A kind of manganese-doped bismuth magnesium titanate-lead titanate piezoelectric single crystal and preparation method thereof

A lead titanate piezoelectric, bismuth titanate technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of difficult preparation, dielectric loss and large leakage current, and achieve single crystal Uniform composition, reduced leakage current and dielectric loss, and improved piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

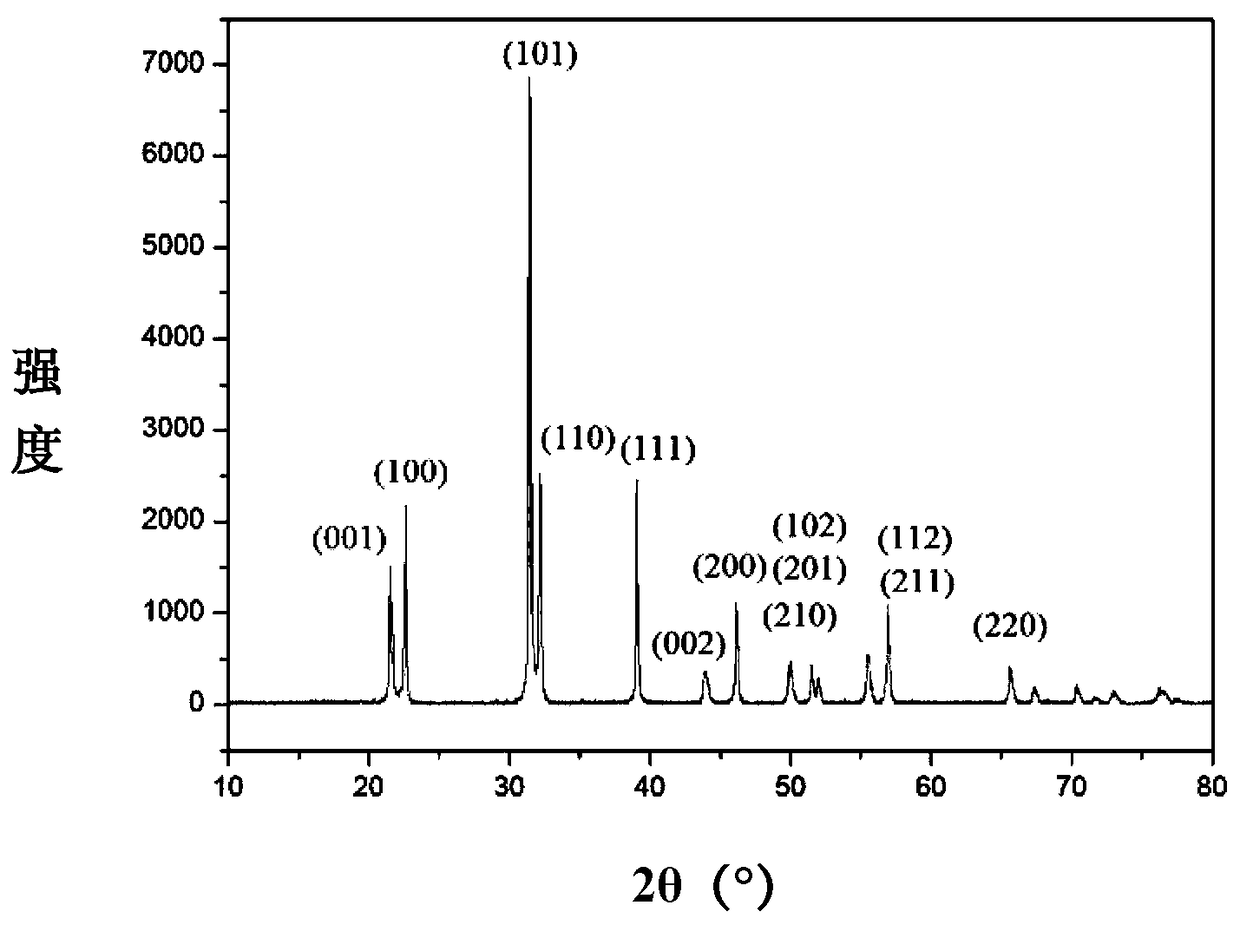

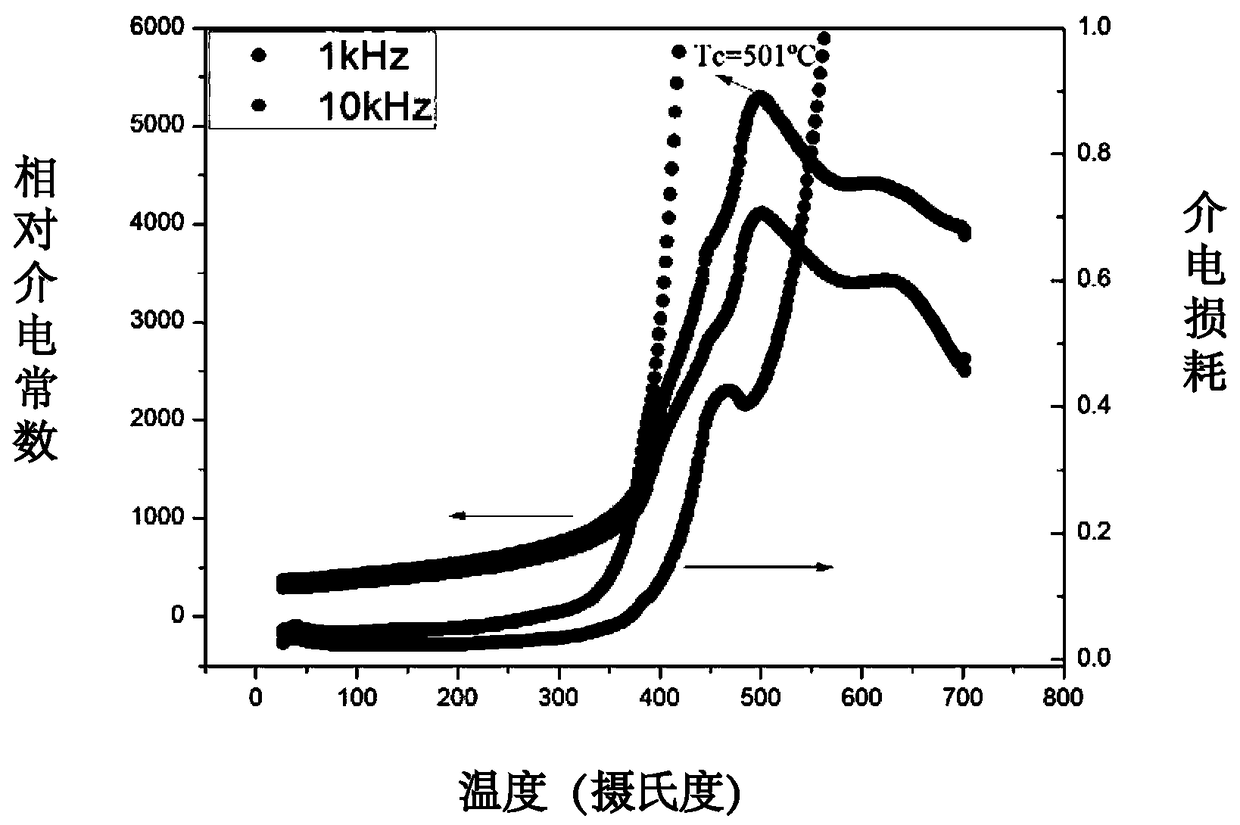

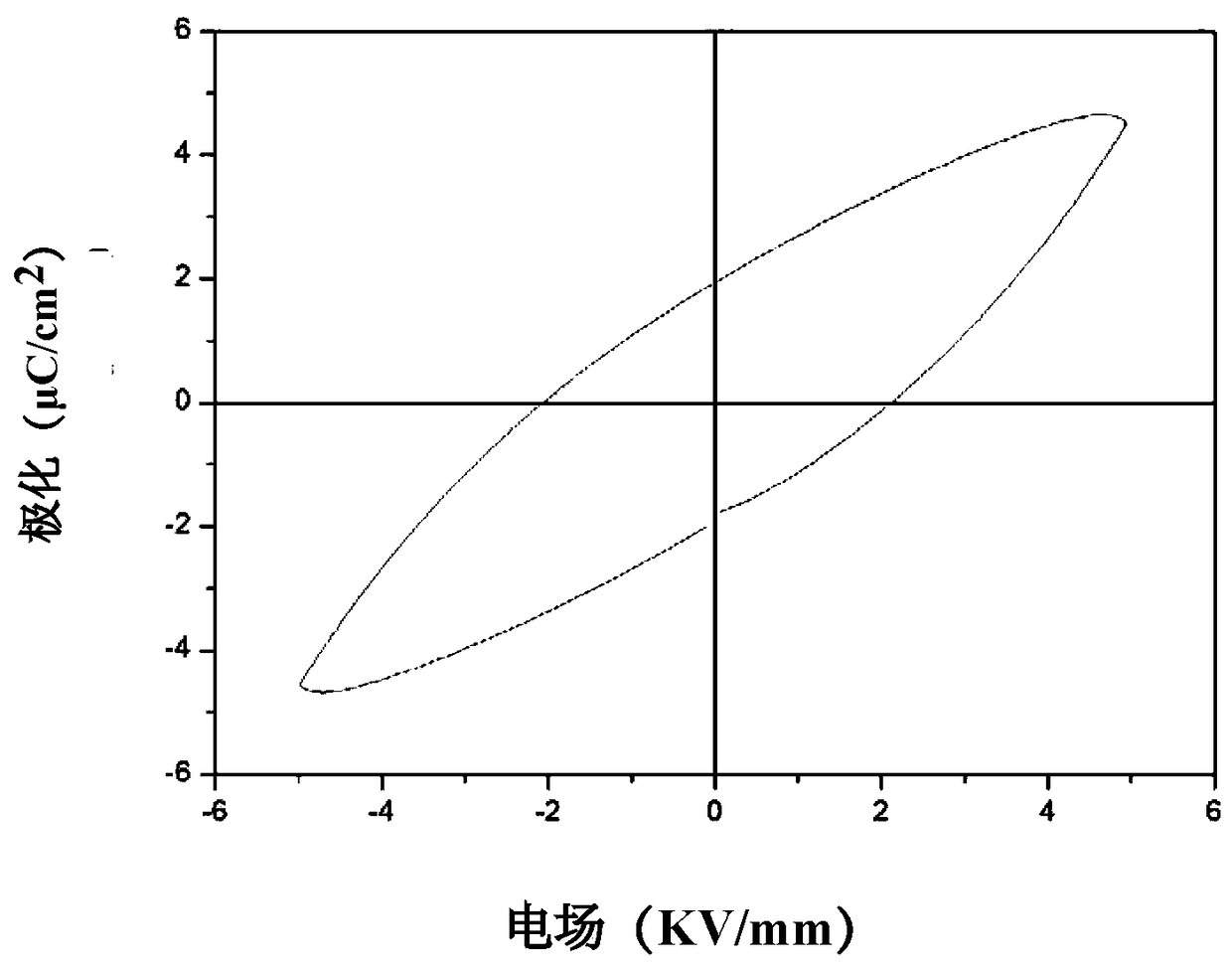

Embodiment 1

[0032] The initial raw material Pb 3 o 4 , MgO, TiO 2 、 Bi 2 o 3 , MnO 2 According to the chemical formula 0.76Bi(Mg 1 / 2 Ti 1 / 2 )O 3 -0.24PbTiO 3 +0.1mol%MnO 2The metering ratio weighs, mixes and grinds. The uniformly mixed raw materials were put into a platinum crucible, and the platinum crucible was placed in a muffle furnace and pre-fired at a temperature of 850°C for 4 hours to obtain a pre-fired powder. The calcined powder is subjected to secondary grinding. Then take by weighing the calcined powder quality after secondary grinding and be 30% Pb 3 o 4 、 Bi 2 o 3 and B 2 o 3 (Pb 3 o 4 : Bi 2 o 3 =7:3) as a flux, mixed evenly with the calcined powder after secondary grinding, then put the mixed powder into a platinum crucible, and place the platinum crucible in the muffle furnace, and the The temperature rises from room temperature to 1180°C over 7 hours, and keeps the temperature constant for 10 hours to fully melt the raw materials, then the temperatu...

Embodiment 2

[0039] The initial raw material Pb 3 o 4 , MgO, TiO 2 、 Bi 2 o 3 , MnO 2 According to the chemical formula 0.76Bi(Mg 1 / 2 Ti 1 / 2 )O 3 -0.24PbTiO 3 +0.1mol%MnO 2 The metering ratio weighs, and then weighs the Pb that accounts for 30% of the raw material mass 3 o 4 、 Bi 2 o 3 and B 2 o 3 (Pb 3 o 4 : Bi 2 o 3 =7:3) as a flux, mixed and ground evenly. Then put the mixed powder into the platinum crucible, and place the platinum crucible in the muffle furnace. The temperature in the muffle furnace rises from room temperature to 1180°C over 7 hours, and keeps the temperature constant for 10 hours to fully melt the raw materials, and then muffle The temperature in the furnace drops to 1000°C at a rate of 2°C / h, then to 800°C at a rate of 5°C / h, then to 700°C at a rate of 20°C / h, and then to 60°C / h. to 200°C, and finally cooled to room temperature naturally with the furnace. At room temperature, the manganese-doped bismuth titanate-lead titanate piezoelectric single...

Embodiment 3

[0042] The initial raw material Pb 3 o 4 , MgO, TiO 2 、 Bi 2 o 3 , MnO 2 According to the chemical formula 0.76Bi(Mg 1 / 2 Ti 1 / 2 )O 3 -0.24PbTiO 3 +0.5mol%MnO 2 The metering ratio weighs, mixes and grinds. The uniformly mixed raw materials were put into a platinum crucible, and the platinum crucible was placed in a muffle furnace and pre-fired at a temperature of 850°C for 4 hours to obtain a pre-fired powder. The calcined powder is subjected to secondary grinding. Then take by weighing the calcined powder quality after secondary grinding and be 30% Pb 3 o 4 、 Bi 2 o 3 As a flux (Pb 3 o 4 : Bi 2 o 3 =7:3), mixed evenly with the calcined powder after the secondary grinding, then put the mixed powder into the platinum crucible, and put the platinum crucible in the muffle furnace, the temperature in the muffle furnace was changed from room temperature to After 7 hours, it was raised to 1180°C, and the temperature was kept constant for 10 hours to fully melt the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com