Injectable hydrogel with self-healing and pH response properties, and preparation method and application thereof

A technology for injecting water and performance, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, organic active ingredients, etc. It can achieve the effect of excellent self-healing performance and obvious pH response performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a novel injectable hydrogel with self-healing and pH-responsive properties, comprising the following steps:

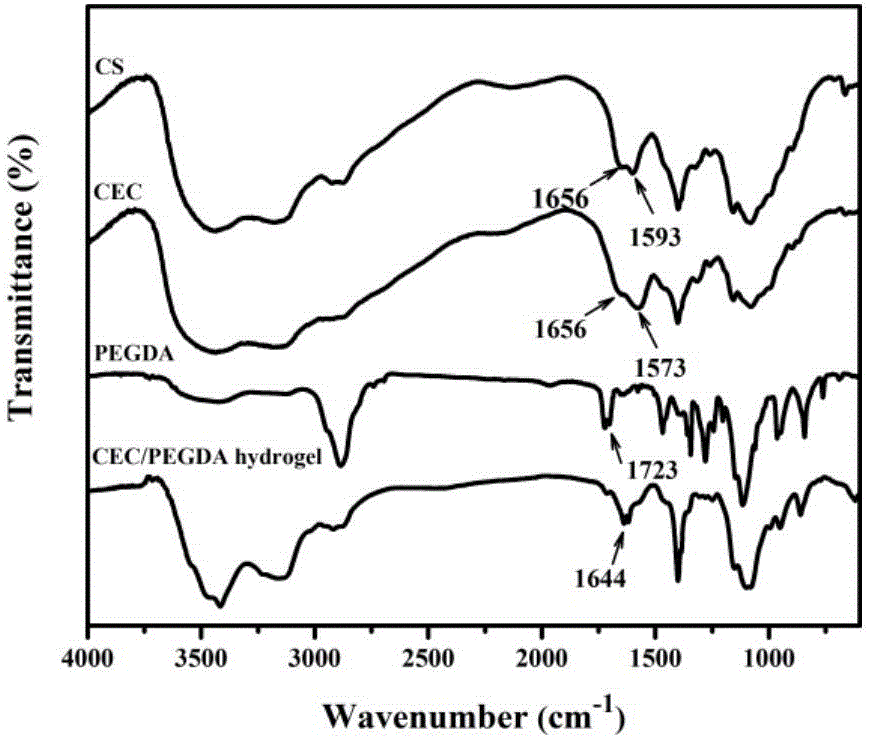

[0044] 1) Preparation of CEC (N-carboxyethyl chitosan) polymer: Add chitosan and acrylic acid to deionized water at a mass-volume ratio of 4g:(5-6)mL and react at 40-60°C to remove The amount of ionized water added is based on the ability to dissolve chitosan and acrylic acid. The ratio of chitosan to deionized water is 4g: (150-200) mL. After 65 hours, the CEC polymer is obtained, and the reaction is preferably 65-75 hours;

[0045] 2) Preparation of PEGDA (Dibenzaldehyde-Terminated Poly(ethyleneglycol), benzaldehyde-terminated polyethylene glycol) polymer: under nitrogen atmosphere, inert gas or vacuum environment, polyethylene glycol (PEG), p-formaldehyde Acylbenzoic acid and 4-dimethylaminopyridine are reacted in anhydrous tetrahydrofuran solvent, and N,N'-dicyclohexylcarboimide is added after 10-30 minutes. The total reaction time is ...

Embodiment 1

[0052] 1) Preparation of CEC (N-carboxyethyl chitosan) polymer: Add 5.84mL of acrylic acid to a round bottom flask filled with 200mL of deionized water, heat up to 50°C, and then add 4g of chitosan Sugar powder, stirred and reacted for 3 days, adjusted the pH to 9-10 with 1M NaOH aqueous solution to generate carboxylate; the reaction solution was dialyzed in deionized water for 2 days with a dialysis membrane with an average molecular weight of 8000 to remove excess salt, and the product was in - Freeze at 80°C, and use a freeze dryer to obtain a freeze-dried product after two to three days;

[0053] 2) Preparation of PEGDA (Dibenzaldehyde-Terminated Poly(ethyleneglycol), benzaldehyde-terminated polyethylene glycol) polymer: 4.89g of polyethylene glycol (PEG2000), 1.47g of p-formylbenzoic acid and 0.075g of 4-Dimethylaminopyridine was added to a 100mL round-bottomed flask, reacted at room temperature under nitrogen atmosphere for 20 minutes, then added 2.52g of N,N'-dicyclohex...

Embodiment 2

[0056] 1) Preparation of CEC (N-carboxyethyl chitosan) polymer: Add 5.84mL of acrylic acid to a round bottom flask filled with 200mL of deionized water, heat up to 50°C, and then add 4g of chitosan Sugar powder, stirred and reacted for 3 days, adjusted the pH to 9-10 with 1M NaOH aqueous solution to generate carboxylate; the reaction solution was dialyzed in deionized water for 2 days with a dialysis membrane with an average molecular weight of 8000 to remove excess salt, and the product was in - Freeze at 80°C, and use a freeze dryer to obtain a freeze-dried product after two to three days;

[0057] 2) Preparation of PEGDA (Dibenzaldehyde-Terminated Poly(ethyleneglycol), benzaldehyde-terminated polyethylene glycol) polymer: 4.89g of polyethylene glycol (PEG2000), 1.47g of p-formylbenzoic acid and 0.075g of 4-Dimethylaminopyridine was added to a 100mL round-bottomed flask, reacted at room temperature under nitrogen atmosphere for 20 minutes, then added 2.52g of N,N'-dicyclohex...

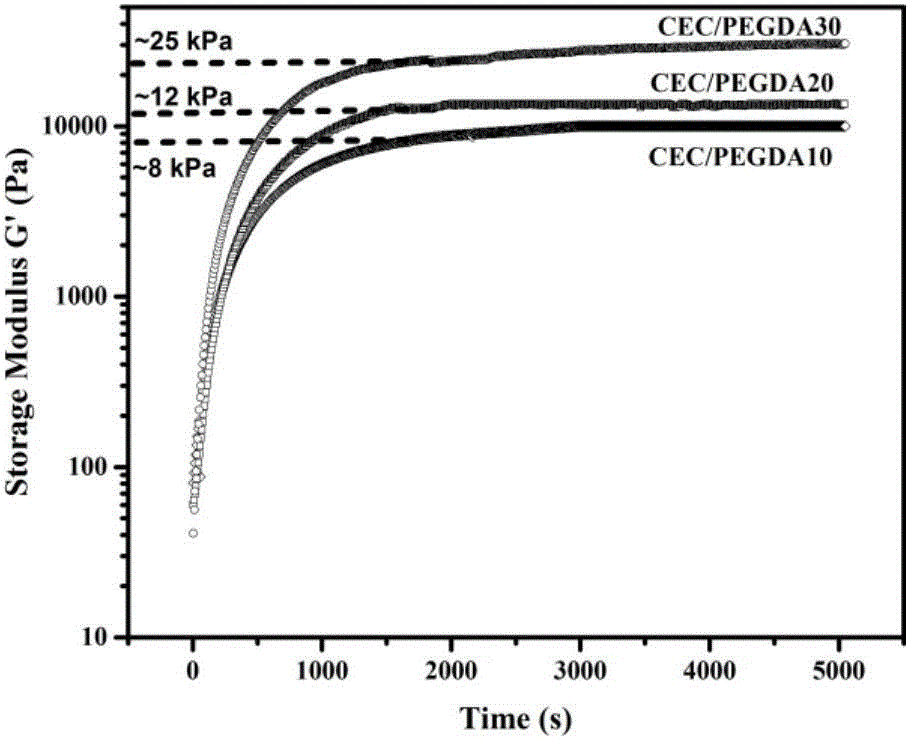

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com