A kind of antibacterial adhesive injectable hydrogel dressing and its preparation method and application

A technology for injecting water and gel, applied in pharmaceutical formulations, bandages, drug delivery, etc., can solve the problems of inability to solve patient discomfort, weak mechanical properties, complicated preparation process, etc., achieves obvious pH response performance, excellent self-healing Synthetic properties, rapid drug release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A method for preparing an antibacterial adhesive injectable hydrogel dressing with fast self-healing, easy extension, and easy compression disclosed by the present invention comprises the following steps:

[0060] (1) Preparation of QCS (Quaternized chitosan, quaternized chitosan) polymer:

[0061]Dissolve chitosan in deionized water first, then add glacial acetic acid dropwise while stirring, react at 55°C for 10-300 minutes, then add 2,3-epoxypropyltrimethylammonium chloride, React at 60°C for 12-36 hours, centrifuge the reaction solution at a speed of 2000-6000r / min for 10-30 minutes to obtain a supernatant, add 5-8 times the volume of acetone, the precipitation is complete, and finally filter and dry to obtain a quaternized ammonium shell Polysaccharide polymer; wherein, the mass ratio of chitosan and 2,3-epoxypropyltrimethylammonium chloride is (1-6): (0.5-6).

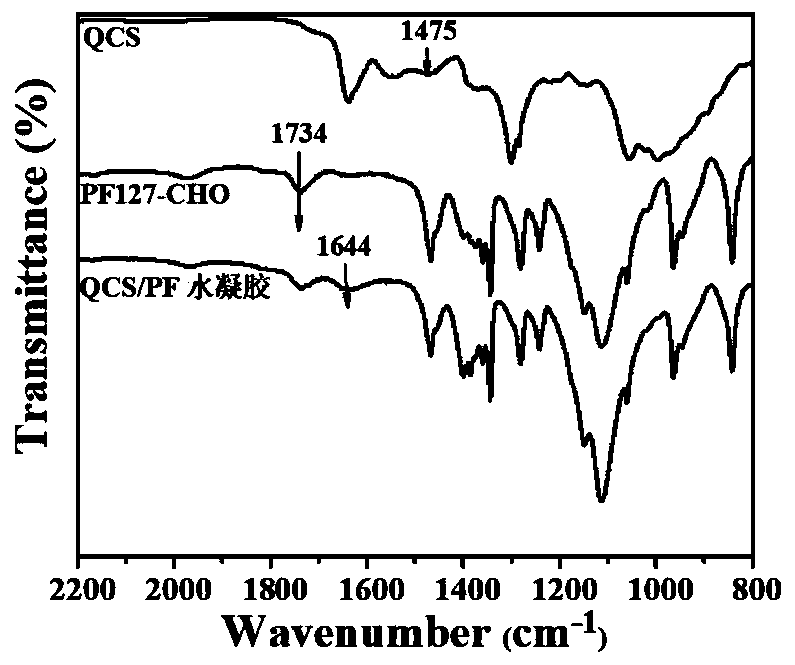

[0062] (2) PF127-CHO (Benzaldehyde-terminated PF127, aldehyde-terminated F127) the preparation of pol...

Embodiment 1

[0086] 1) Preparation of QCS (Quaternized chitosan, quaternized chitosan) polymer: first dissolve 0.5g chitosan in deionized water, then add glacial acetic acid dropwise while stirring, react at 55°C for 180 minutes, and then Add 0.873g of 2,3-epoxypropyltrimethylammonium chloride, react at 55°C for 18 hours, centrifuge the reaction solution at a speed of 4000r / min for 10 minutes to obtain a supernatant, add 5 times the volume of acetone, and the precipitation is complete. Finally, suction drying is obtained to obtain a quaternized chitosan polymer;

[0087] 2) PF127-CHO (Benzaldehyde-terminated PF127, aldehyde-terminated F127) Preparation of polymers:

[0088] (1) put 25g The F127 polymer was sealed in a three-necked flask and dried under vacuum at 90°C for 12 hours, then 200 mL of dry dichloromethane was added, and 2.7 mL of dry triethylamine was added in an ice bath at 0°C, and stirred thoroughly for 10 minutes, and then 16.68 g was dried The methanesulfonyl chloride w...

Embodiment 2

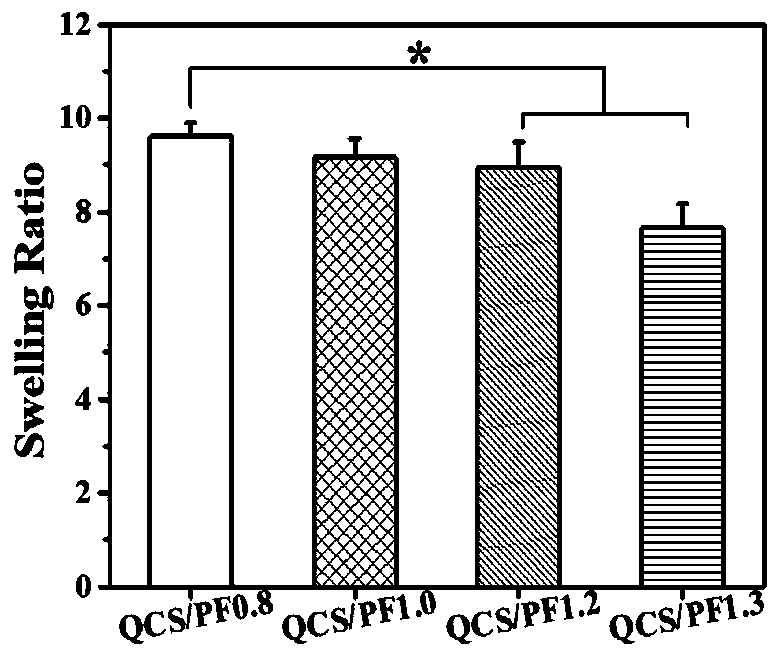

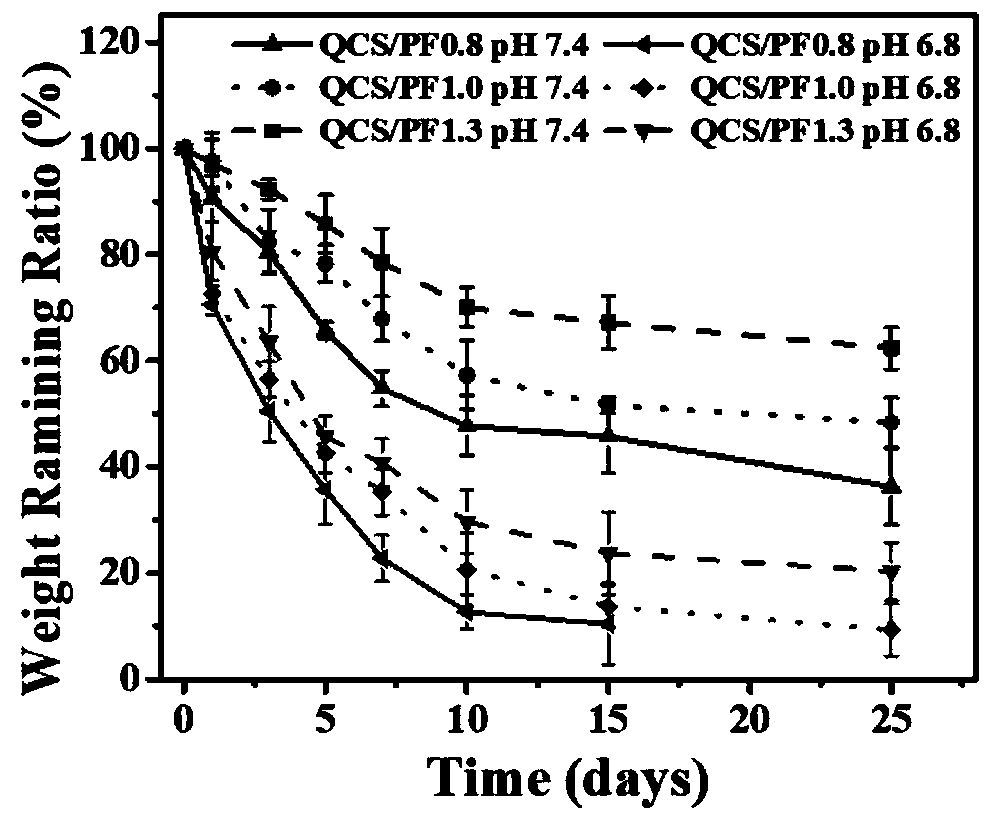

[0092] Different from Example 1, the aldehyde group-terminated in step 3) The F127 polymer solution was replaced with 500mg / mL, 400mg / mL, 360mg / mL, 300mg / mL and 150mg / mL respectively, and the cross-linking time was 15 seconds, 20 seconds, 30 seconds, 55 seconds and 120 seconds respectively, named as QCS / PF1.7, QCS / PF1.3, QCS / PF1.2, QCS / PF1.0, QCS / PF0.5.

[0093] Tested as Figure 8 As shown, when the PF-CHO polymer solution is 400mg / mL, 360mg / mL, 300mg / mL, 240mg / mL respectively, the hydrogel shows a moderate storage modulus, indicating that it has good stability;

[0094] Therefore, in the present invention, the aldehyde-terminated The concentration of the F127 polymer solution is 150-500 mg / mL.

[0095] In the step (3), the quaternized chitosan solution is prepared with a phosphate buffered saline solution, the mass concentration is 20-70 mg / mL, and the aldehyde group-capped F127 polymer solution is prepared with phosphate buffered saline solution, the mass concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com