A kind of prolific middle distillate hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the secondary pore volume and crystallinity of the depth of dealumination are difficult to take into account, and the contact of macromolecular reactants is not favorable. Reaction, modification of Y molecular sieve crystallinity damage and other problems, to achieve the effect of selectivity and diesel quality improvement, reducing the degree of skeleton damage, and large secondary pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

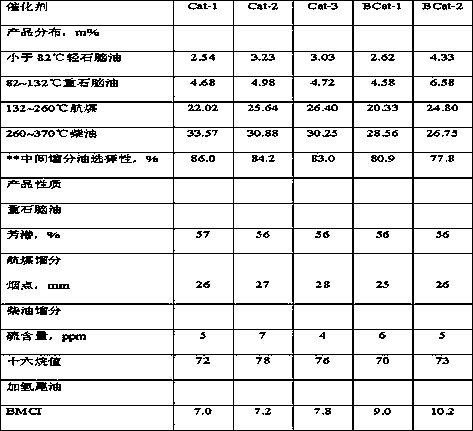

Examples

Embodiment 1

[0023] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 2.3mol / L according to the liquid-solid ratio of 4:1, exchange at 95°C for 2 hours, repeat this process twice, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 0.6%;

[0024] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 630°C and 0.1Mpa for 2 hours;

[0025] (3) Mix the Y molecular sieve obtained in step (2) with a mixed solution containing sodium nitrate and glycerol of 2.8mol / L and 0.4mol / L respectively according to the liquid-solid ratio of 5:1, exchange at 75°C for 1 hour, repeat This process is performed twice, and the Na content in the Y molecular sieve after exchange is represented by Na 2 O is calculated as 4.8%;

[0026](4) The molecular sieve obtained in step (3) is mixed with 0.8 mol / L ammonium fluorosilicate and 0.6 mol / L dilute nitric acid (in the form of H + meter) solution mi...

Embodiment 2

[0033] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium chloride with a concentration of 3.0mol / L according to the liquid-solid ratio of 5:1, exchange at 85°C for 2 hours, repeat this process twice, and the exchanged Y Na content in molecular sieve is Na 2 O is calculated as 0.9%;

[0034] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 670°C and 0.15Mpa for 1.5 hours;

[0035] (3) Mix the Y molecular sieve obtained in step (2) with sodium nitrate with a concentration of 2.5mol / L according to the liquid-solid ratio of 5:1, exchange at 80°C for 1 hour, repeat this process twice, and the Na in the exchanged Y molecular sieve content in Na 2 O is calculated as 3.6%;

[0036] (4) The molecular sieve obtained in step (3) is mixed with the mixed solution of fluorine-containing ammonium silicate and citric acid with concentrations of 1.0mol / L and 0.4mol / L respectively according to the liquid-solid ratio of 5:1,...

Embodiment 3

[0043] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 3.5mol / L according to the liquid-solid ratio of 3:1, exchange at 80°C for 2 hours, repeat this process twice, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 0.8%;

[0044] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 650°C and 0.2Mpa for 2 hours;

[0045] (3) Mix the Y molecular sieve obtained in step (2) with a sodium chloride solution with a concentration of 2.7mol / L according to the liquid-solid ratio of 5:1, exchange at 65°C for 1 hour, repeat this process 3 times, and the Y molecular sieve after exchange Na content in Na 2 O is calculated as 3.8%;

[0046] (4) The molecular sieve obtained in step (3) is mixed with ammonium fluorosilicate solution with a concentration of 1.5 mol / L according to the liquid-solid ratio of 10:1 and beaten, and treated at 95°C for 2 hours;

[0047] (5) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com