A low-temperature pyrolysis system and method for domestic waste

A technology of low-temperature pyrolysis and domestic waste, applied in the field of low-temperature pyrolysis system of domestic waste, which can solve the problems of great differences in product form and components, affecting the type and quality of target products, complex components of domestic waste, etc., and achieve good environmental benefits , Improve energy utilization rate, uniform material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

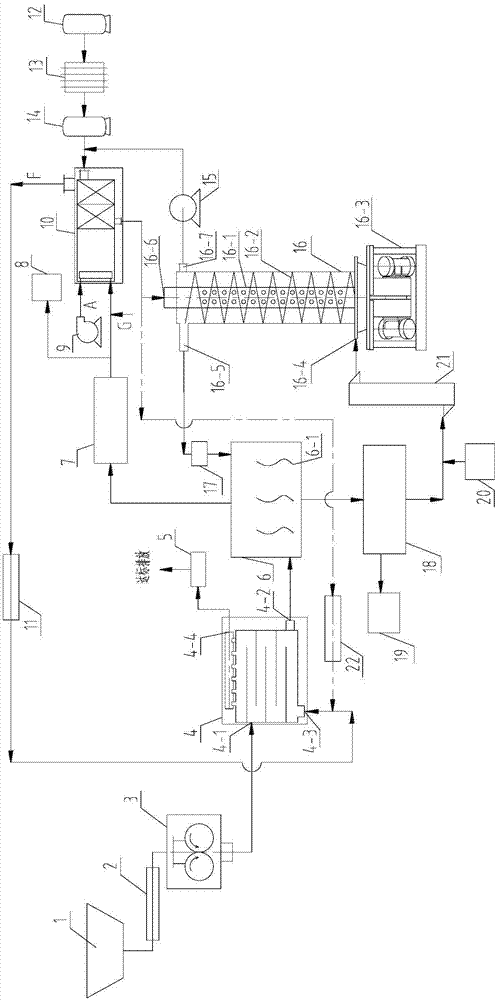

[0026] likefigure 1 As shown, the embodiment of the present invention provides a low-temperature pyrolysis system for domestic waste, which includes a connected twin-shaft crusher 3 and a belt dryer 4, and also includes a pyrolysis device 6, a material separation device 18, and a black carbon collection device 19 , storage bin 20, bucket elevator 21, heat exchange lifting device 16, star unloader 17, pyrolysis gas purification device 7, indirect hot blast stove 10, nitrogen generator, nitrogen circulation fan 15, flue gas purification and deodorization Device 5, cooler I11, cooler II22, specifically, the raw materials can be domestic garbage or stale garbage, biomass, waste rubber, industrial organic waste; the heat transfer medium can be quartz sand or corundum. In this embodiment, the raw material is household garbage, and the heat transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com