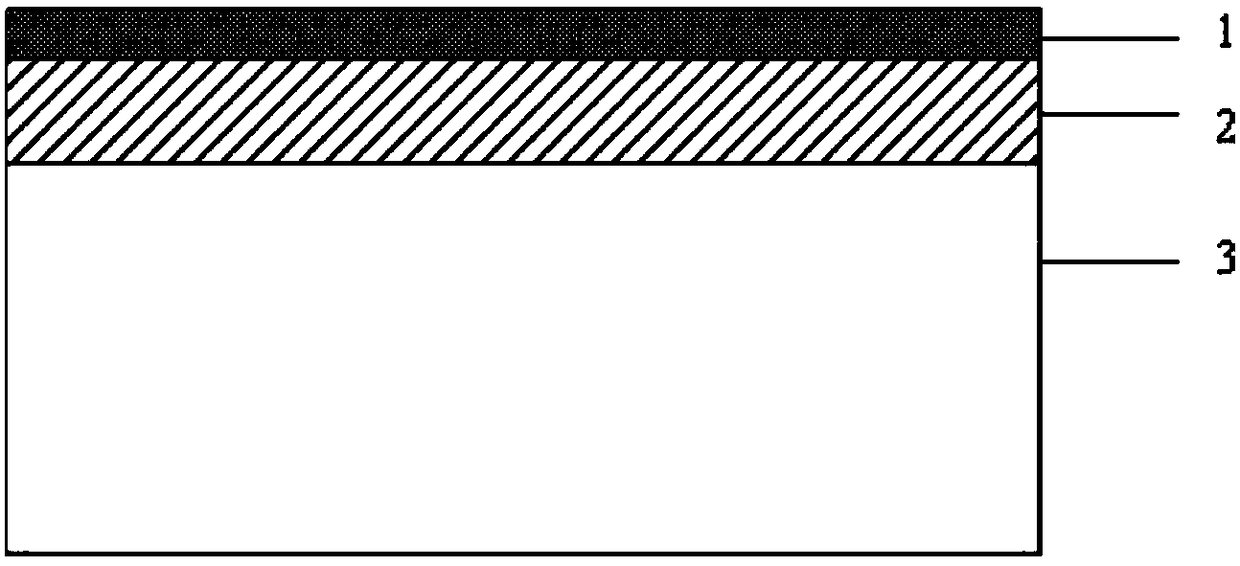

A metal hydride surface composite hydrogen-resistant permeation layer and its preparation method

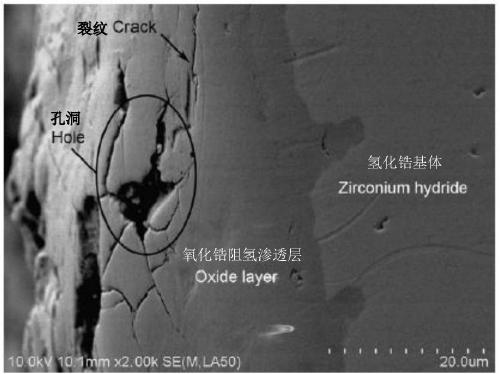

A surface compounding and hydride technology, which is applied in metal material coating process, coating, liquid chemical plating, etc., can solve the problems of easy generation of microcracks, interlayer defects, easy peeling, etc., and achieve enhanced hydrogen resistance penetration ability , no obvious cracks, not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

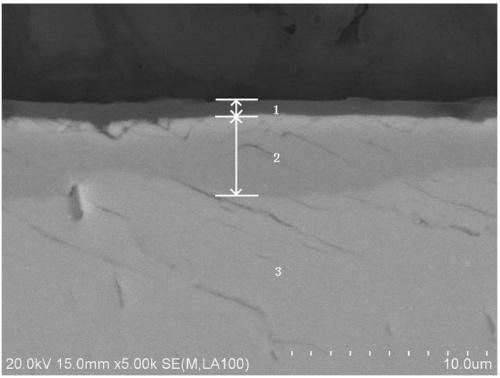

Image

Examples

Embodiment 1

[0034] (1) The edge of the metal zirconium hydride substrate with Φ20mm×20mm and H / Zr atomic ratio of 1.85 is chamfered at an angle of 45°, the chamfering radius is 1.5mm, the surface is polished, ultrasonically cleaned with acetone and dried. The surface of zirconium hydride was coated with organosilicon sol by dipping and pulling method, and the thickness of the coating was controlled to be about 1 μm. The temperature was raised to 50°C, 120°C, 180°C, and 250°C at a heating rate of 300°C / h, and the temperature was kept at 50°C, 120°C, 180°C, and 250°C for 100 hours, and then the sample was cooled at a cooling rate of 100°C / h to room temperature.

[0035](2) Seal the zirconium hydride substrate with a dry organic silica sol coating in a stainless steel reaction vessel with a vacuum tube and a ventilation tube, place the reaction vessel in a temperature-controlled tubular heating furnace, and evacuate the reaction vessel to 3.0 ×10 -4 Pa; after that, 5%, 15%, and 80% of CO a...

Embodiment 2

[0039] (1) The edge of the zirconium hydride matrix with Φ30mm×40mm and H / Zr atomic ratio of 2.0 is chamfered at an angle of 45°, the chamfering radius is 2mm, the surface is polished, ultrasonically cleaned with acetone and dried. The surface of zirconium hydride was coated with organosilicon sol coating modified by nano-alumina sol by dipping and pulling method, and the thickness of the coating was controlled to be about 2 μm. The temperature was raised to 120°C and 200°C sequentially at a heating rate of 50°C / h, and the temperature was kept at 120°C and 200°C for 1 hour respectively, and then the sample was cooled to room temperature at a cooling rate of 300°C / h.

[0040] (2) Seal the zirconium hydride substrate with a dry organic silica sol coating in a quartz reaction vessel with a vacuum tube and a vent tube, place the reaction vessel in a temperature-controlled heating furnace, and evacuate the reaction vessel to vacuum to 1×10 -5 Pa; then into the reaction vessel into...

Embodiment 3

[0042] (1) The edge of the hafnium hydride matrix with Φ20mm×50mm and H / Hf atomic ratio of 1.75 is inverted at an angle of 45°, the surface is polished, ultrasonically cleaned with acetone, and then dried. The surface of hafnium hydride was plated with organosilicon sol coating modified by nanometer oxide bait sol by dipping and pulling method, and the coating thickness was controlled to be about 3 μm. The temperature was raised to 50°C, 120°C, and 180°C at a heating rate of 300°C / h, and the temperature was kept at 50°C, 120°C, and 180°C for 30 hours, and then the sample was cooled to room temperature at a cooling rate of 50°C / h.

[0043] (2) Seal the hafnium hydride substrate with a dry organic silicon sol coating in a heat-resistant glass reaction vessel with a vacuum tube and a vent tube, place the reaction vessel in a temperature-controlled heating furnace, and evacuate the reaction vessel to a vacuum. Vacuum to 100Pa; after that, 80%, 15%, and 5% CO by volume are introduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com