A conductive photothermal self-healing composite hydrogel dressing and its preparation method and application

A composite hydrogel, self-healing technology, applied in the direction of drug combination, pharmaceutical formula, wave energy or particle radiation treatment materials, etc., can solve the problems of limited healing and antibacterial ability, poor treatment effect of infected wounds, etc., to achieve Excellent photothermal antibacterial performance, independent and effective self-repair ability, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention provides a method for preparing a conductive photothermal self-healing composite hydrogel dressing, comprising the steps of:

[0070] S1: Preparation of N- carboxyethyl chitosan polymers: 1) to give chitosan chitosan dispersion was suspended in deionized water, followed by continuous stirring acrylic acid was added dropwise, with stirring at a temperature of 30-80 deg.] C 24-96 hours to obtain a reaction solution; 2) aqueous sodium hydroxide was added to the reaction solution, the reaction solution was adjusted to pH 8-12, then the reaction solution was dialyzed against distilled water, was repeated changing the water 3-5 days, and then freeze-dried, to give N- carboxyethyl chitosan polymers; wherein a mass ratio of chitosan and acrylic acid (2-6) :( 1-8), the concentration of the chitosan dispersion was 15mg / mL ~ 25mg / mL aqueous sodium hydroxide solution at a concentration of 0.5mol / L ~ 2mol / L;

[0071] S2: aldehyde terminated Preparation of ...

Embodiment 1

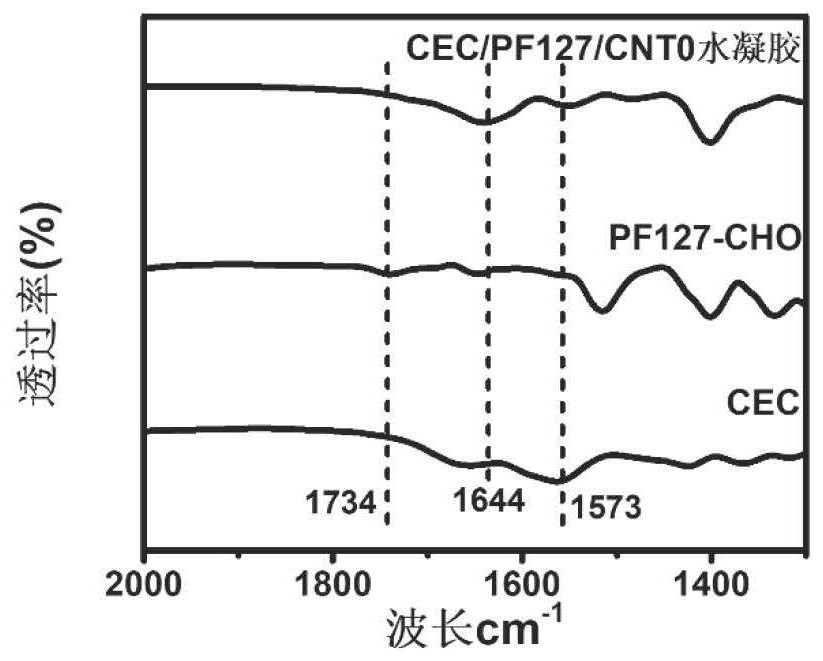

[0092] S1: CEC (N-Carboxyethyl Chitosan, N-Carboxyethyl chitosan) polymer preparation: 4.0 g of chitosan in 200 ml of deionized water, stirring continuously, then 5.84 ml acrylic acid is added to In the suspension, the mixture was continued at 50 ° C for 72 hours, and after the reaction, the pH of the reaction mixture was adjusted to 8-12 with a 1 mol / L sodium hydroxide solution, and the mixture was dialyzed with distilled water (MWCO 8000), and the water was repeated for 3 days. , Then freeze and dried to give pure CEC polymers;

[0093] S2: PF127-CHO (Benzaldehyde-Terminated PF127, aldehyde-based F127) Preparation of the polymer:

[0094] 1) 25g The F127 polymer was sealed in three bottles of nitrogen gas for 30 minutes, and dried under vacuum at 80 ° C for 12 hours, then dried dichloromethane was added, and 2.772 ml of dried triethylamine was added under ice bath at 0 ° C, thoroughly stirred 10 In a minute, 1.584 ml of dried methanesulfonyl chloride was dissolved in 39.6 ml...

Embodiment 2

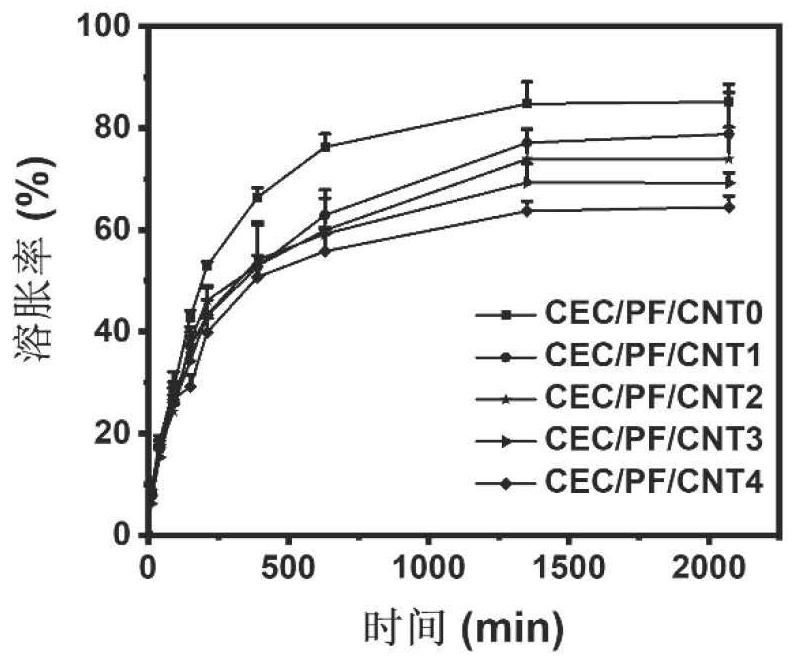

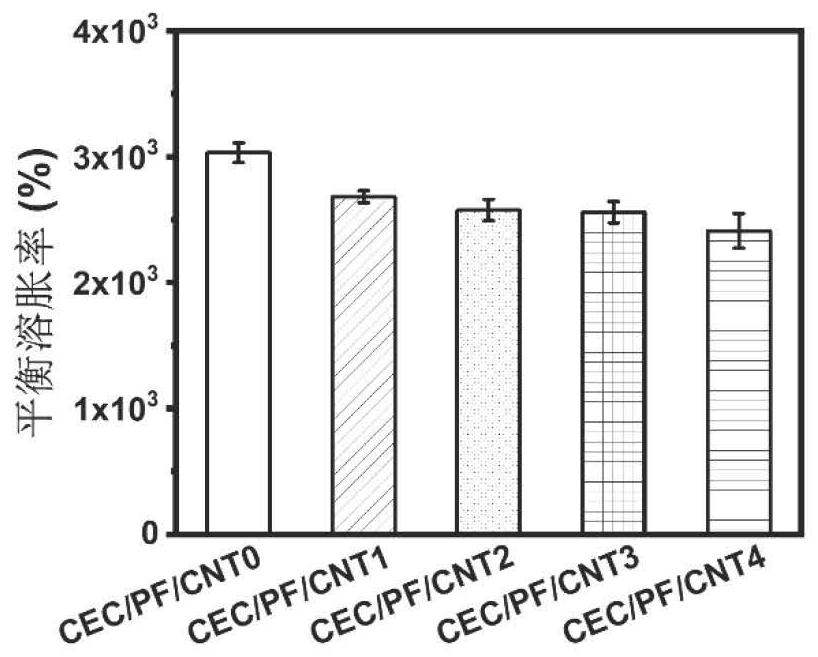

[0099] The aldehyde-based end of step S3 The carbon nanotube (CNTS) final concentration in the F127 / carbon nanotube dispersion was controlled at 8 mg / ml, and the other conditions were as in Example 1 to obtain CEC / PF / CNT2 hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com