A kind of reuse method of waste liquid after extracting sisal saponin from sisal

A technology of sisal saponin and waste liquid, applied in chemical instruments and methods, multi-stage water/sewage treatment, filtration treatment, etc., can solve the problems of high sugar content, large chroma pollution, difficult waste water, etc., and achieve improvement Oxygen content and PH value, reducing the content of acid and salt, improving the effect of PH value and chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

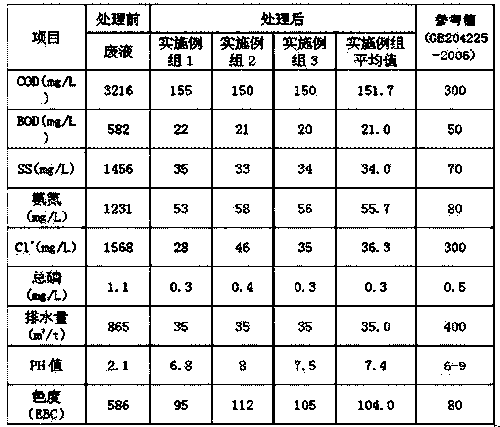

Examples

Embodiment 1

[0033] The recycling method of waste liquid after extracting sisal saponin from sisal, is characterized in that, comprises the following steps:

[0034] a. Measure the ion content of sulfate, oxalate and chloride ions in the waste liquid;

[0035] b. Add phosphate rock powder with a particle size of 200 meshes to the waste liquid, and the taste of the phosphate rock powder is 31%P 2 O 5 , the ratio of the added phosphate rock powder and the sulfate radical equivalent is 1:1, and stir evenly, wherein the phosphate rock powder and the sulfate radical react to generate calcium superphosphate crystals and calcium sulfate and release hydrogen fluoride gas, the hydrogen fluoride gas and phosphate rock powder Silica and silicate react to generate silicon tetrafluoride, the escape gas is collected and introduced into the water washing tower to obtain a fluorosilicic acid solution with a solute mass fraction of 25%, and the calcium sulfate reacts with oxalic acid in the waste liquid t...

Embodiment 2

[0040] The recycling method of waste liquid after extracting sisal saponin from sisal, is characterized in that, comprises the following steps:

[0041] a. Measure the ion content of sulfate, oxalate and chloride ions in the waste liquid;

[0042] b. Add phosphate rock powder with a particle size of 100 meshes to the waste liquid, and the taste of the phosphate rock powder is 33%P 2 O 5 , the ratio of the added phosphate rock powder and the sulfate radical equivalent is 1:3.5, and stir evenly, wherein the phosphate rock powder reacts with the sulfate radical to generate calcium superphosphate crystals and calcium sulfate and release hydrogen fluoride gas, the hydrogen fluoride gas and the phosphate rock powder. Silica and silicate react to generate silicon tetrafluoride, the escape gas is collected and introduced into a water washing tower to obtain a fluorosilicic acid solution with a solute mass fraction of 30%, and the calcium sulfate reacts with oxalic acid in the waste l...

Embodiment 3

[0047] The recycling method of waste liquid after extracting sisal saponin from sisal, is characterized in that, comprises the following steps:

[0048] a. Measure the ion content of sulfate, oxalate and chloride ions in the waste liquid;

[0049] b. Add phosphate rock powder with a particle size of 150 meshes to the waste liquid, and the taste of the phosphate rock powder is 35%P 2 O 5 , the ratio of the added phosphate rock powder and the sulfate radical equivalent is 1:2, and stir evenly, wherein the phosphate rock powder and the sulfate radical react to generate calcium superphosphate crystals and calcium sulfate and release hydrogen fluoride gas, the hydrogen fluoride gas and phosphate rock powder Silica and silicate react to generate silicon tetrafluoride, the escape gas is collected and introduced into the water washing tower to obtain a fluorosilicic acid solution with a solute mass fraction of 25%, and the calcium sulfate reacts with oxalic acid in the waste liquid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com