Carbon-based magnetic solid acid catalyst and application thereof in preparing biodiesel

A magnetic solid acid and biodiesel technology, applied in physical/chemical process catalysts, biofuels, fatty acid esterification, etc., can solve the problems of poor stability, low separation recovery rate, low surface activity, etc., and achieve excellent recycling capacity , good catalytic effect, good catalytic activity and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

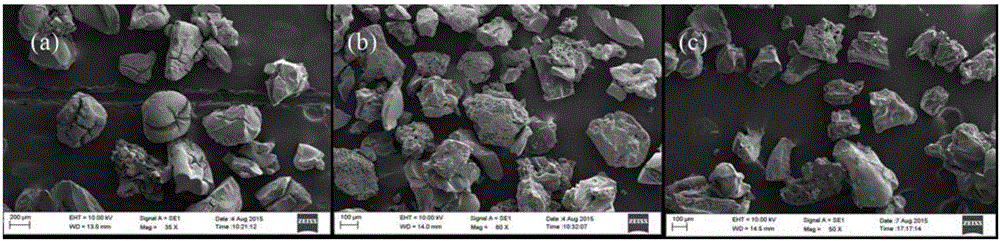

[0038]Take 2g of CMC into 100mL of pure water and heat to dissolve to make solution A; put 40g of ferric sulfate into 100mL of pure water and heat to dissolve to make solution B; under stirring condition, use a syringe to take 100mL of solution A and add dropwise to 100mL of solution In B, the solution was left standing for 3 hours after completion, the solid precipitate was filtered out, washed, dried and ground through a 40-mesh sieve. Take about 10g of the obtained solid and soak it in 50mL of 1mol / L ferric sulfate solution for 3h. The obtained samples were washed, filtered, dried and calcined at 400, 500 and 600 °C for 2 h to obtain the carbon-based magnetic material C 400 / 500 / 600 @Fe.

[0039] figure 1 for C 400 The scanning electron microscope image of @Fe shows that the particle size is about 200 μm.

[0040] figure 2 (a) is C 400 The magnetic saturation intensity curve of @Fe, the magnetic saturation intensity is 6.2Am 2 / g or so.

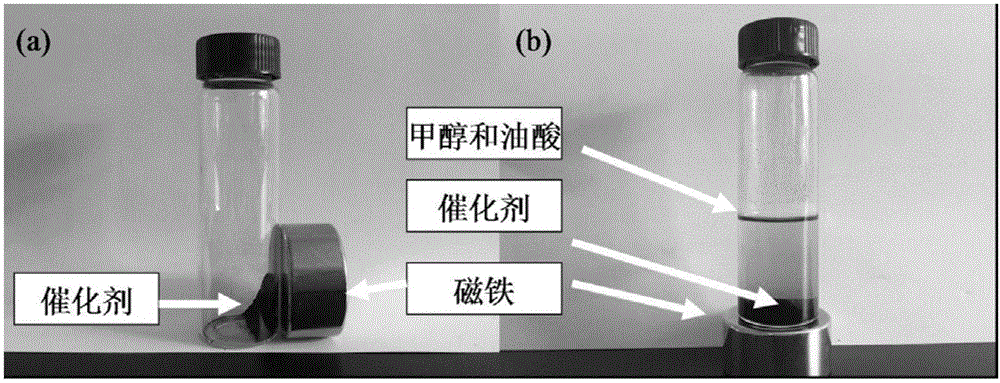

[0041] Take 3g Magnetic C ...

Embodiment 2

[0043] Repeat Example 1, the following difference is arranged: get 1g CMC powder and be dissolved in 100mL pure water and be made into CMC solution, get 80g ferric sulfate and put into 100mL pure water and heat and dissolve and be mixed with Fe 3+ solution. Calcined at 600°C for 2h to obtain carbon-based magnetic material C 600 @Fe-1.

[0044] Take 1g Magnetic C 600 Mix @Fe‐1 and 200mL CMC aqueous solution evenly, and then add dropwise to 200mL0.5mol / L Fe 2 (SO 4 ) 3 In the solution, the solution was continuously stirred on a magnetic stirrer during the dropwise addition to make the chelation reaction fully proceed, and left to stand for 3 hours, then the solid was filtered out and washed and dried. Take 1 g of the dried solid sample, add 100 mL of 98% concentrated sulfuric acid, and sulfonate it in an oil bath at 200 °C for 10 h, wash the solid obtained by sulfonation with pure water at 80 °C until neutral, freeze-dry, grind and pass 200 mesh sieves, prepared carbon-bas...

Embodiment 3

[0046] Repeat Example 1 with the following differences: 5g of CMC powder is dissolved in 100mL of pure water to form a CMC solution.

[0047] Take 5g Magnetic C 400 @Fe was mixed in 200mL CMC solution and dispersed into a suspension. The suspension was added dropwise to 200mL 4mol / L zirconium oxychloride solution, and allowed to stand for 3h. The precipitated solid was filtered off, washed neutral and dried in an oven at 105°C overnight. Take 1 g of the dried solid sample and add it to 10 mL of 98% concentrated sulfuric acid, and sulfonate it in an oil bath at 100° C. for 24 h. The solid produced by sulfonation was washed with hot water at 80°C until neutral, freeze-dried, ground and passed through a 200-mesh sieve to obtain a magnetic solid acid catalyst C 400 -SO 3 H@Zr‐C@Fe‐2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com