Preparation method of graphene photo-thermal transformation material for sea water desalination and clean water treatment

A light-to-heat conversion and water purification treatment technology, which is applied in seawater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as equipment corrosion, low energy utilization rate, and low evaporation efficiency, and achieve repeatable Use cleaning, simple structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation methods of intrinsic graphene or graphene derivatives include but are not limited to the following three methods: namely, graphene powder or liquid phase dispersion prepared by expansion and exfoliation of graphite as raw material, gaseous carbon source as raw material through chemical Graphene powder or liquid phase dispersion formed by pulverizing or dispersing graphene prepared by vapor deposition (CVD) or physical vapor deposition (PVD), or graphene-like two-dimensional sheet material formed by chemical polymerization of small molecular substances Agglomerated powder or liquid dispersion.

[0029] Polymers with a chain molecular structure include but are not limited to the following substances: sucrose, cellulose and its derivatives, thermoplastic and thermosetting resin materials (such as: polyvinyl alcohol, polyethylene, polypropylene, epoxy resin, phenolic resin, Aldehyde and ketone resin, etc.); the solvent used is selected from a corresponding g...

Embodiment 1

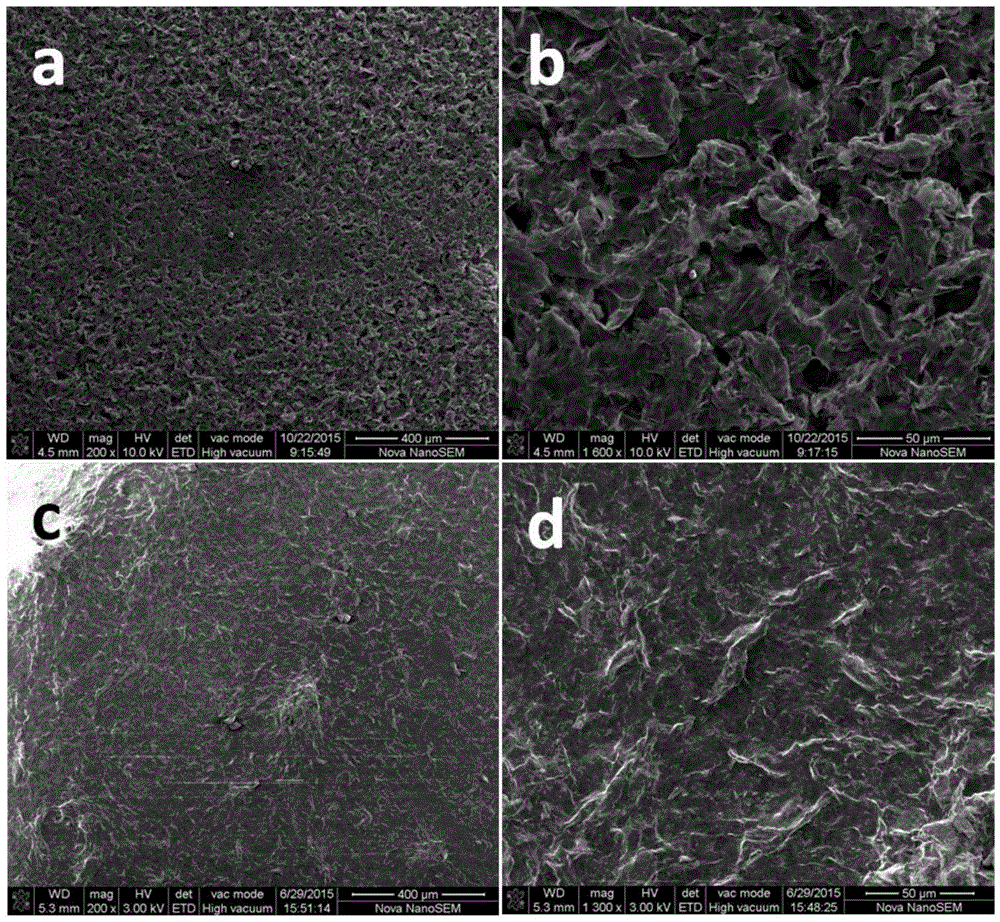

[0033] After 50g graphene powder and 15g polyvinyl alcohol and 1kg water are mixed, utilize high-speed shear emulsification to make it uniform slurry, carry out high-speed centrifugation to above-mentioned slurry, collect lower floor slurry, its solid content (weight ratio) is 8.7%; the above slurry poured into the bottom area is 225cm 2 (15cm×15cm) in a square stainless steel mold to make it flat to form a cake with a thickness of about 2cm; put the cake together with the mold at room temperature for 12 hours and then put it into a blast drying oven and heat it to 80°C for drying for 4 Take it out after one hour, put it into a muffle furnace and heat it to 550° C. for 5 hours to completely carbonize the polyvinyl alcohol in the material. After cooling to room temperature, the black foamy material in the mold is taken out to obtain a graphene foam material with good mechanical strength. Prepare polyvinyl alcohol into a uniform aqueous solution with a concentration of 5wt%, an...

Embodiment 2

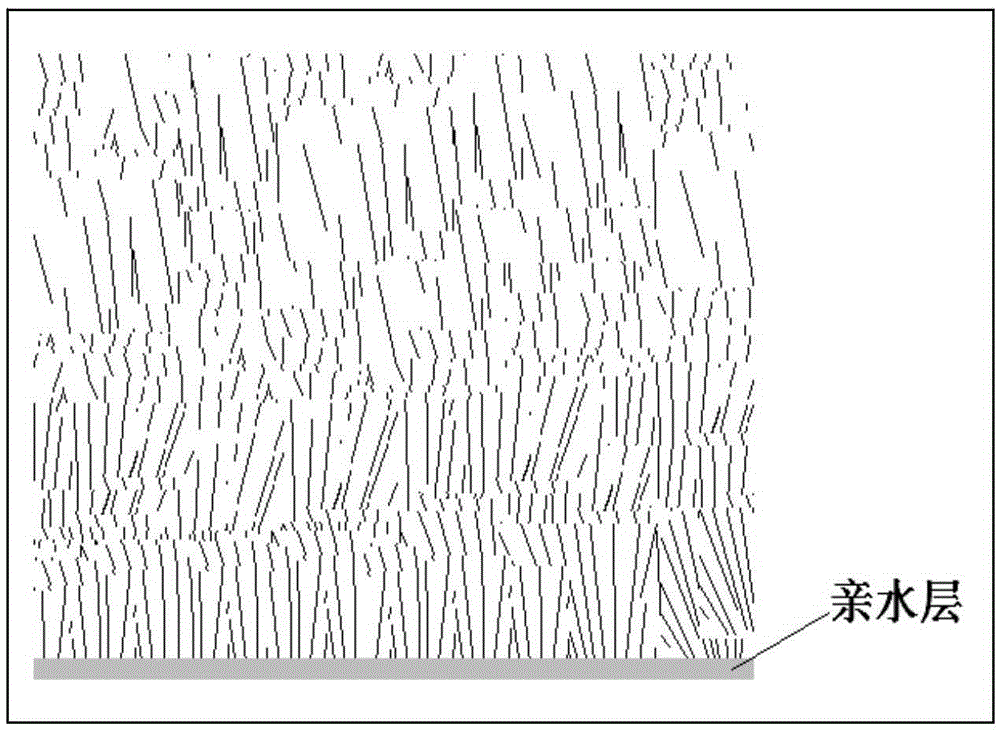

[0036] After 20g graphene powder and 10g hydroxyethyl cellulose and 800g ethanol are mixed, utilize high-speed shear emulsification to make it uniform slurry, above-mentioned slurry is carried out high-speed centrifugation, collect lower floor slurry, its solid content (weight ratio ) was 6.6%; the above-mentioned slurry was poured into a circular stainless steel mold with a diameter of 35cm and paved to form a cake with a thickness of about 2.2cm; the cake and the mold were left to stand at room temperature for 12 hours and then put into Take it out after heating to 80°C for 4 hours in a blast drying oven, and heat it to 850°C in a muffle furnace for 5 hours to completely carbonize the hydroxyethyl cellulose in the material. After cooling to room temperature, the black foamy material in the mold is taken out to obtain a graphene foam material with good mechanical strength. Treating the bottom surface (the side soaked in water) with oxygen plasma for 10 minutes can make the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com