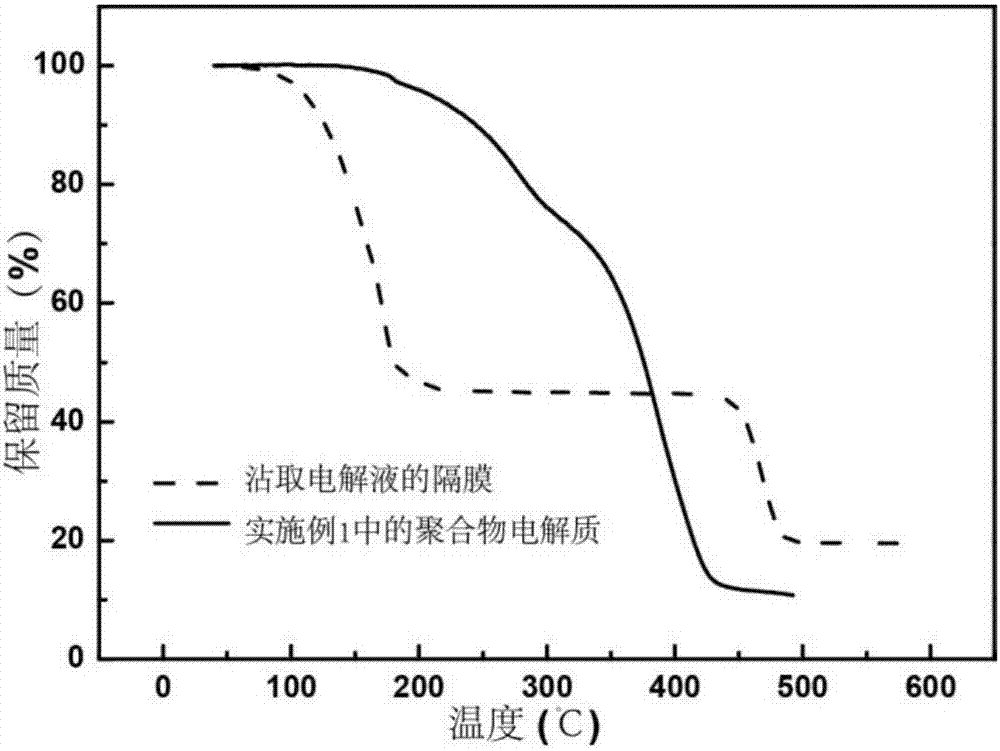

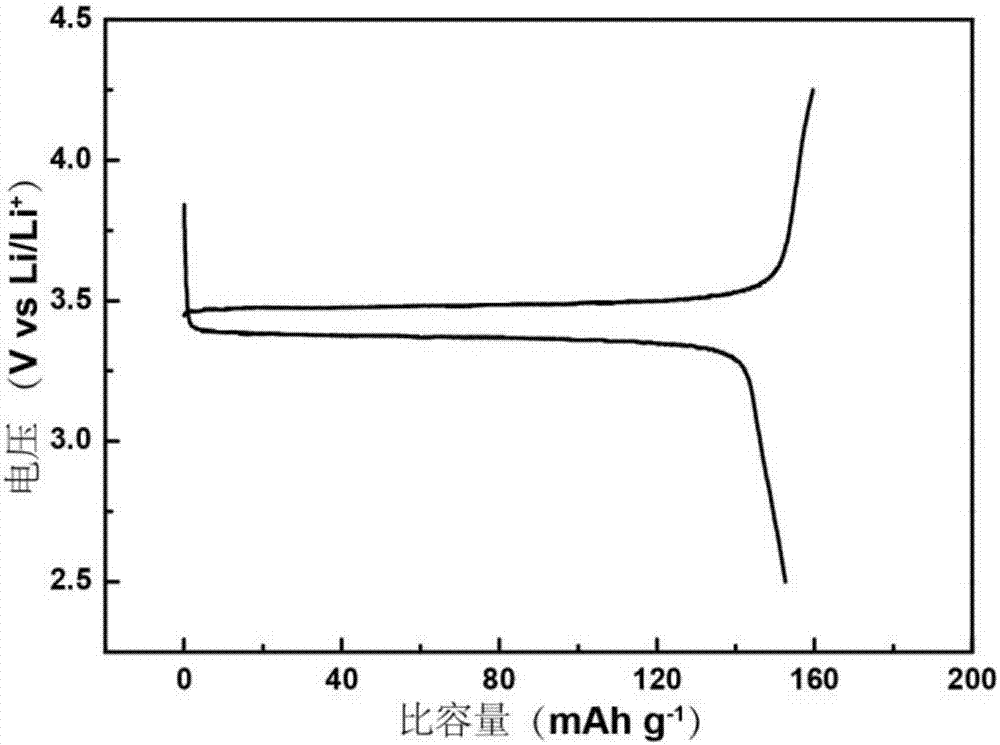

Embodiment 1

[0035] (1) Preparation of the polymer electrolyte precursor solution: according to the mass ratio of 10:3, the poly(dimethylsiloxane) diglycidyl ether was capped, and the amino polystyrene microspheres were mixed evenly, and kept for 2 hours. On the premise that the molar ratio of ethylene glycol diacrylate to poly(dimethylsiloxane) diglycidyl ether end-blocking is 1:1, add Li[B(C2O4)2] with a mass ratio of 3:10:0.1 , polyethylene glycol diacrylate, and initiator benzoyl peroxide are mixed uniformly at room temperature. Wherein, the particle diameter of the aminopolystyrene microspheres is 50nm.

[0036] (2) Preparation of solid polymer electrolyte: the precursor solution obtained in step 1 was evenly coated on the polytetrafluoroethylene substrate at a ratio of 50 microliters per square centimeter, and thermally polymerized in an oven at 200° C. for 5 hours.

[0037] (3) Preparation of lithium iron phosphate cathode material: mix lithium iron phosphate, the polymer precursor...

Embodiment 2

[0041] Except changing thermal initiator benzoyl peroxide into photoinitiator 1-hydroxycyclohexyl phenyl ketone in embodiment 1 (1), and changing thermal polymer polyethylene glycol diacrylate into photopolymerization 1,4-butanediol diacrylate was polymerized for 30 minutes at a distance of 10 cm from a 2 kW UV lamp. Other conditions are exactly the same, and the test performance is listed in Table 1.

Embodiment 3

[0043] Except changing thermal initiator into microwave initiator azobisisobutyronitrile in embodiment 1 (1), thermal polymer is changed into microwave polymer vinyl acetate, at 10GHz, polymerization 20min under the power of 1000w, other conditions In full agreement, the test performance is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com