Step leaching method for multi-element waste containing lithium

A leaching and waste technology, which is applied in the field of leaching lithium-containing multi-component waste by using lattice defects, can solve problems such as large differences in valence and activity, single crystal structure, lattice defects, etc., to avoid technical problems, high purity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A stepwise leaching method for lithium-containing multiple waste materials, comprising the following steps:

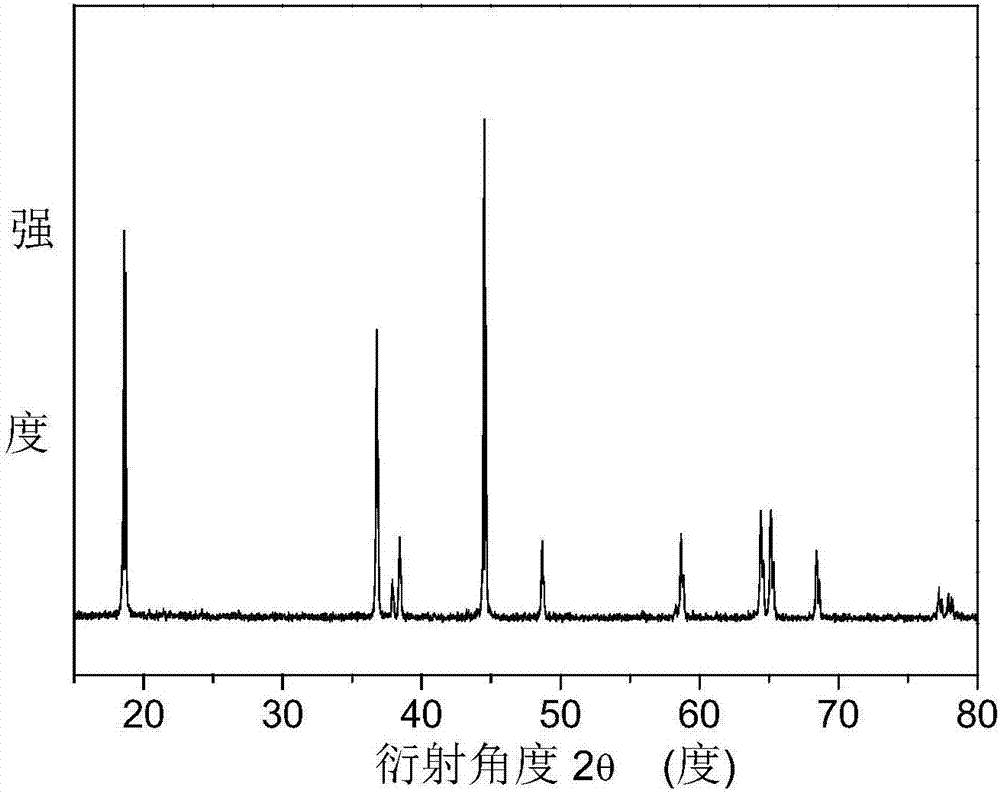

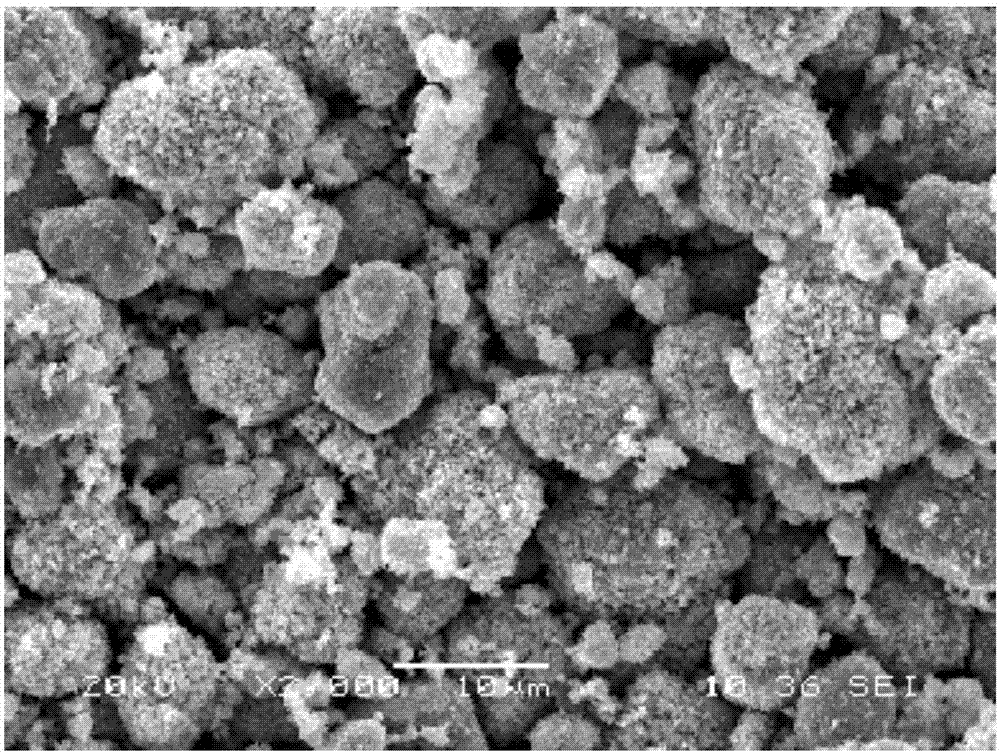

[0051] (1) Weigh Lithium-containing multi-element waste LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 powder 10.0g, figure 1 for LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 XRD pattern of waste powder, figure 2 for LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The SEM picture of the waste powder is shown in figure 2 shown. figure 1 Show LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Powder is ɑ-NaFeO 2 Crystal form, sharp peak shape, that is, the crystal is relatively complete, and there is no impurity peak; figure 2 It is shown that it is a spherical particle with a particle size of about 10-20 μm; the mass fractions of lithium, nickel, cobalt and manganese are 7.20%, 20.3%, 20.3% and 19.0%, respectively, as detected by AAS and ICP. Will LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The waste powder was put into a 500mL single-necked flask. Weigh 18.0 g of oxalic acid crystals to form 200 mL of a 1 mol / L solution, and pour ...

Embodiment 2

[0055] A stepwise leaching method for lithium-containing multiple waste materials, comprising the following steps:

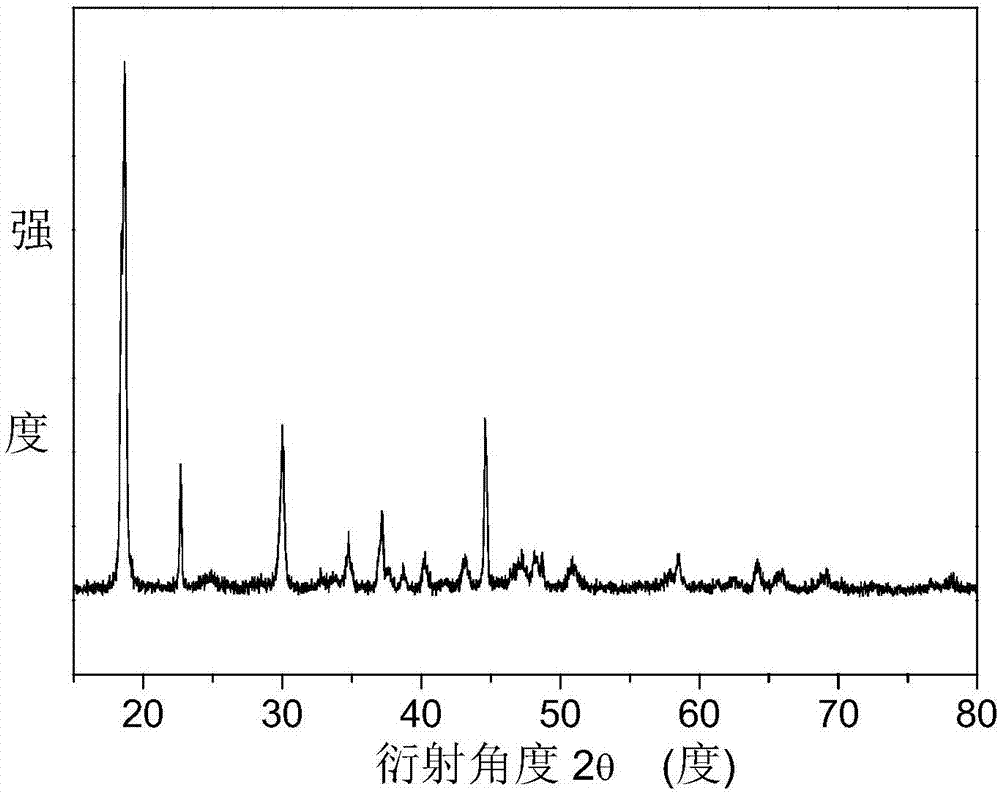

[0056] (1) Weigh Lithium-containing multi-element waste LiNi 0.4 co 0.1 mn 1.5 o 4 Powder 10.0g, LiNi 0.4 co 0.1 mn 1.5 o 4 The XRD pattern of the powder is as follows Figure 7 As shown, LiNi 0.4 co 0.1 mn 1.5 o 4 The SEM picture of the powder is as follows Figure 8 shown. Figure 7 Show LiNi 0.4 co 0.1 mn 1.5 o 4 The powder is in the spinel crystal form with sharp peaks, that is, the crystals are relatively complete and there are no miscellaneous peaks; Figure 8 Show LiNi 0.4 co 0.1 mn 1.5 o 4 The powder is an ellipsoidal particle with a particle size of about 5-10 μm; the mass fractions of lithium, nickel, cobalt and manganese are 3.8%, 12.8%, 3.2% and 45.1%, respectively, as detected by AAS and ICP. Will LiNi 0.4 co 0.1 mn 1.5 o 4 The powder was put into a 500mL single-necked flask. Weigh 18.0 g of oxalic acid crystals to form 40...

Embodiment 3

[0060] A stepwise leaching method for lithium-containing multiple waste materials, comprising the following steps:

[0061] (1) Weigh Lithium-containing multi-element waste LiNi 5 / 10 co 2 / 10 mn 3 / 10 o 2 Powder 10.0g, LiNi 5 / 10 co 2 / 10 mn 3 / 10 o 2 The powder was put into a 500mL single-necked flask. As detected by AAS and ICP, the contents of lithium, nickel, cobalt and manganese are 7.20%, 30.4%, 12.2% and 17.1% respectively. Weigh 18.0 g of oxalic acid crystals to form 400 mL of a 0.5 mol / L solution, and pour the oxalic acid solution into the above-mentioned one-necked flask, that is, the solid-to-liquid ratio is 25 g / L. Put the one-necked flask into a water bath, set the temperature of the water bath to 40°C, stir with a magnet, and continue the reaction for 4 hours. After the reaction was completed, the lithium oxalate leaching solution and the leaching residue A were obtained by suction filtration and separation. Lithium oxalate leaching solution and leaching res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com