A recovery system and recovery method for waste resin powder

A recovery system and recovery method technology, applied in the field of waste resin powder recovery system, can solve the problems of no analysis of material components, no mention of leaching rate, and easy sedimentation of particles, so as to shorten the cultivation cycle, reduce production costs, and eliminate waste. highly harmful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

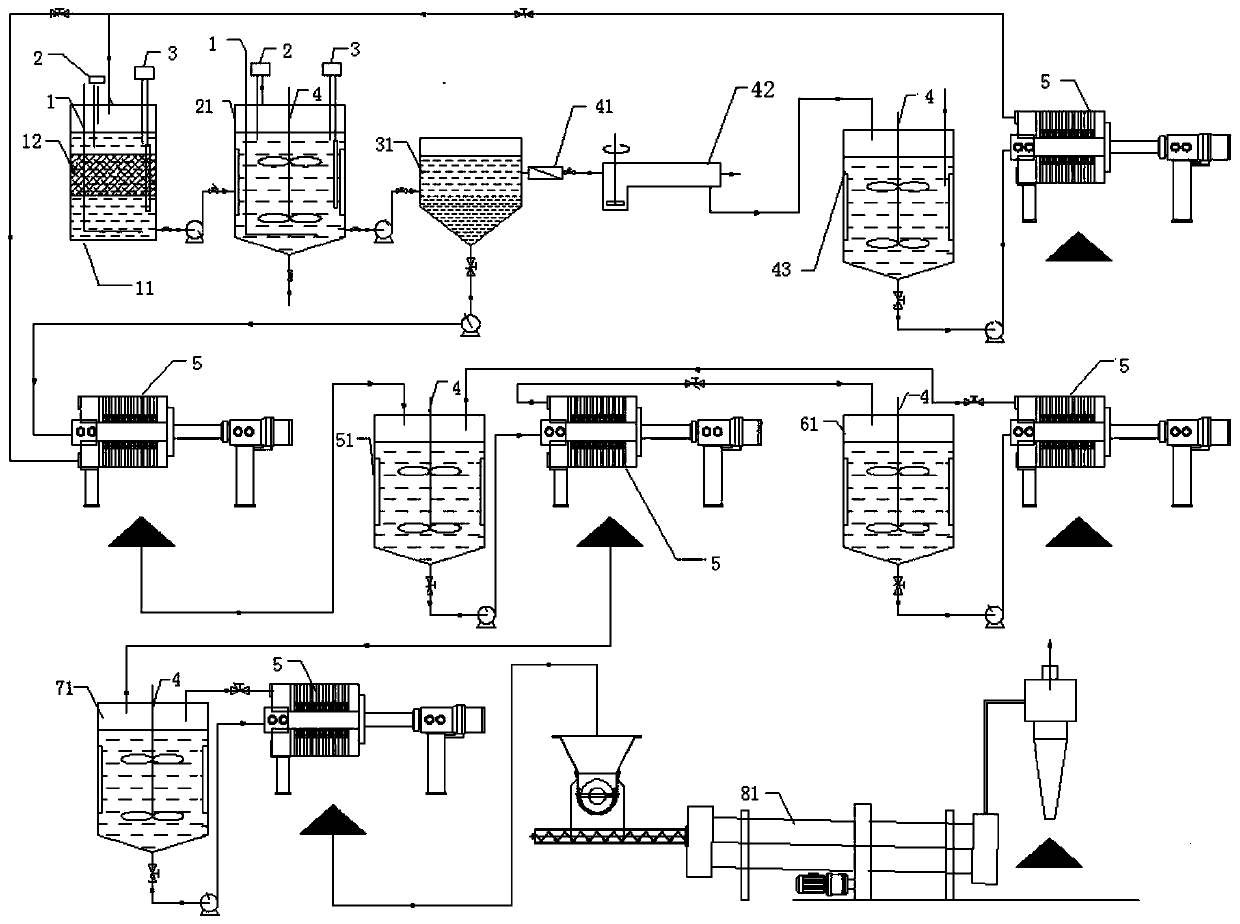

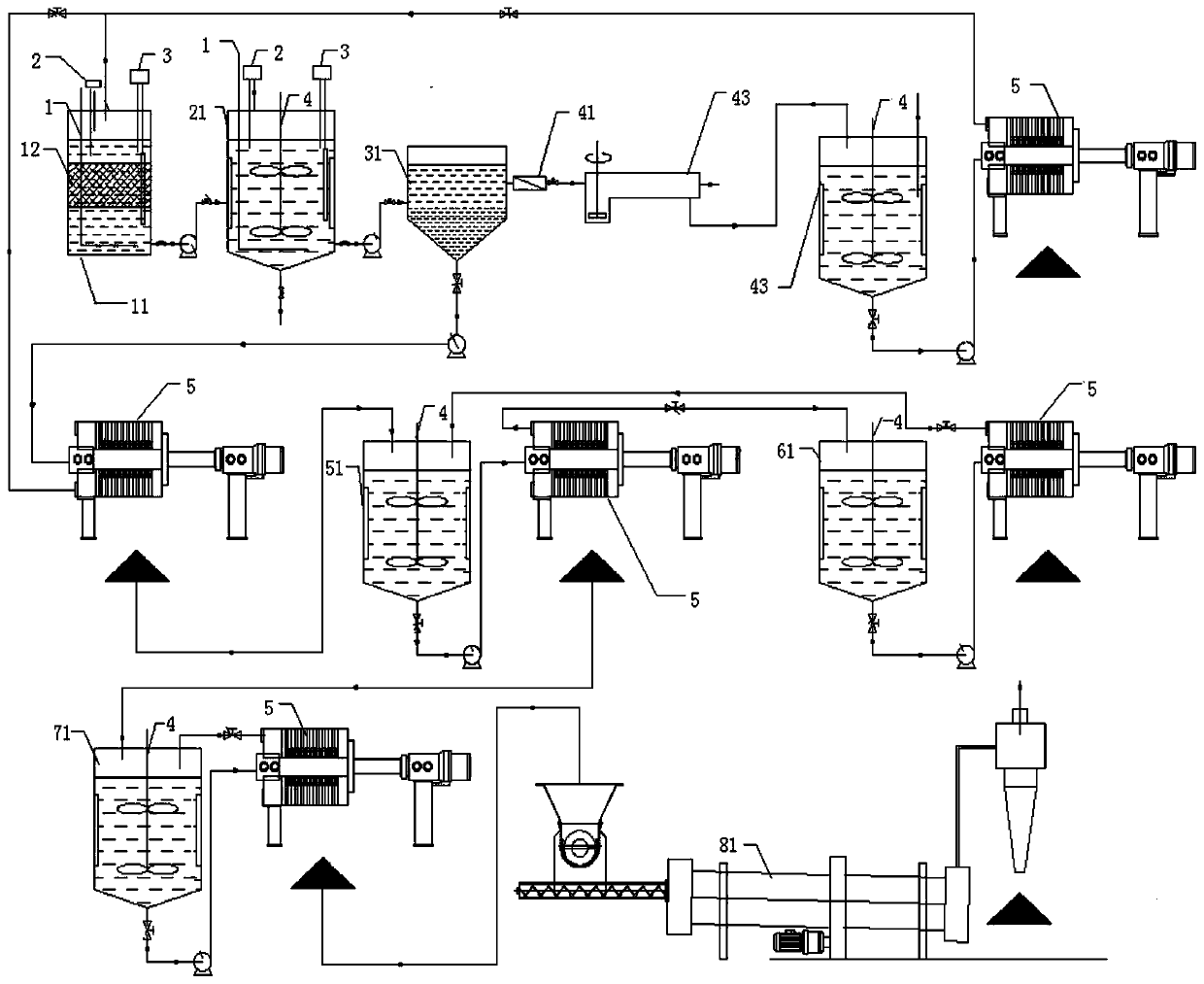

Image

Examples

Embodiment 1

[0050] A. Microbial culture stage:

[0051] Configure basal medium, its composition content: ammonium sulfate 3g / L, magnesium sulfate heptahydrate 0.5g / L, potassium hydrogen phosphate 0.8g / L, potassium chloride 0.12g / L, calcium nitrate 0.05g / L, sulfuric acid heptahydrate Ferrous iron 50g / L, sulfur powder 10g / L, adjust the pH to 2 with sulfuric acid, add the basal medium into the culture tank, and inoculate Thiobacillus ferrooxidans CS 78 (Acidithiobacillus ferrooxidans) into the culture tank according to the inoculum size 10% Incubate at a temperature of 30°C until the cell concentration in the solution reaches 10 8 cells / mL, add grid packing, hang film culture, and gradually start continuous mixing culture to obtain a bacterial concentration of 1.31×10 8 Each / mL microbial culture solution, the oxidation-reduction potential of the culture solution is 709mV, and the specific parameters are shown in Table 1.

[0052] B. Leaching stage:

[0053] Import the microbial culture so...

Embodiment 2

[0074] A. Microbial culture stage:

[0075] Configure the basic medium, its composition content: ammonium sulfate 1.5g / L, magnesium sulfate heptahydrate 0.25g / L, potassium hydrogen phosphate 0.5g / L, potassium chloride 0.1g / L, calcium nitrate 0.01g / L, heptahydrate Ferrous sulfate 30g / L, adjust pH to 1.5 with sulfuric acid, add basal medium in the culture tank, and by inoculum size 10%, add Thiobacillus ferrooxidans CS 78 (Acidithiobacillus ferrooxidans), acidophilus ferrooxidans Leptospira The mixed strains of CS13 (Leptospirillum ferriphilum) and acidophilic sulfur bacillus CS17 (Sulfobacillus thermosulfidooxidans) were inoculated into the culture tank and cultivated at a temperature of 45°C until the cell concentration in the solution reached 108 cells / mL, add grid film-hanging filler, hang film culture, gradually start continuous mixing culture, and obtain a bacterial concentration of 1×10 9 Individual / mL microbial culture fluid, the oxidation-reduction potential of the cult...

Embodiment 3

[0092] A. Microbial culture stage:

[0093] Configure basal medium, its composition content: ammonium sulfate 2g / L, magnesium sulfate heptahydrate 0.3g / L, potassium hydrogen phosphate 0.6g / L, potassium chloride 0.1g / L, calcium nitrate 0.03g / L, sulfuric acid heptahydrate Ferrous iron 40g / L, sulfur powder 0.2g / L, adjust pH to 2.0 with sulfuric acid, base culture medium is added in the culture tank, and acidophilic sulfur bacillus ferrivorans CS12 (Acidithiobacillus ferrivorans) and acidophilic iron Thiobacillus ferrooxidans CS 78 (Acidithiobacillus ferrooxidans) was inoculated into the culture tank and cultured at a temperature of 30°C until the cell concentration in the solution reached 10 8 each / mL, add the screen-packed waste resin module film-hanging filler, film-hanging culture, and gradually start continuous cultivation, and obtain a bacterial concentration of 1.5×10 8 Individual / mL microbial culture fluid, the oxidation-reduction potential of the culture fluid is 706mV. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com