Thin-film transistor and manufacture method thereof

A technology of thin-film transistors and gate electrodes, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the disadvantages of large-scale production of thin-film transistors, etc., and achieve the effects of light weight, improved performance, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

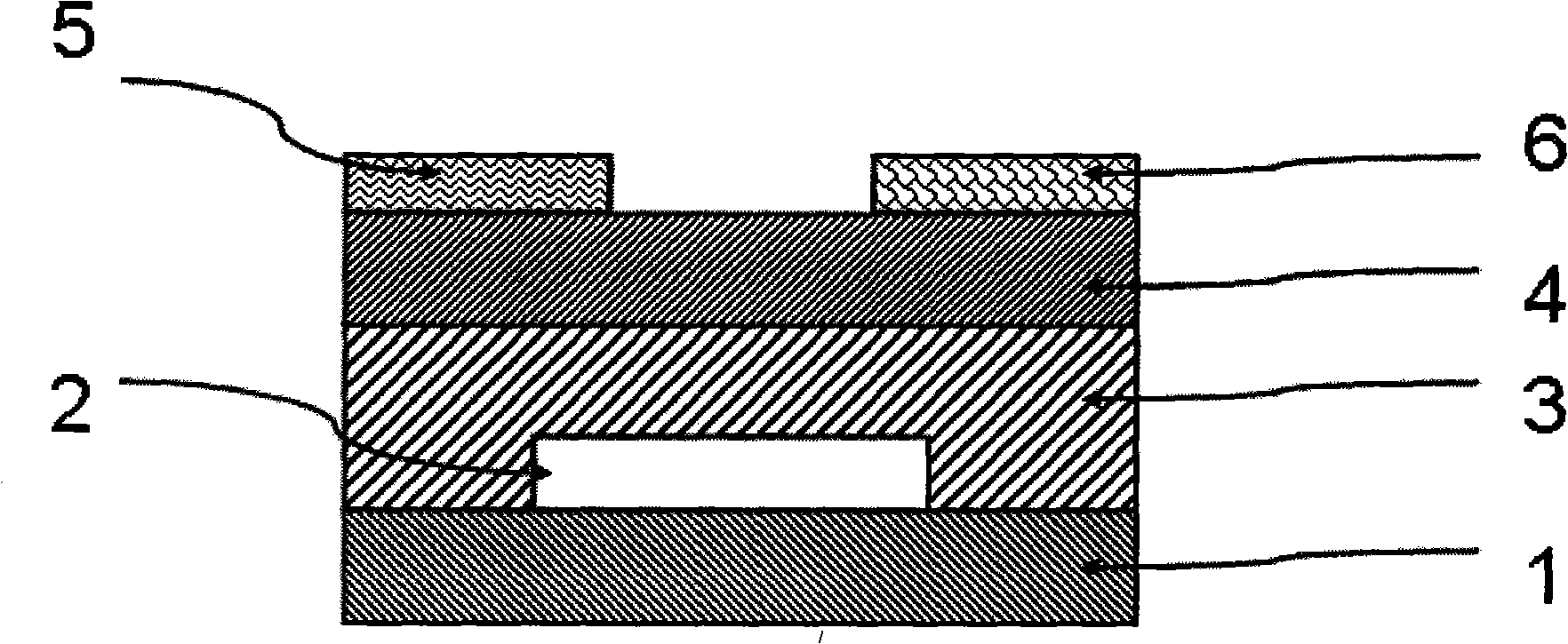

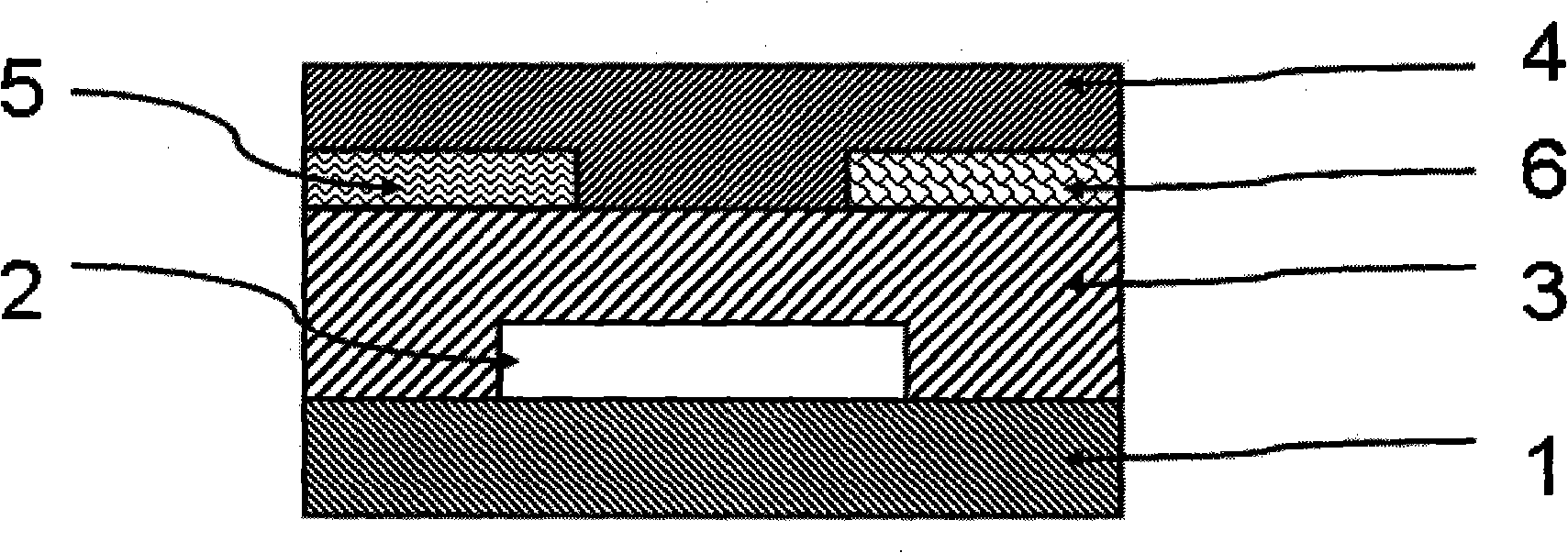

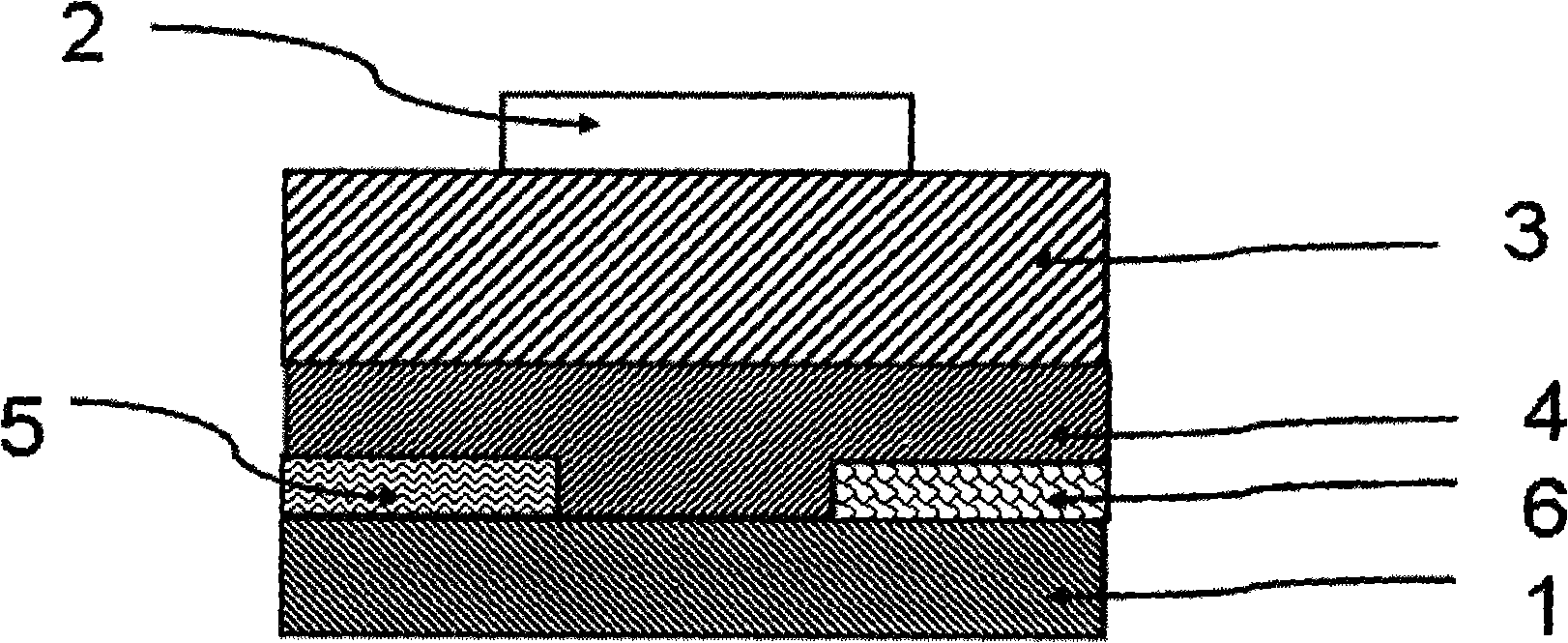

[0044] Such as figure 1 In the structure shown, substrate 1 is made of Si substrate, gate electrode 2 is made of DC magnetron sputtered ITO transparent conductive film, ultraviolet curing glue is used as gate insulating layer 3, source electrode 5 is made of Cr metal film as electrode layer, and drain electrode 6 also uses Cr metal film as the electrode layer. Conductive layer 4 is polysilicon.

[0045] The preparation method is as follows:

[0046] ① Thoroughly clean the Si substrate first, and blow dry with dry nitrogen after cleaning;

[0047] ②Gate electrodes are prepared on the surface of the Si substrate by DC magnetron sputtering;

[0048] ③Etching the ITO gate electrode pattern by photolithography;

[0049] ④ Spin-coat the UV-curable adhesive grid insulating film on the Si substrate coated with the gate electrode by spin-coating method;

[0050] ⑤ Carrying out ultraviolet curing and heating and baking the formed organic gate insulating film;

[0051] 6. Prepare a...

Embodiment 2

[0055] Such as figure 1 In the structure shown, substrate 1 is made of Si substrate, gate electrode 2 is made of DC magnetron sputtered ITO transparent conductive film, ultraviolet curing glue and silicon dioxide are used as gate insulating layer 3, and source electrode 5 is made of Cr metal film as electrode layer, and the drain electrode 6 also uses Cr metal thin film as the electrode layer. Conductive layer 4 is polysilicon.

[0056] The fabrication process of the device is similar to that of Example 1.

Embodiment 3

[0058] Such as figure 1 In the structure shown, substrate 1 is made of Si substrate, gate electrode 2 is made of DC magnetron sputtered ITO transparent conductive film, ultraviolet curing glue and silicon dioxide are used as gate insulating layer 3, and source electrode 5 is made of Cr metal film as electrode layer, and the drain electrode 6 also uses Cr metal thin film as the electrode layer. Conductive layer 4 is amorphous silicon.

[0059] The fabrication process of the device is similar to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com