Method for step-by-step extraction of copper anode mud silver separating residues

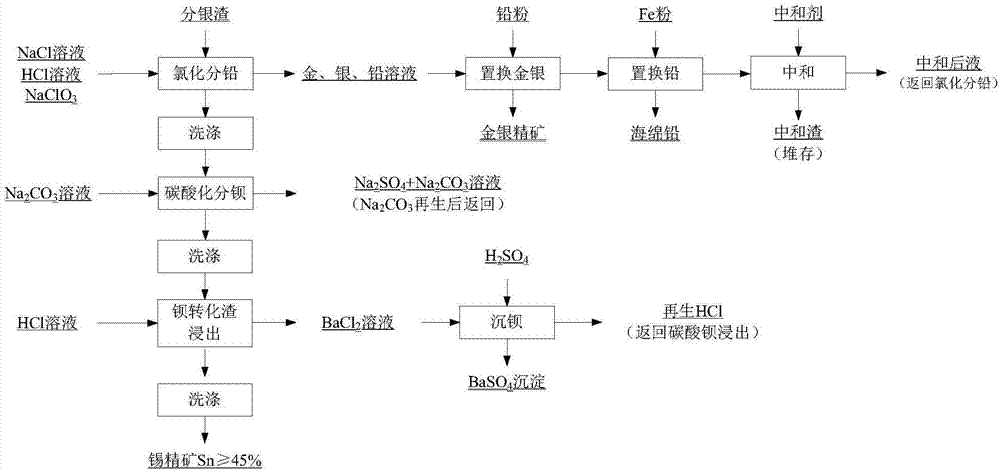

A copper anode slime and silver slag separation technology, applied in the step-by-step extraction of Sn, copper anode slime silver slag, Ag, Ba, comprehensive recovery of Au, Pb in copper anode slime silver slag, can solve the comprehensive problem of lead, tin and barium Low utilization, low recovery rate of gold and silver, high metal value, etc., to achieve the effect of reducing reagent consumption, mild process conditions, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The silver slag of copper anode slime is leached with 20g / L HCl+300g / L NaCl solution, the leaching liquid-solid ratio is 5:1, the leaching time is 3h, the leaching temperature is 95°C, NaClO is added as the oxidant during leaching, and the leaching rate of lead, gold and silver 98%, 99%, and 99%, respectively. Lead leachate and lead slag are obtained by filtration; the leachate is replaced by lead powder for gold and silver, and iron powder for lead to obtain gold and silver concentrate and sponge lead respectively. After the replacement, the liquid is neutralized with CaO In addition to SO 4 2- , Fe 2+ , the neutralization temperature is 90°C, the neutralization time is 4 hours, the end point is pH4.0, oxygen is added as the oxidant during neutralization, the neutralization slag is piled up, and Fe in the liquid after neutralization 总 4 2- <50mg / L, return to leaching of silver slag.

[0032] Use 400g / LNa after washing the lead slag 2 CO 3 Secondary leaching of th...

Embodiment 2

[0034] Use 50g / L HCl+350g / L KCl solution to leach the silver slag from copper anode slime, the leaching liquid-solid ratio is 6:1, the leaching time is 3h, the leaching temperature is 95°C, and NaClO is added during leaching 3 As an oxidizing agent, the leaching rates of lead, gold, and silver are 98%, 99%, and 99% respectively, and lead leachate and lead slag are obtained by filtration; gold and silver concentrates, Sponge lead, after replacement, use CaO+NaOH to neutralize and remove SO 4 2- , Fe 2+ , neutralization temperature 90°C, neutralization time 3h, end point pH 4.0, hydrogen peroxide is added as oxidant during neutralization, neutralization slag is piled up, Fe in the liquid after neutralization 总 4 2- <50mg / L, return to leaching of silver slag.

[0035] Use 380g / LNa after washing the lead slag 2 CO 3 Secondary leaching of the solution, liquid-solid ratio 5:1, leaching temperature 90°C, leaching time 4h, filtering to obtain leaching solution and barium convers...

Embodiment 3

[0037] Use 50g / L HCl+300g / L NaCl solution to leach the silver slag from copper anode slime, the leaching liquid-solid ratio is 4:1, the leaching time is 2h, the leaching temperature is 90°C, and Cl is added during leaching 2 As an oxidizing agent, the leaching rates of lead, gold, and silver are 98%, 99%, and 99% respectively, and lead leachate and lead slag are obtained by filtration; gold and silver concentrates, Sponge lead, the solution after replacement is neutralized with CaO to remove SO 4 2- , Fe 2+ , neutralization temperature 85°C, neutralization time 4h, end point pH 4.5, add NaClO during neutralization 3 As an oxidant, the neutralized slag is piled up, and Fe in the liquid after neutralization 总 4 2- <50mg / L, return to leaching of silver slag.

[0038] Use 350g / LNa after washing the lead slag 2 CO 3 +30g / LNa 2 SO 4 Secondary leaching of the solution, liquid-solid ratio 4:1, leaching temperature 90°C, leaching time 4h, filtering to obtain leaching solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com