Surface treatment coating for biochemical pharmaceutical carrying vessel

A surface treatment and biochemical technology, applied in the direction of coatings, fireproof coatings, paints containing biocide, etc., can solve the problems of affecting the use effect and single function, and achieve the effect of improving product performance and superior flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

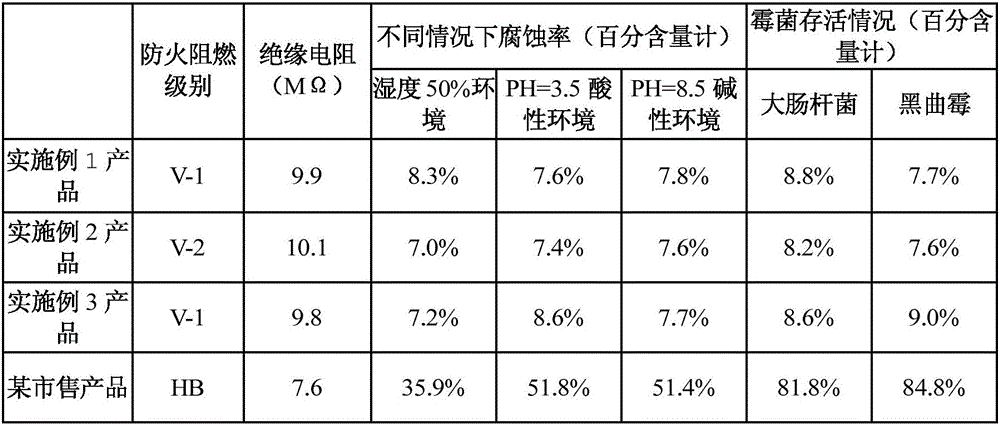

Examples

Embodiment 1

[0027]The surface treatment coating of the biochemical pharmaceutical carrier vessel in this embodiment is composed of the following components in parts by mass: 28 parts of acrylate rubber powder, 26 parts of polyurethane resin, 26 parts of polyvinyl chloride, 24 parts of carbo resin, isocyanate 26 parts of butyltriethoxysilane, 26 parts of epichlorohydrin, 24 parts of litsea cubeba oil, 26 parts of hydrogenated castor oil, 26 parts of dioctadecyldimethylammonium chloride, polyhexamethylene biguanide 24 parts of hydrochloride, 24 parts of methyl p-hydroxybenzoate, 24 parts of sodium dehydroacetate, 26 parts of niobium carbide powder, 24 parts of barium carbonate powder, 22 parts of potassium carbonate powder, 26 parts of manganese carbonate powder, calcium bicarbonate powder 24 parts, silver carbonate powder 22 parts, potassium ferricyanate 24 parts, copper powder 22 parts, pyromellitic dianhydride 22 parts, zinc phosphate 22 parts, triethylene glycol diisocaprylate 20 parts, ...

Embodiment 2

[0038] The surface treatment coating of the biochemical pharmaceutical carrier vessel in this embodiment is composed of the following components in parts by mass: 30 parts of acrylate rubber powder, 28 parts of polyurethane resin, 28 parts of polyvinyl chloride, 26 parts of carbomer resin, isocyanate 28 parts of butyltriethoxysilane, 28 parts of epichlorohydrin, 26 parts of litsea cubeba oil, 28 parts of hydrogenated castor oil, 28 parts of dioctadecyldimethylammonium chloride, polyhexamethylene biguanide 26 parts of hydrochloride, 26 parts of methyl p-hydroxybenzoate, 26 parts of sodium dehydroacetate, 28 parts of niobium carbide powder, 26 parts of barium carbonate powder, 24 parts of potassium carbonate powder, 28 parts of manganese carbonate powder, calcium bicarbonate powder 26 parts, silver carbonate powder 24 parts, potassium ferricyanate 26 parts, copper powder 24 parts, pyromellitic dianhydride 24 parts, zinc phosphate 24 parts, triethylene glycol diisocaprylate 22 par...

Embodiment 3

[0049] The surface treatment coating of the biochemical pharmaceutical carrier vessel in this embodiment is composed of the following components in parts by mass: 32 parts of acrylate rubber powder, 30 parts of polyurethane resin, 30 parts of polyvinyl chloride, 28 parts of carbomer resin, isocyanate 30 parts of butyltriethoxysilane, 30 parts of epichlorohydrin, 28 parts of litsea cubeba oil, 30 parts of hydrogenated castor oil, 30 parts of dioctadecyldimethylammonium chloride, polyhexamethylene biguanide 28 parts of hydrochloride, 28 parts of methyl p-hydroxybenzoate, 28 parts of sodium dehydroacetate, 30 parts of niobium carbide powder, 28 parts of barium carbonate powder, 26 parts of potassium carbonate powder, 30 parts of manganese carbonate powder, calcium bicarbonate powder 28 parts, silver carbonate powder 26 parts, potassium ferricyanate 28 parts, copper powder 26 parts, pyromellitic dianhydride 26 parts, zinc phosphate 26 parts, triethylene glycol diisocaprylate 24 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com