Flame-retardant inorganic compound EPS (Expanded Polystyrene) insulation board and preparation method thereof

An inorganic composite, flame retardant technology, applied in the field of thermal insulation materials, can solve problems such as unoptimistic stability, flame retardant performance defects, inability to achieve Class A non-combustibility, etc., and achieves good market potential, low cost, and excellent thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The second aspect of the present invention provides a method for preparing the flame-retardant inorganic composite EPS insulation board described in the first aspect of the present invention, comprising the following steps:

[0021] (1) adding a foaming agent to the expandable polystyrene particles, pre-foaming, and curing;

[0022] (2) Add inorganic gelling material, inorganic filler, graphite, ammonium polyphosphate, zinc borate, cellulose ether, organosilicon water-repellent, rubber powder to the ripened pre-expanded polystyrene, fully stir;

[0023] (3) pouring the mixed material in the step (2) into a forming mold, and using steam heating for compression molding, then demoulding, curing, and cutting to obtain the flame-retardant inorganic composite EPS insulation board.

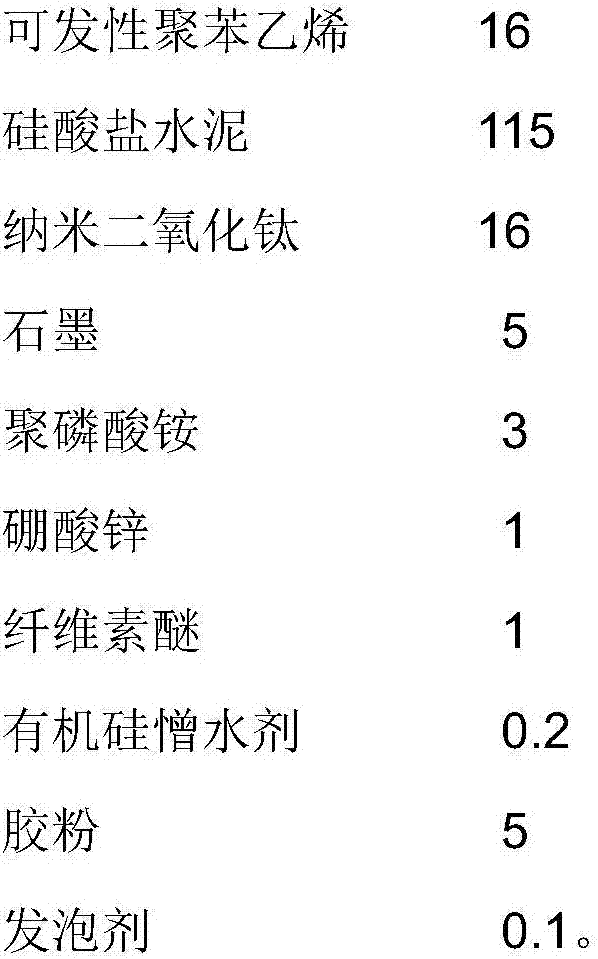

Embodiment 1

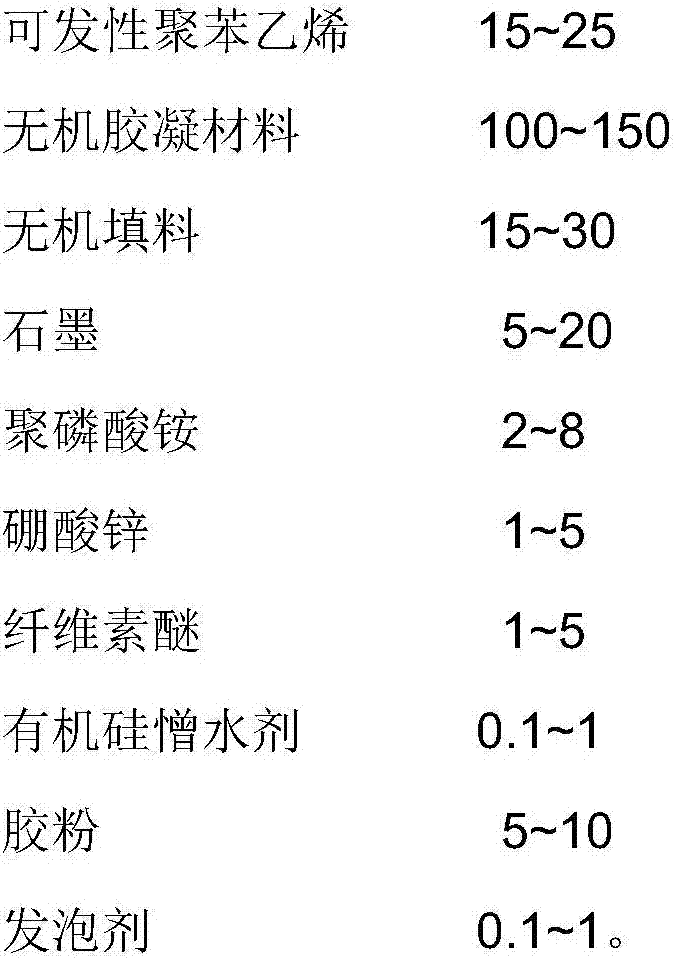

[0026] A flame-retardant inorganic composite EPS insulation board, comprising the following components in proportion by weight:

[0027]

[0028] Its preparation steps include:

[0029] (1) adding a foaming agent to the expandable polystyrene particles, pre-foaming, and curing;

[0030] (2) Add Portland cement, nano-titanium dioxide, graphite, ammonium polyphosphate, zinc borate, cellulose ether, organic silicon water-repellent, rubber powder to the matured pre-expanded polystyrene, fully stir;

[0031] (3) pouring the mixed material in the step (2) into a forming mold, and using steam heating for compression molding, then demoulding, curing, and cutting to obtain the flame-retardant inorganic composite EPS insulation board.

Embodiment 2

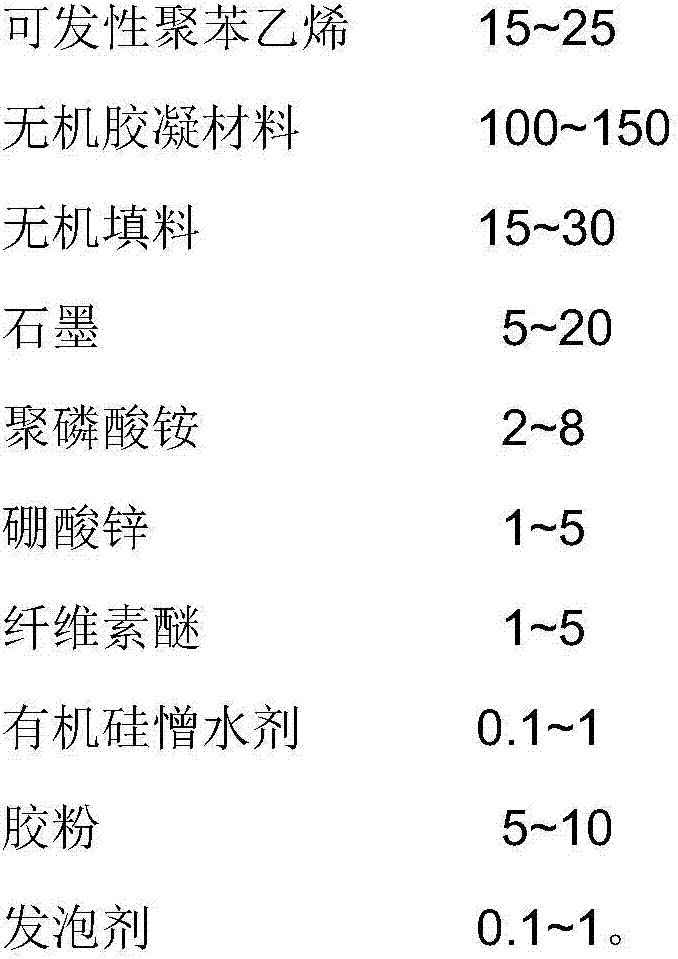

[0033] A flame-retardant inorganic composite EPS insulation board, comprising the following components in proportion by weight:

[0034]

[0035]

[0036] Its preparation steps include:

[0037] (1) adding a foaming agent to the expandable polystyrene particles, pre-foaming, and curing;

[0038] (2) Add Portland cement, volcanic ash, graphite, ammonium polyphosphate, zinc borate, cellulose ether, organic silicon water-repellent, rubber powder to the matured pre-expanded polystyrene, fully stir;

[0039] (3) pouring the mixed material in the step (2) into a forming mold, and using steam heating for compression molding, then demoulding, curing, and cutting to obtain the flame-retardant inorganic composite EPS insulation board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com