Warm pressing deformation biological magnesium alloy and preparation method thereof

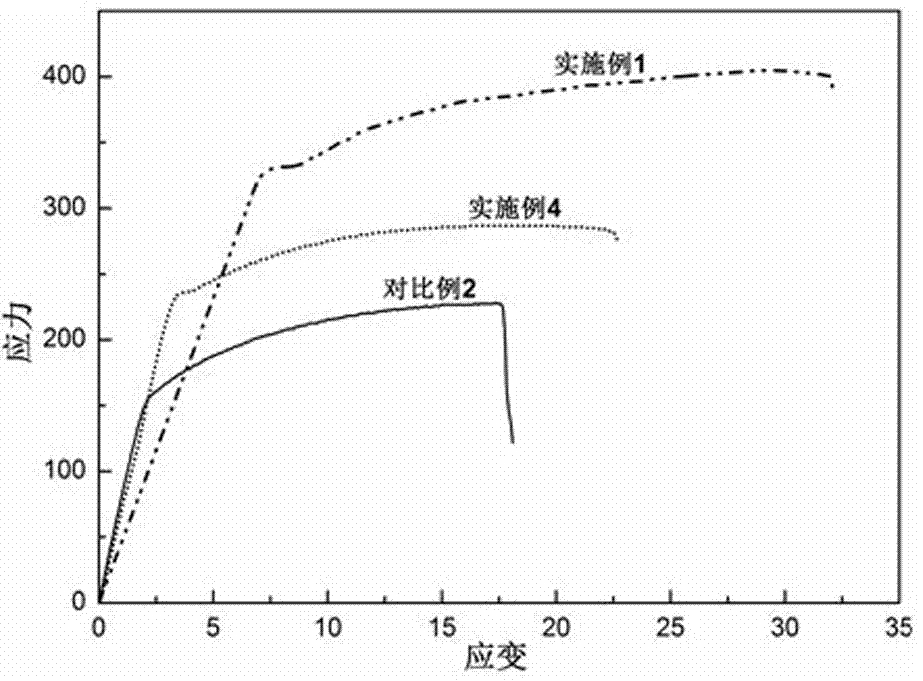

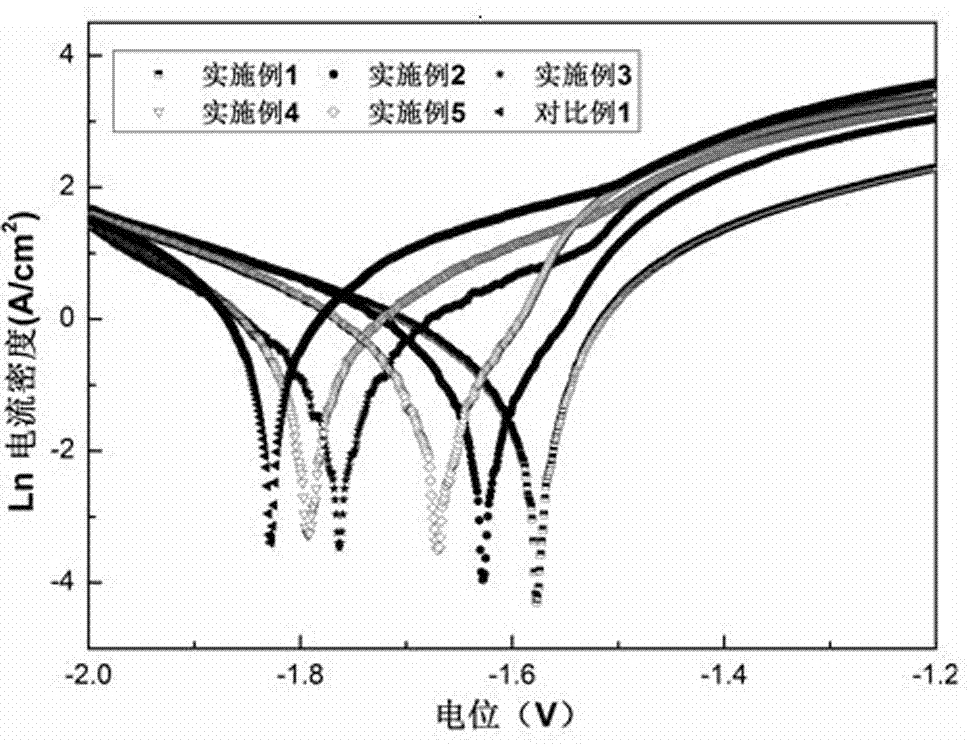

A magnesium alloy and warm pressing technology is applied in the field of warm pressing deformation biological magnesium alloy and its preparation, which can solve the problems of reduced corrosion resistance of the alloy, reduced corrosion resistance of the alloy, coarse grains of the magnesium alloy, etc., and achieves uniform grain size. Small, improved molding rate, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

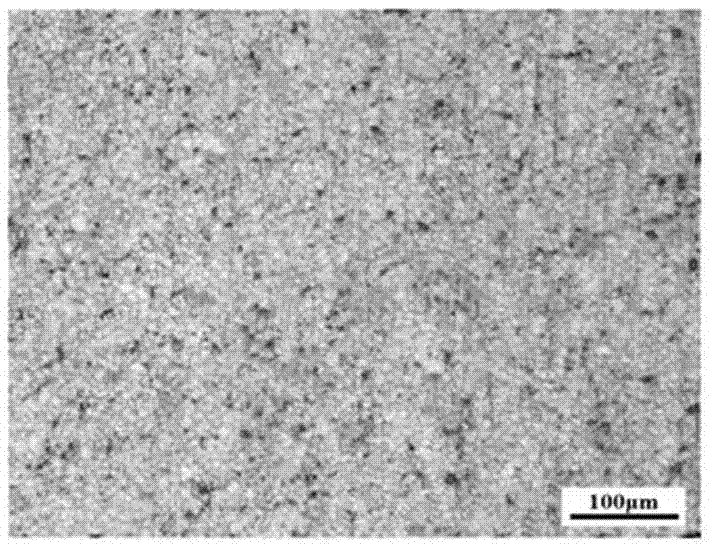

[0030] Mg-6Zn-0.5Mn-0.3Gd warm-press deformation biological magnesium alloy, the preparation method is:

[0031] 1) Prepare as-cast Mg-6Zn-0.5Mn-0.3Gd alloy masterbatch samples according to the nominal weight percentage of each element;

[0032] 2) Put the sample in step 1) at room temperature for natural aging for 150 hours, then move it into a box-type resistance furnace, keep it at 320°C for 15 hours, and then cool it with the furnace;

[0033] 3) Heat the sample treated in step 2) to 220°C for extrusion pretreatment, and then put it into a 1000T forward extrusion machine. The furnace chamber temperature of the extruder is 320°C. The upsetting ratio is 0.5, and then extrusion is carried out, the extrusion ratio is 13, the extrusion speed is 133mm / s, and the sample is extruded into a round bar with a diameter of 30mm;

[0034] 4) The sample extruded into a round bar in step 3) was subjected to aging treatment, the aging treatment was 180°C for 24 hours, and air cooling to o...

Embodiment 2

[0037] Mg-4.5Zn-0.8Mn-0.5Gd warm-press deformation biological magnesium alloy, the preparation method is:

[0038] 1) Prepare as-cast Mg-4.5Zn-0.8Mn-0.5Gd alloy masterbatch samples according to the nominal weight percentage of each element;

[0039] 2) Put the sample in step 1) at room temperature for natural aging for 180 hours, then move it into a box-type resistance furnace, keep it at 340°C for 12 hours, and then cool it with the furnace;

[0040]3) Heat the sample treated in step 2) to 240°C for extrusion pretreatment, and then put it into a 1000T forward extrusion machine. The furnace chamber temperature of the extruder is 320°C, and upset the sample first. The upsetting ratio is 0.5, and then extrusion is carried out, the extrusion ratio is 13, the extrusion speed is 133mm / s, and the sample is extruded into a round bar with a diameter of 30mm;

[0041] 4) The sample extruded into a round bar in step 3) was subjected to aging treatment, the aging treatment was 200°C for...

Embodiment 3

[0044] Mg-4Zn-1Mn-0.6Gd warm-press deformation biological magnesium alloy, the preparation method is:

[0045] 1) Prepare as-cast Mg-4Zn-1Mn-0.6Gd alloy masterbatch samples according to the nominal weight percentage of each element;

[0046] 2) Put the sample in step 1) at room temperature for natural aging for 160 hours, then move it into a box-type resistance furnace, keep it at 350°C for 18 hours, and then cool it with the furnace;

[0047] 3) Heat the sample treated in step 2) to 200°C for extrusion pretreatment, and then put it into a 1000T forward extruder. The temperature of the furnace chamber of the extruder is 320°C. The upsetting ratio is 0.6, and then extrusion is performed, the extrusion ratio is 15, the extrusion speed is 160mm / s, and the sample is extruded into a round bar with a diameter of 33mm;

[0048] 4) The sample extruded into a round rod in step 3) was subjected to aging treatment, and the aging treatment was 160°C for 36 hours, and air cooling to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com