Preparation method of aqueous polyurethane/fluorinated phosphazene nano fiber composite material

A fluorine-containing polyphosphazene and water-based polyurethane technology is applied in the field of nanomaterial preparation, which can solve the problems of nanoparticle structure and morphology damage, composite material comprehensive performance decline, inconvenient production process, etc., and achieves excellent thermal stability and improved thermal stability. The effect of stable performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

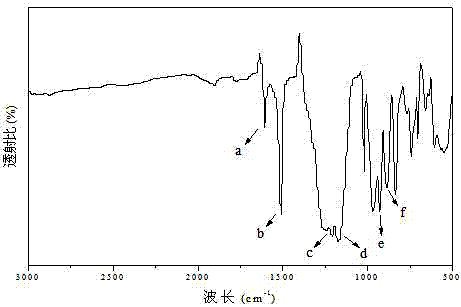

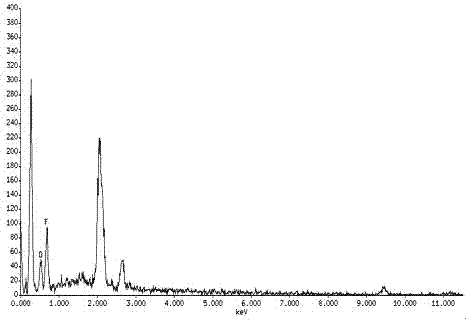

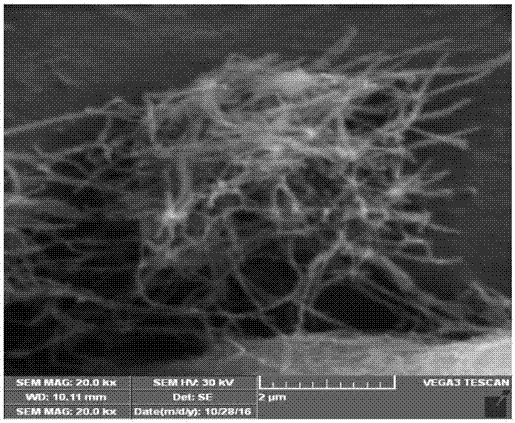

[0026] Step 1: Under magnetic stirring at 1200 r / min, add 0.1 g of hexachlorocyclotriphosphazene and 0.28 g of 4,4'-(hexafluoroisopropylidene ) bisphenol, slowly added 0.24 mL triethylamine, reacted at room temperature for 12 hours, washed three times with deionized water and ethanol, centrifuged at 4000 r / min, and dried in vacuum at 40°C for 24 hours to obtain fluorine-containing polyphosphazene nanoparticles Fiber, 80% yield.

[0027] Step 2: Put 30 g of PPG-2000 in a three-necked flask, and fill it with nitrogen (without fiber). Stir continuously in an oil bath at 100° C. for 0.5 hours, add 11.67 g of IPDI and 5 drops of dibutyltin dilaurate catalyst, and react at 95° C. for 2 hours. 2.01 g of DMPA, which had been vacuum-dried in advance, was added into the three-necked flask, and the reaction was continued for 3 hours. Lower the temperature of the system to 30°C, add TEA to neutralize to pH 7, and stir at constant temperature for 0.5 h to obtain a PU prepolymer. The pre...

Embodiment 2

[0029] Step 1: Under magnetic stirring at 1200 r / min, add 0.2 g of hexachlorocyclotriphosphazene and 0.38 g of 4,4'-(hexafluoroisopropylidene) into a single-necked flask containing 100 mL of toluene acetone solution Bisphenol, slowly add 0.48 mL triethylamine, react at room temperature for 12 hours, wash with deionized water and ethanol three times respectively, centrifuge at 4000 r / min, and vacuum dry at 40°C for 24 hours to obtain fluorine-containing polyphosphazene nanofibers , and the yield was 81%.

[0030] Step 2: Put 30 g of PPG-2000 in a three-necked flask, add 0.2552 g (0.5 wt.%) fluorine-containing polyphosphazene fiber at the same time, and fill it with nitrogen for protection. Stir continuously in an oil bath at 100° C. for 0.5 hours, add 11.67 g of IPDI and 5 drops of dibutyltin dilaurate catalyst, and react at 95° C. for 2 hours. 2.01 g of DMPA, which had been vacuum-dried in advance, was added into the three-necked flask, and the reaction was continued for 3 ho...

Embodiment 3

[0032]Step 1: Under magnetic stirring at 1200 r / min, add 0.4 g of hexachlorocyclotriphosphazene and 1.0 g of 4,4'-(hexafluoroisopropylidene ) bisphenol, slowly add 0.96mL triethylamine, react at room temperature for 12 hours, wash with deionized water and ethanol three times respectively, centrifuge at 4000 r / min, and vacuum dry at 40°C for 24 hours to obtain fluorine-containing polyphosphazene Nanofibers with a yield of 83%.

[0033] Step 2: Put 30 g of PPG-2000 in a three-necked flask, add 0.5104 g (1.0 wt.%) fluorine-containing polyphosphazene fiber at the same time, and fill it with nitrogen for protection. Stir continuously in an oil bath at 100° C. for 0.5 hours, add 11.67 g of IPDI and 5 drops of dibutyltin dilaurate catalyst, and react at 95° C. for 2 hours. 2.01 g of DMPA, which had been vacuum-dried in advance, was added into the three-necked flask, and the reaction was continued for 3 hours. Lower the temperature of the system to 30°C, add TEA to neutralize to pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com