Preparation method of PBT silver-ion antibiotic moisture-absorption deodorization fibre

A silver ion and fiber technology is applied in the field of preparation of PBT silver ion antibacterial, moisture-absorbing and deodorizing fibers, which can solve problems such as no reports on PBT silver-ion antibacterial, moisture-absorbing and deodorizing fibers, and achieve excellent chemical resistance, good durability, Good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

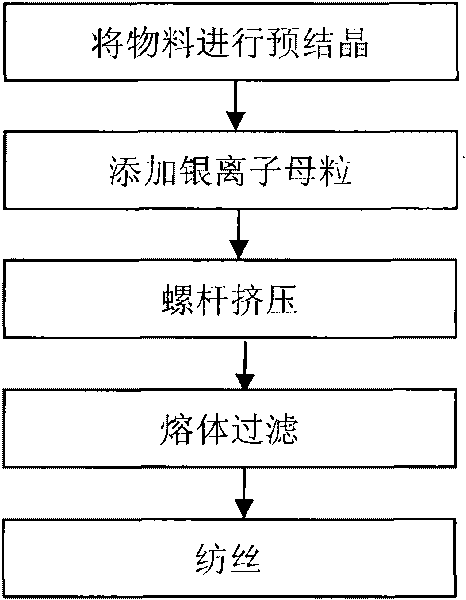

[0013] In conjunction with accompanying drawing, the preparation method of a kind of PBT silver ion antibacterial hygroscopic deodorant fiber of the present invention comprises the following steps:

[0014] Step 1. Pre-crystallize the material, which is a mixture of PBT slices and silver ion SHT antibacterial plastic masterbatch; specifically, dry hot air is used for pre-crystallization; when the material is pre-crystallized, the pre-crystallization temperature is 120-125°C , The temperature of the dry hot air is 130-135°C, the air dew point is less than or equal to -60°C, the moisture content of the material is 30ppm, and the drying time is 8-10 hours.

[0015] Step 2. Material screw feeding: first dry the color masterbatch with hot air, then feed the mixed material of the color masterbatch and PBT chips into the screw extruder through a special color masterbatch feeder that can measure the color masterbatch Middle; when the material is screw-fed, the material is a mixture of...

Embodiment 1

[0020] A preparation method of PBT silver ion antibacterial, moisture-absorbing and deodorant fiber, comprising the following steps:

[0021] Step 1. Pre-crystallize the material, which is a mixture of PBT slices and silver ion SHT antibacterial plastic masterbatch; specifically, dry hot air is used for pre-crystallization; when the material is pre-crystallized, the pre-crystallization temperature is 120 ° C, and the The temperature of the hot air is 130°C, the air dew point is -60°C, the moisture content of the material is 30ppm, and the drying time is 8 hours.

[0022] Step 2. Material screw feeding: first dry the color masterbatch with hot air, then feed the mixed material of the color masterbatch and PBT chips into the screw extruder through a special color masterbatch feeder that can measure the color masterbatch Middle; when the material is screw-fed, the material is a mixture of PBT (polybutylene terephthalate) slices and silver ion SHT (nano silver inorganic antibacter...

Embodiment 2

[0026] A preparation method of PBT silver ion antibacterial, moisture-absorbing and deodorant fiber, comprising the following steps:

[0027] Step 1. Pre-crystallize the material, which is a mixture of PBT slices and silver ion SHT antibacterial plastic masterbatch; specifically, dry hot air is used for pre-crystallization; when the material is pre-crystallized, the pre-crystallization temperature is 125 ° C, and the drying The temperature of the hot air is 135°C, the air dew point is -55°C, the moisture content of the material is 30ppm, and the drying time is 10 hours.

[0028] Step 2. Material screw feeding: first dry the color masterbatch with hot air, then feed the mixed material of the color masterbatch and PBT chips into the screw extruder through a special color masterbatch feeder that can measure the color masterbatch Middle; when the material is screw-fed, the material is a mixture of PBT (polybutylene terephthalate) slices and silver ion SHT (nano silver inorganic an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com