A kind of preparation method of sintered NdFeB sheet magnet

A neodymium-iron-boron and sheet technology, which is applied in the fields of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of insufficient improvement ability, reduced magnetic flux of sintered neodymium-iron-boron sheet magnets, limited effect, etc., to avoid The effect of grain size refinement, improvement of low magnetic phenomenon, reduction of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

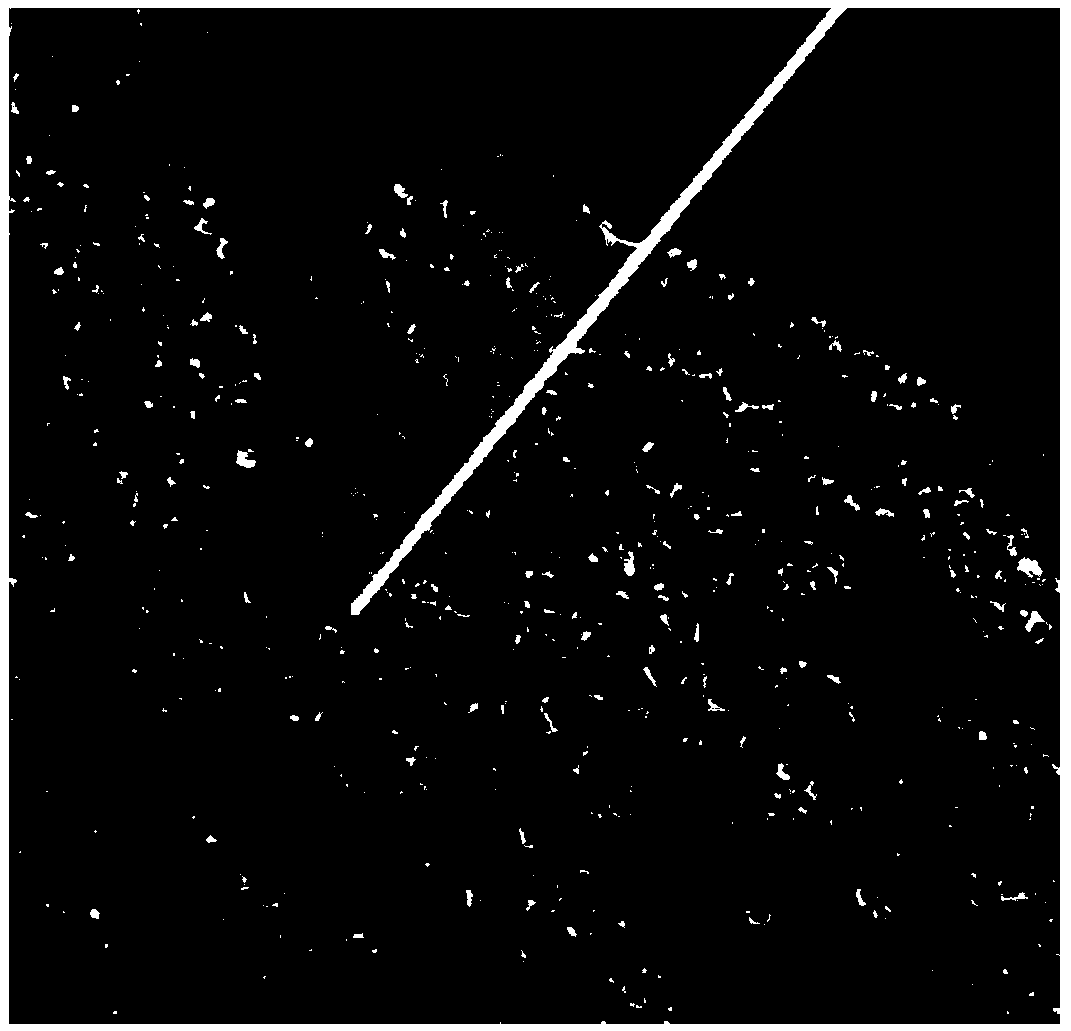

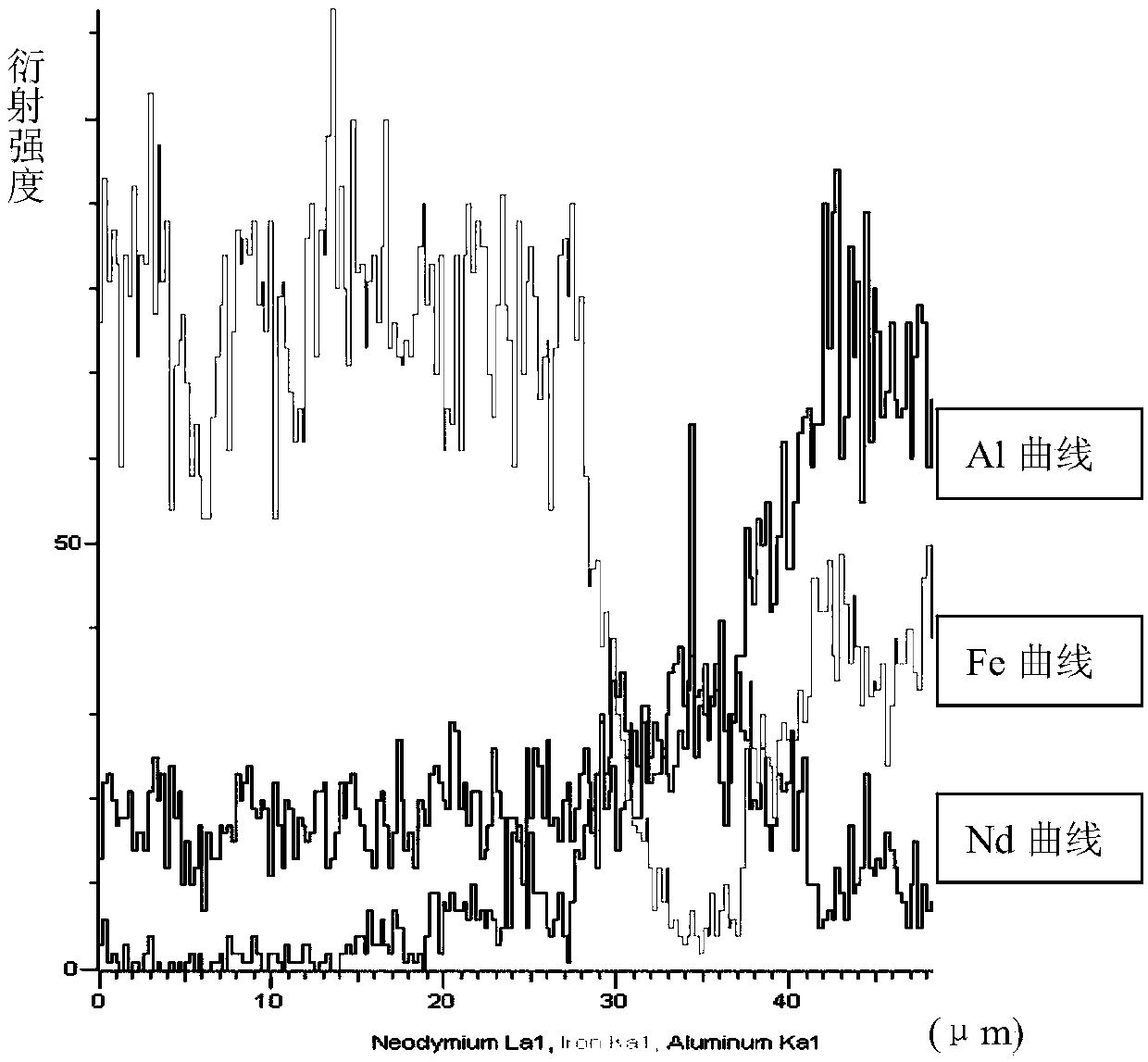

Image

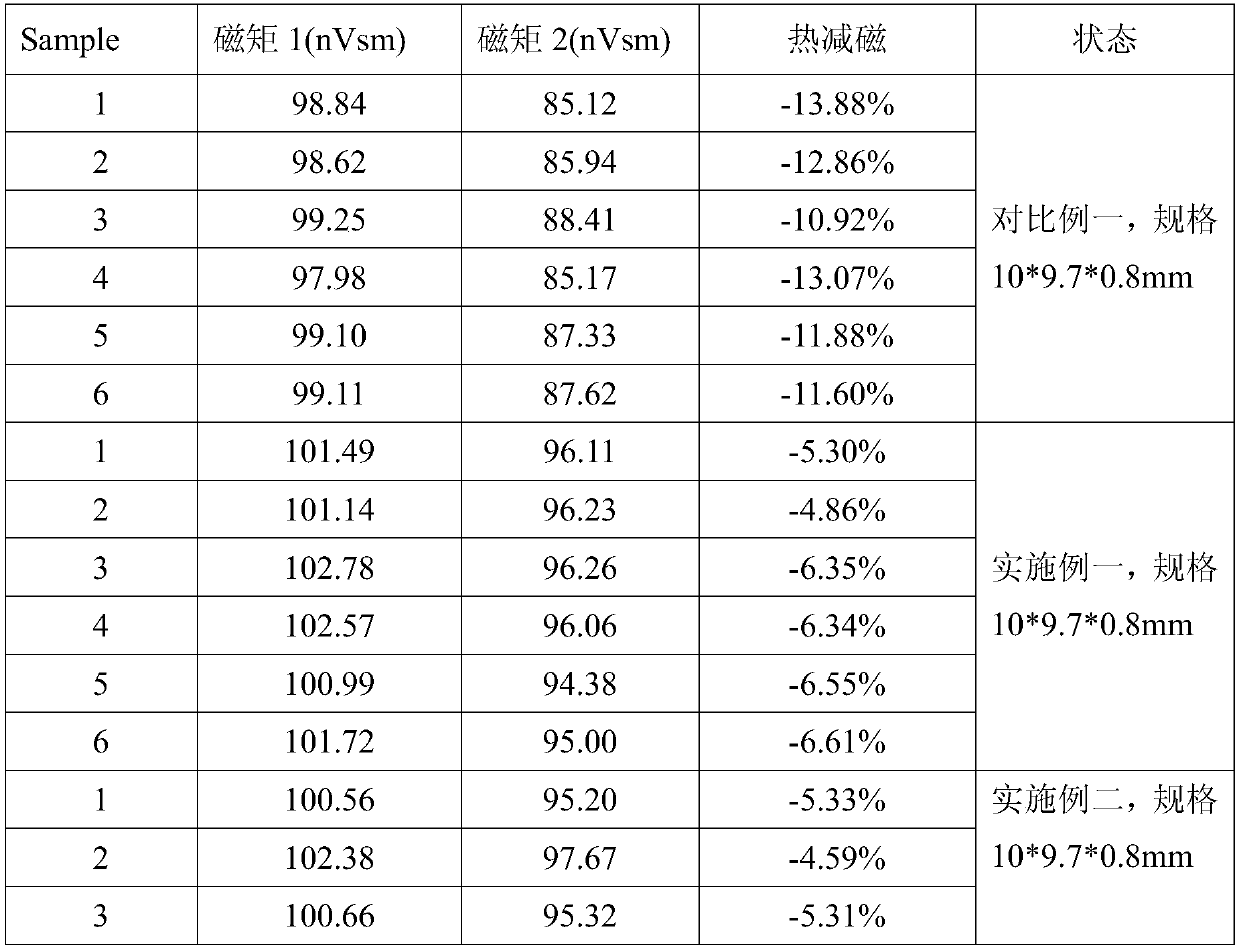

Examples

Embodiment 1

[0027] Embodiment 1: A kind of preparation method of sintered NdFeB sheet magnet, comprises the following steps:

[0028]① Configure the raw materials of sintered NdFeB sheet magnets according to the design requirements, melt the raw materials in a vacuum electromagnetic induction furnace, cast them into quick-setting sheets with a thickness of 0.2-0.6mm at a temperature of 1450°C, and then speed them up in a hydrogen crushing furnace The condensed sheet is subjected to hydrogen crushing treatment to obtain a coarse powder with a particle size of 0.1-3mm, and then the coarse powder is accelerated by a high-pressure gas of 0.4-0.6Mpa in the airflow milling equipment to make it collide with each other to form a specific surface area and an average particle size 2.0 ~ 4.0μm powder;

[0029] ②Put the powder into the mold cavity of the forming press, and press the powder under the action of the orientation magnetic field to obtain a sintered NdFeB green body;

[0030] ③ Sintering ...

Embodiment 2

[0039] Embodiment two: a kind of preparation method of sintered NdFeB sheet magnet, comprises the following steps:

[0040] ① Configure the raw materials of sintered NdFeB sheet magnets according to the design requirements, melt the raw materials in a vacuum electromagnetic induction furnace, cast them into quick-setting sheets with a thickness of 0.2-0.6mm at a temperature of 1450°C, and then speed them up in a hydrogen crushing furnace The condensed sheet is subjected to hydrogen crushing treatment to obtain a coarse powder with a particle size of 0.1-3mm, and then the coarse powder is accelerated by a high-pressure gas of 0.4-0.6Mpa in the airflow milling equipment to make it collide with each other to form a specific surface area and an average particle size 2.0 ~ 4.0μm powder;

[0041] ②Put the powder into the mold cavity of the forming press, and press the powder under the action of the orientation magnetic field to obtain a sintered NdFeB green body;

[0042] ③ Sinteri...

Embodiment 3

[0051] Embodiment three: a kind of preparation method of sintered NdFeB sheet magnet, comprises the following steps:

[0052] ① Configure the raw materials of sintered NdFeB sheet magnets according to the design requirements, melt the raw materials in a vacuum electromagnetic induction furnace, cast them into quick-setting sheets with a thickness of 0.2-0.6mm at a temperature of 1450°C, and then speed them up in a hydrogen crushing furnace The condensed sheet is subjected to hydrogen crushing treatment to obtain a coarse powder with a particle size of 0.1-3mm, and then the coarse powder is accelerated by a high-pressure gas of 0.4-0.6Mpa in the airflow milling equipment to make it collide with each other to form a specific surface area and an average particle size 2.0 ~ 4.0μm powder;

[0053] ②Put the powder into the mold cavity of the forming press, and press the powder under the action of the orientation magnetic field to obtain a sintered NdFeB green body;

[0054] ③ Sinte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com