Adhesive composition

A composition, pressure-sensitive adhesive technology, applied in the field of OED manufacturing, can solve the problems of unobtainable lamination performance, low reliability, low processability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

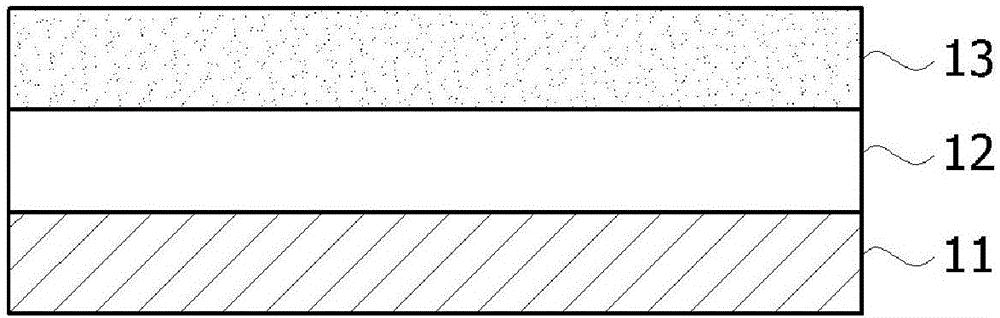

[0112] Add 50 g of butyl rubber (Br068, EXXON) as a polymer derived from butene; 24 g of hydrogenated hydrocarbon resin (Eastotac H-100L) as a tackifier; 15 g of monofunctional acrylate, i.e., 2-(2- Ethoxyethoxy) ethyl acrylate as a compound of formula 1; 10 g of trimethylolpropane triacrylate as a polyfunctional active energy ray polymerizable compound; and 1 g of 2,2-dimethoxy-1 , 2-diphenylethan-1-one (Irgacure 651, Ciba) was used as a radical initiator, and the resulting mixture was diluted with toluene to a solid content of about 15 wt%, to prepare a coating solution.

[0113] The release surface of the peeled PET was coated with the prepared solution, and the coated product was dried in an oven at 100° C. for 15 minutes to obtain a pressure-sensitive adhesive layer with a thickness of 50 μm, which was combined with A copper film with a thickness of 20 μm is laminated to form an encapsulation film. Measure the film sample by 2J / cm 2 Physical properties of UV radiation e...

Embodiment 2

[0115] An encapsulating film was formed by the same method as described in Example 1 except that stearyl acrylate was used instead of the compound of Formula 1.

Embodiment 3

[0117] An encapsulating film was formed by the same method as described in Example 1 except that lauryl acrylate was used instead of the compound of Formula 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com