Anode material for non-aqueous electrolyte secondary battery, and preparation method and application thereof

A non-aqueous electrolyte, secondary battery technology, applied in the intersection of nanomaterials and new energy technology, can solve problems such as volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Embodiment 1 Preparation of silicon oxide one-dimensional nanomaterial

[0089] Get 10.0g cetyltrimethylammonium bromide (CTAB) and 11.2g solid Na 2 SiO 3 9H 2 O, dissolved in 175 mL of deionized water with stirring and sonication to form a homogeneous solution. Then 175 mL of ethyl acetate was added to the solution, and the mixture was left standing at room temperature for 5 hours, and then heated by a 90° C. water bath for 50 hours. After carrying out the above hydrothermal synthesis reaction in a polytetrafluoroethylene reactor with a polytetrafluoroethylene liner, FeCl 3 Solution treatment, and through centrifugation, and 70 ℃ baked to dryness, dried 4 hours at 400 ℃, obtained solid product double mesoporous silica pellet; Gained silica pellet was placed in ethylenediamine solution ( The volume ratio of diamine and deionized water is 2:1) and heated in steam (200°C) for 30 hours, then use 1mol / L hydrochloric acid solution to remove the iron element in the soluti...

Embodiment 2

[0090] Embodiment 2 Preparation of one-dimensional silicon oxide / carbon composite material

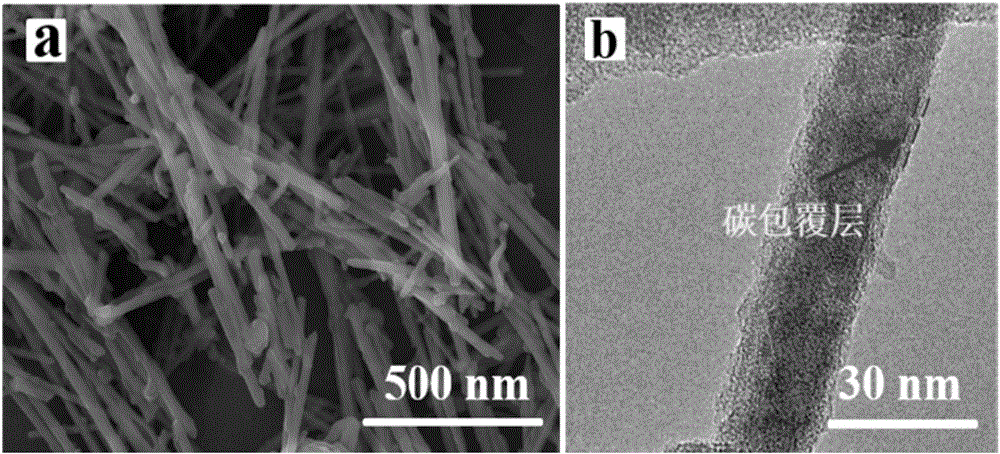

[0091] Get the SiO prepared by Example 1 x 0.1 g of nanowires was dispersed in 10 mL of deionized water, and then mixed with 0.35 g of CTAB. After 30 minutes of ultrasonication and 30 minutes of stirring, 0.5 g of resorcinol, 45.5 mL of pure ethanol and 0.15 mL of ammonia were added to the mixed solution in sequence, and Stir at 35°C for 30 minutes. After that, 0.08 mL of formalin was added to the mixed solution, and stirred overnight. The resulting sample was centrifuged and washed with deionized water and pure ethanol to obtain SiO coated with resorcinol-formaldehyde (RF) resin. x Nanowire core-shell nanostructure, the core-shell structure product is carbonized in an argon atmosphere at 600°C for 5 hours to prepare one-dimensional SiO x / carbon composite. The SEM and TEM characterization results of the composite material are as follows: figure 2 As shown, the thickness of the ...

Embodiment 3

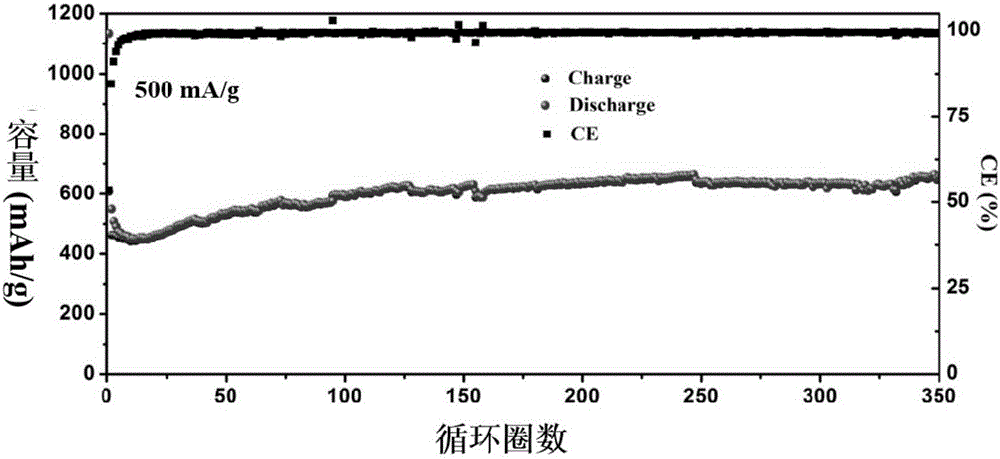

[0093] Weigh 1 g of PVDF, add to NMP solution to dissolve, and stir at high speed for 2 hours to prepare a mixed solution. Take 8.0 g of one-dimensional silicon oxide nanomaterials (prepared in Example 1) and 1.0 g of carbon black, add them to the above solution, and stir at high speed for 1 hour. The uniformly dispersed slurry obtained is coated on a copper foil, dried at 70° C., and rolled with a pair of rollers to obtain a usable electrode. The above-prepared pole piece, diaphragm, lithium sheet, and stainless steel gasket were stacked in sequence, and 200 μL of electrolyte was added and then sealed to form a 2016-style lithium-ion button battery. The capacity and discharge efficiency were tested on the small charge and discharge equipment (LAND CT2001A) of Wuhan Landian Electronics Co., Ltd.

[0094] In the above electrode, the loading amount of the active material is 1.0-1.2 mg / cm 2 , The voltage test window is 0.01-3V. At a current density of 100mA / g, the first discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com