A preparation and application method of PCBS-contaminated soil in-situ remediation agent based on waste biomass

A technology of waste biomass and in-situ remediation agent, which is applied in the field of high value-added resource utilization of waste biomass, can solve the problems of lack, low cost, and low biodegradation efficiency, so as to save production costs, reduce environmental pollution, and use simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

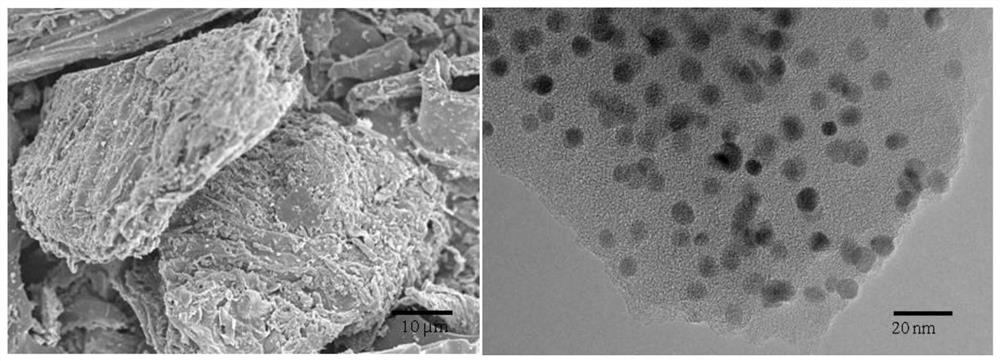

Image

Examples

Embodiment 1

[0024] 1. Preparation of raw materials

[0025] The corn stalks were crushed to less than 5mm and used for later use; the PCBs-contaminated soil was taken from the storage point of discarded capacitors. The soil samples were dried in a fume hood for 24 hours, and then the leaves, plant roots, and stones were removed, and then crushed and passed through a 120-mesh sieve. The samples were stored away from light in aluminum foil sample bags (the chlorine content in the soil was 8.26%, and all of them existed in the form of organic chlorine).

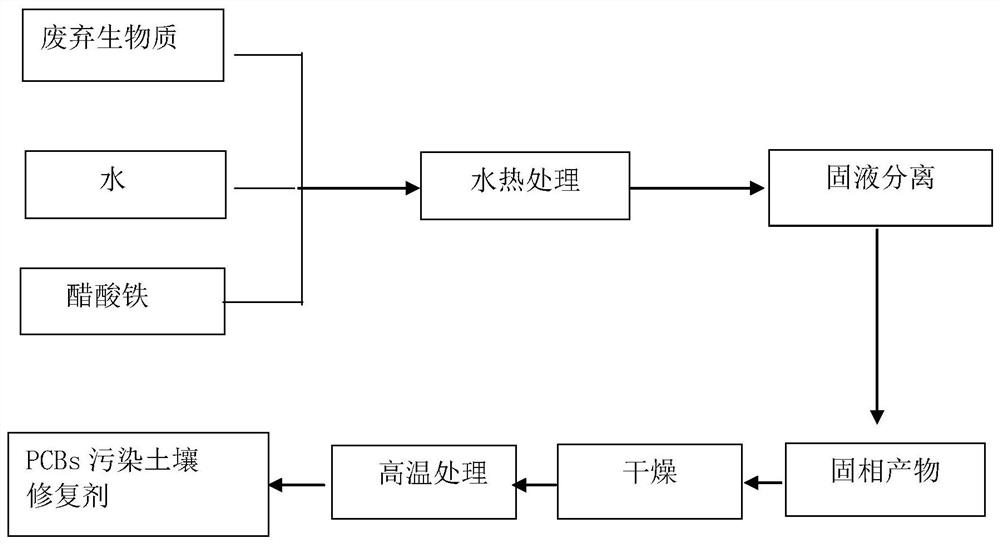

[0026] 2. Preparation of restoration agent

[0027] 1) Mix the crushed straw with iron acetate, add water and stir evenly to prepare a mixed material, wherein straw (dry basis): iron acetate is mixed in a mass ratio of 5:1; the ratio of straw (dry basis) to water mass 1:5.

[0028] 2) Add the mixed materials into the hydrothermal reaction kettle and heat the reaction kettle to 200° C., and conduct hydrothermal treatment for 60 minutes.

...

Embodiment 2

[0043] In addition to using rice straw as biomass as raw material;

[0044] In the repairing agent preparation process, in addition to step 1), rice stalk (dry basis): the ratio of the mass of iron acetate is 5:1, and the ratio of rice stalk (dry basis) to water is mixed in a ratio of 1:5; step 2) Heating the reactor to 200°C for 80 minutes; Step 4) Performing thermochemical treatment at 700°C for 60 minutes, the rest is the same as in Example 1. The dechlorination effect of PCBs in soil is shown in Table 1.

Embodiment 3

[0046] In addition to using pig manure as biomass as raw material;

[0047] In the repairing agent preparation process, in addition to step 1), pig manure (dry basis): the ratio of the mass of iron acetate is 5:2, and the ratio of pig manure (dry basis) to water is 1:5; the step 2) Heating the reactor to 220° C. for 60 minutes; step 4) performing heat treatment at 600° C. for 60 minutes, the rest is the same as in Example 1.

[0048] The dechlorination effect of PCBs in soil is shown in Table 1.

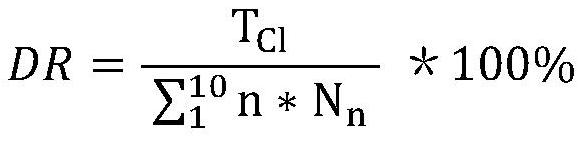

[0049] Table 1. Dechlorination effect of PCBs in contaminated soil.

[0050]

[0051] It can be seen from Table 1 that the restoration agent prepared by the present invention can realize rapid and efficient in-situ degradation and dechlorination of PCBs after being added to PCBs-contaminated soil. After 60 days, the dechlorination rate of PCBs is as high as 57%, and the restoration The agent is prepared from waste biomass, so it has the characteristics of green, environmental pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com