Anti-fatigue low-carbon high-chromium steel ball

A high-chromium steel ball, low-carbon and high-chromium technology, applied in coating, furnace type, furnace, etc., can solve the problems of low fatigue resistance, crack resistance, poor anti-falling fatigue performance, low toughness, etc., to achieve Effects of increasing strength, reducing notch sensitivity, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

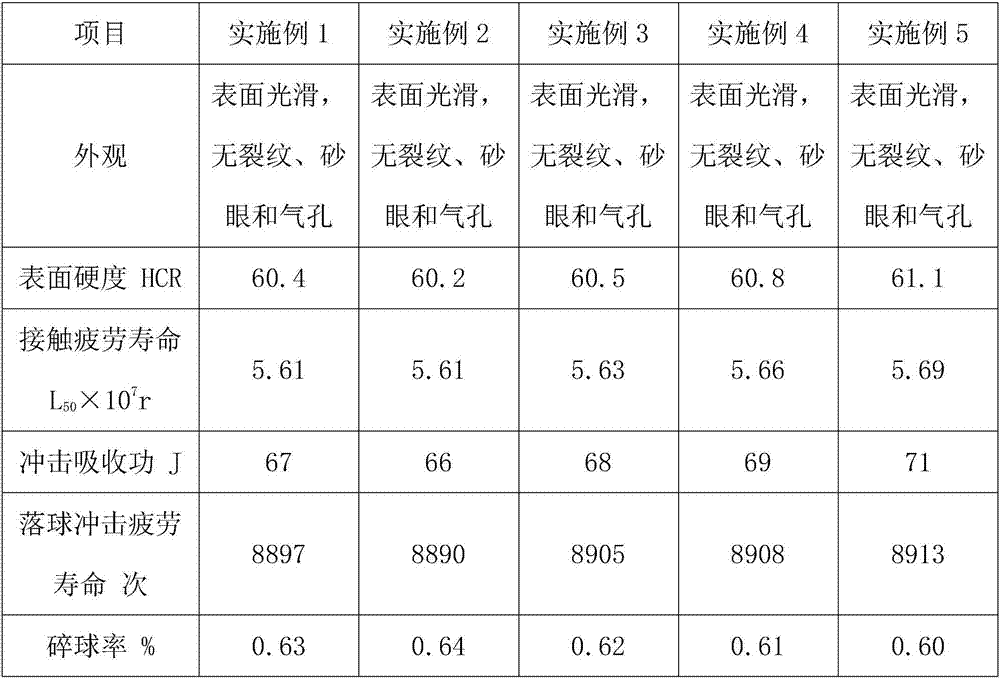

Examples

Embodiment 1

[0018] An anti-fatigue low-carbon high-chromium steel ball, the weight percentage of each component is as follows: C: 0.17%, Cr: 14%, V: 0.35%, Co: 0.55%, W: 0.1%, Si: 0.25%, Mn: 0.3%, Mo: 1.1%, S≤0.015%, P≤0.015%, Ni: 0.6%, and the balance is Fe.

Embodiment 2

[0020] An anti-fatigue low-carbon high-chromium steel ball, the weight percentage of each component is as follows: C: 0.15%, Cr: 15%, V: 0.3%, Co: 0.6%, W: 0.05%, Si: 0.3%, Mn: 0.2%, Mo: 1.2%, S≤0.015%, P≤0.015%, Ni: 0.8%, the remainder is Fe;

[0021] In the preparation process of anti-fatigue low-carbon high-chromium steel balls, scrap steel is smelted, carbon, chromium, vanadium, cobalt, nickel, tungsten, silicon, manganese, molybdenum are added, rough smelted, refined, cast out of the furnace to obtain a spherical shape that meets the above components Ingot casting, wherein the casting temperature is 1400°C; take a spherical ingot, heat it up to 950°C, keep it warm for 50 minutes, cool it down to room temperature at a speed of 3.5°C / s, then raise the temperature to 520°C, hold it for 6 hours, polish and clean it Process to obtain the intermediate ingot; take the intermediate ingot and heat it up to 560°C in an ammonia atmosphere, hold it for 32 hours and then cool it to ro...

Embodiment 3

[0023] An anti-fatigue low-carbon high-chromium steel ball, the weight percentage of each component is as follows: C: 0.2%, Cr: 13%, V: 0.4%, Co: 0.5%, W: 0.15%, Si: 0.2%, Mn: 0.4%, Mo: 1%, S≤0.015%, P≤0.015%, Ni: 0.55%, the remainder is Fe;

[0024] In the preparation process of anti-fatigue low-carbon high-chromium steel balls, scrap steel is smelted, carbon, chromium, vanadium, cobalt, nickel, tungsten, silicon, manganese, molybdenum are added, rough smelted, refined, cast out of the furnace to obtain a spherical shape that meets the above components Ingot casting, wherein the casting temperature is 1440°C; take a spherical ingot, heat it up to 900°C, keep it warm for 70 minutes, cool it down to room temperature at a rate of 2.5°C / s, then raise the temperature to 540°C, hold it for 4 hours, polish and clean Process to obtain the intermediate ingot; take the intermediate ingot and heat it up to 580°C in an ammonia atmosphere, hold it for 28 hours and then cool it to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeable layer thickness | aaaaa | aaaaa |

| Permeable layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com