Solution-method fume desulfurization and denitrification integral process method

A desulfurization, denitrification and process method technology, applied in the field of environmental protection, can solve the problems of easy volatility, high waste water treatment cost, difficult treatment of oxidant recovery solution, etc., and achieve the effect of reducing supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

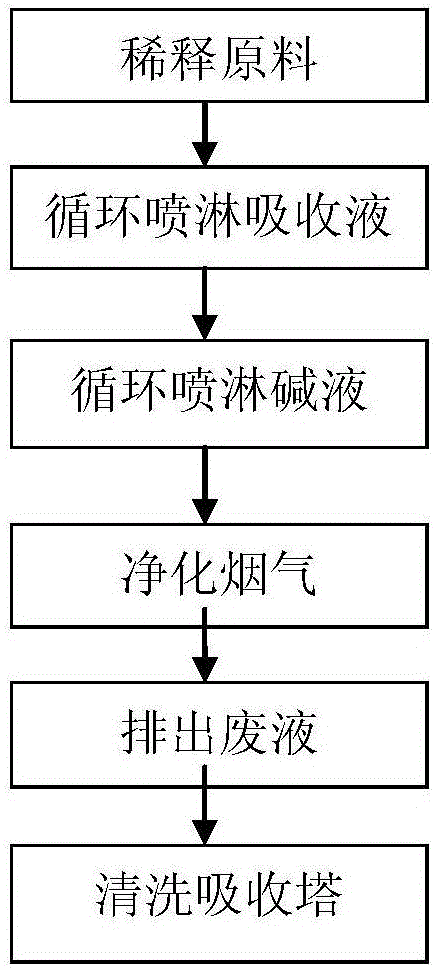

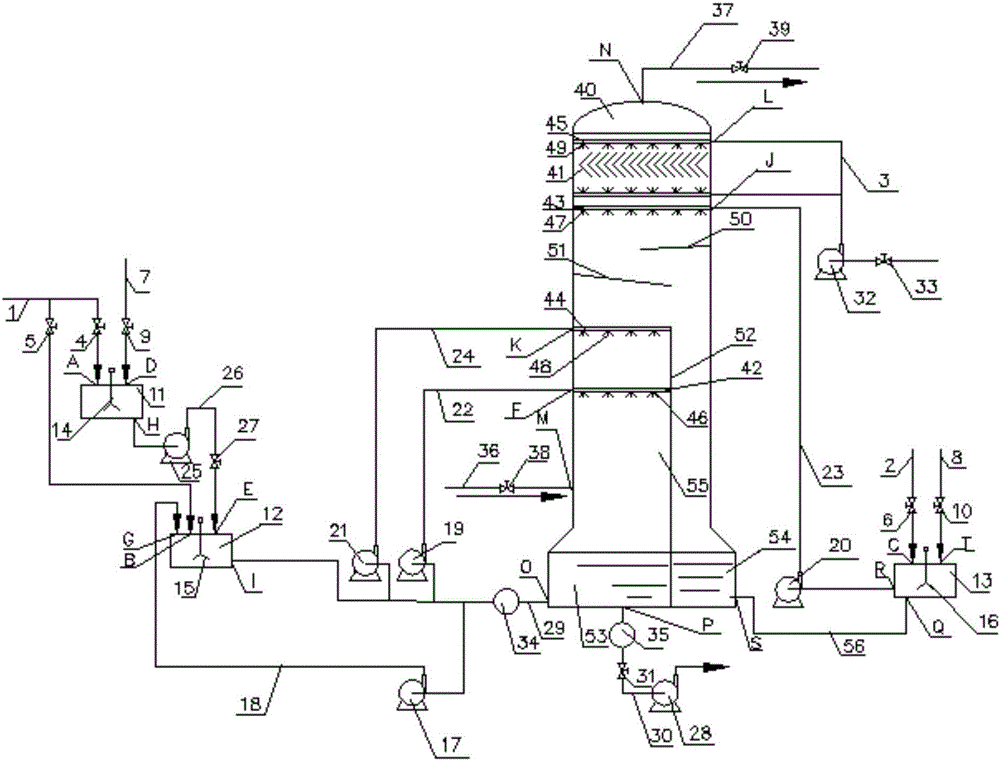

[0056] The solution-based flue gas desulfurization and denitrification integrated process method involved in this embodiment is realized in the flue gas desulfurization and denitrification integrated device, and its specific steps are:

[0057] (1) Dilution of raw materials: first open the first water inlet valve 4 and the first feed pipe valve 9, so that the process water in the first water inlet pipe 1 and the composite absorption liquid raw material in the first feed pipe 7 pass through the first feed pipe 7 respectively. The water inlet A and the first feed port D enter the first liquid tank 11, and then the first agitator 14 in the first liquid tank 11 is turned on, so that the composite absorption liquid raw materials in the first liquid tank 11 are diluted and mixed Uniform;

[0058] (2) Circulating spray absorption liquid: then open the second water inlet valve 5 and the liquid replenishment pipe valve 27, and turn on the liquid replenishment pump 25, so that the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com