Quenching method for high alloy carburizing steel gear

A technology of alloy carburizing steel and gears, which is applied in the field of heat treatment, can solve the problems of coarse martensitic needles, low surface hardness of gears, reduction of gear wear resistance, strength and toughness, and comprehensive mechanical properties, so as to reduce quenching deformation, reduce Effect of Quenching Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

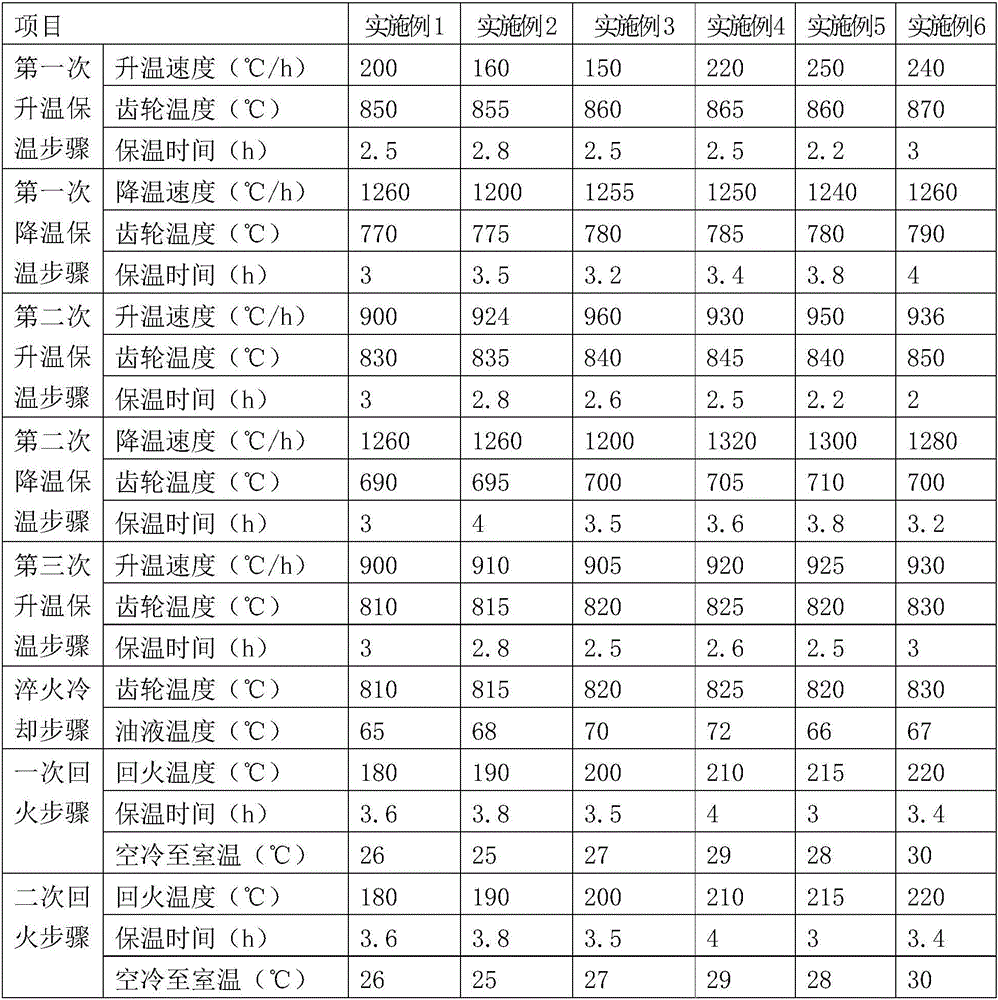

Examples

Embodiment Construction

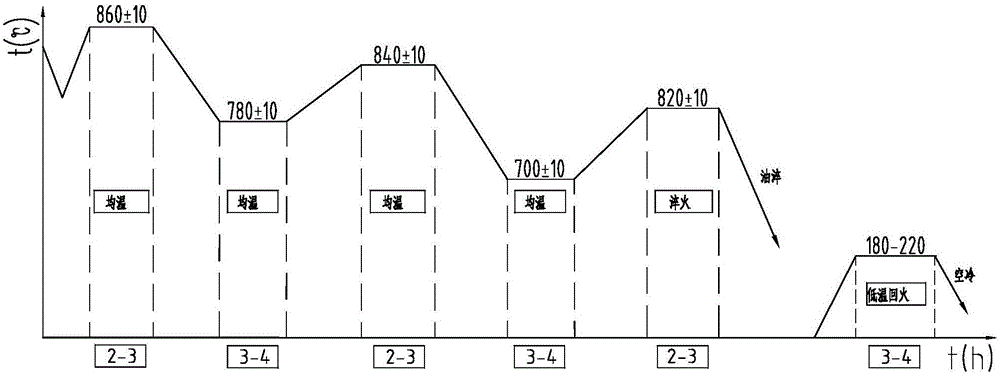

[0022] See figure 1 As shown, the quenching method of the high-alloy carburized steel gear of the present invention includes the following steps.

[0023] (1) The first heating and heat preservation step: heat the carburized gear to 860±10°C with the furnace, and the heat preservation time is 2 to 3 hours. By heating the gear to 860±10°C and holding it for a period of time, the surface layer of the gear will The tenite precipitates carbides and transforms into austenite and cementite, and the austenite in the center transforms into austenite and ferrite.

[0024] (2) The first cooling and heat preservation step: the gear is rapidly cooled to 780±10°C, and the heat preservation time is 3 to 4 hours. The speed of rapid cooling of the gear of the present invention is ≥ 1200°C / h, if the cooling speed is 1260°C / h, The gear is lowered from 860±10°C to 780±10°C, and through rapid cooling, the metallographic structure of the gear can be well refined, making the ferrite and cementite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com