Printing ink for offset lithography and preparation method thereof

A technology of offset printing ink and flat plate, applied in ink, household utensils, applications, etc., can solve the problems of light printing color, pigment dispersion defects, and affecting printing uniformity, and achieve good dispersion, fast drying speed, safety and non-toxicity cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

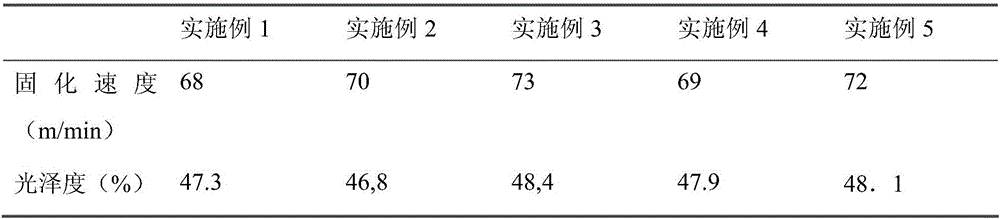

Examples

Embodiment 1

[0020] A flat offset printing ink, which is prepared from the following components in parts by weight: 30 parts of polyurethane, 20 parts of novolac epoxy acrylate, 4 parts of epoxy oil propionate, 5 parts of drier, 17 parts of pigment, 1 part of coupling agent, 0.6 part of antioxidant, 1.5 parts of dispersant and 6 parts of graphene.

[0021] In this embodiment, the graphene is at least one of spherical, flake, tubular, fibrous, helical, and three-dimensional, and its particle size ranges from 0.005 microns to 10000 microns. The novolac epoxy acrylate is bisphenol A modified novolak epoxy acrylate. The polyurethane is an epoxy-modified water-based polyurethane hybrid emulsion. The coupling agent is a silane coupling agent or an aluminate coupling agent. The antioxidant is nanometer copper / PTFE composite material. The drier is a mixed crystal or solid solution of the reaction product of ligand 3,7-diazabicyclo[3.3.1]nonane and metal chloride. Described dispersant is disper...

Embodiment 2

[0024] A flat offset printing ink, prepared from the following components by weight: 25 parts of polyurethane, 10 parts of phenolic epoxy acrylate, 6 parts of epoxy oil propionate, 4 parts of drier, 15 parts of pigment, 3 parts of coupling agent, 0.45 parts of antioxidant, 1 part of dispersant and 8 parts of graphene.

[0025] Further, it is prepared from the following components by weight: 20-30 parts of polyurethane, 20-25 parts of novolac epoxy acrylate, 5 parts of epoxy propionate, 4 parts of drier, 15-25 parts of pigment 20 parts, 2-3 parts of coupling agent, 0.3-0.6 parts of antioxidant, 1-2 parts of dispersant and 7 parts of graphene.

[0026] In this embodiment, the graphene is at least one of spherical, flake, tubular, fibrous, helical, and three-dimensional, and its particle size ranges from 0.005 microns to 10,000 microns. The novolac epoxy acrylate is bisphenol A modified novolak epoxy acrylate. The polyurethane is an epoxy-modified water-based polyurethane hybri...

Embodiment 3

[0029] A flat offset printing ink, which is prepared from the following components in parts by weight: 20 parts of polyurethane, 30 parts of novolac epoxy acrylate, 5 parts of epoxy oil propionate, 3 parts of drier, 20 parts of pigment, 2 parts of coupling agent, 0.3 parts of antioxidant, 2 parts of dispersant and 7 parts of graphene.

[0030] In this embodiment, the graphene is at least one of spherical, flake, tubular, fibrous, helical, and three-dimensional, and its particle size ranges from 0.005 microns to 10000 microns. The novolac epoxy acrylate is bisphenol A modified novolak epoxy acrylate. The polyurethane is an epoxy-modified water-based polyurethane hybrid emulsion. The coupling agent is a silane coupling agent or an aluminate coupling agent. The antioxidant is nanometer copper / PTFE composite material. The drier is a mixed crystal or solid solution of the reaction product of ligand 3,7-diazabicyclo[3.3.1]nonane and metal chloride. Described dispersant is dispersa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com