A kind of method for reclaiming rhenium in rhenium concentrate

A concentrate and leaching technology, which is applied in the field of rhenium recovery in rhenium concentrate, can solve the problems of low leaching rate, long cycle, high safety requirements, etc., and achieve the effect of improving recovery rate and effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

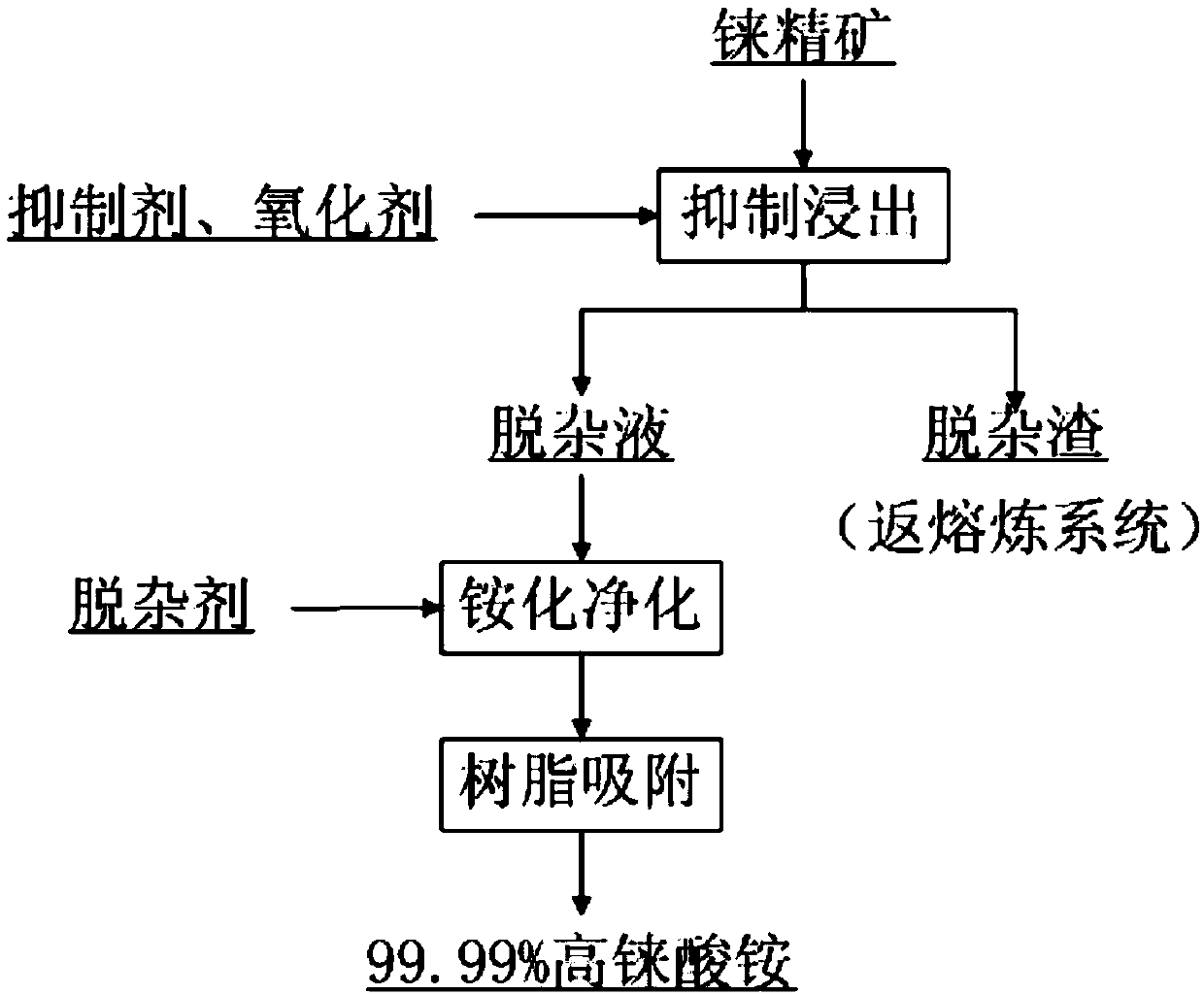

Method used

Image

Examples

Embodiment 1

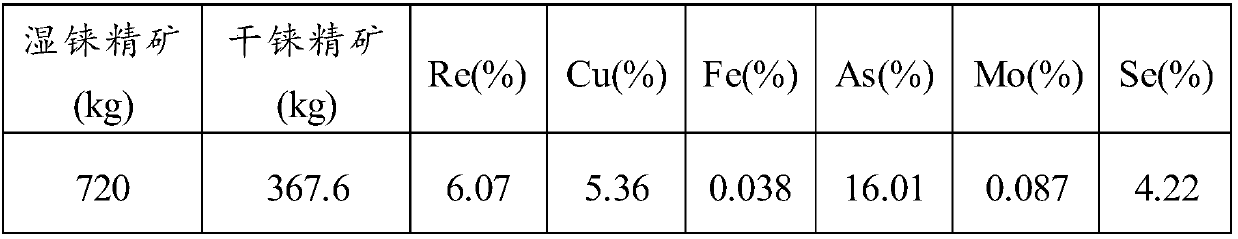

[0033] Firstly, the rhenium concentrate is mixed with water according to the solid-to-liquid ratio of 1:4, and the rhenium concentrate is low in copper and high in arsenic. The composition of the rhenium concentrate is shown in Table 1:

[0034] Table 1 Composition and material quantity data table of rhenium concentrate

[0035]

[0036] Add 300kg of quicklime to adjust the pH to 14, then add 2099kg of hydrogen peroxide, the amount of hydrogen peroxide added is 5.71 times the dry weight, and then add 72kg of quicklime to adjust the pH to 14 to obtain the decontamination residue and decontamination solution. The ingredients are shown in Table 2 and Table 3:

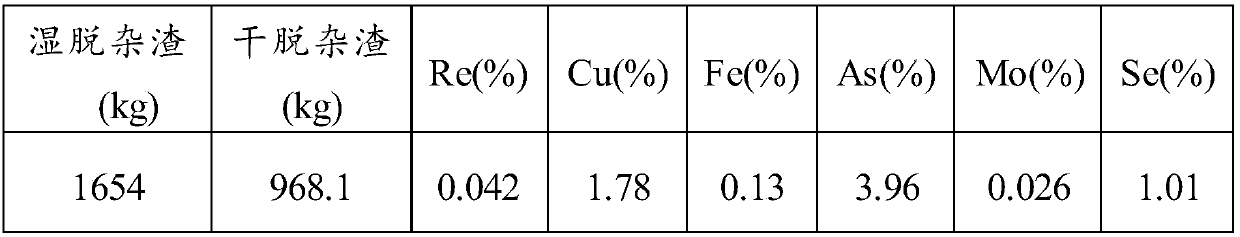

[0037] Table 2 Composition and slag amount data table of de-impurity slag

[0038]

[0039] Table 3 Composition data table of impurity removal solution (g / L)

[0040] Re

Cu

Fe

As

Mo

Se

8.75

0.0040

0.00080

0.032

0.026

0.74

[0041] It can be seen from Table 2 a...

Embodiment 2

[0044]Firstly, the rhenium concentrate is mixed with water according to the solid-to-liquid ratio of 1:3, and the rhenium concentrate is low in copper and high in arsenic, and the amount of material is reduced. The composition of the rhenium concentrate is shown in Table 4:

[0045] Table 4 Composition and material quantity data table of rhenium concentrate

[0046]

[0047] Add 223kg of quicklime to adjust the pH to 14, then add 1356kg of hydrogen peroxide, the amount of hydrogen peroxide added is 5.50 times the dry weight, and then add 50kg of quicklime to adjust the pH to 14 to obtain the decontamination residue and decontamination solution. The ingredients are shown in Table 5 and Table 6:

[0048] Table 5 Composition and slag amount data table of de-impurity slag

[0049]

[0050] Table 6 Composition data table (g / L) of the impurity removal solution

[0051] Re

Cu

Fe

As

Mo

Se

9.44

0.0026

<0.00050

0.0058

0.022

0.09...

Embodiment 3

[0055] Firstly, the rhenium concentrate is mixed with water according to the solid-to-liquid ratio of 1:5, and the rhenium concentrate is high in copper and low in arsenic. The composition of the rhenium concentrate is shown in Table 7:

[0056] Table 7 Composition and material data table of rhenium concentrate

[0057]

[0058]

[0059] Add 297kg of quicklime to adjust the pH to 14, then add 2130kg of hydrogen peroxide, the amount of hydrogen peroxide added is 5.92 times the dry weight, and then add 70kg of quicklime to adjust the pH to 14 to obtain the decontamination slag and decontamination solution. The ingredients are shown in Table 8 and Table 9:

[0060] Table 8 Composition and slag amount data table of de-impurity slag

[0061]

[0062] Table 9 Composition data sheet (g / L) of the impurity removal solution

[0063] Re

Cu

Fe

As

Mo

Se

5.82

0.0046

<0.00050

0.0073

0.021

0.48

[0064] It can be seen from Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com