A surface plasmon electric excitation and electrical modulation integrated device and its manufacturing method

A surface plasmon, electro-excitation technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as limited application range, surface plasmon modulation without electro-excitation, and inability to integrate devices , to achieve the effect of simple process and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

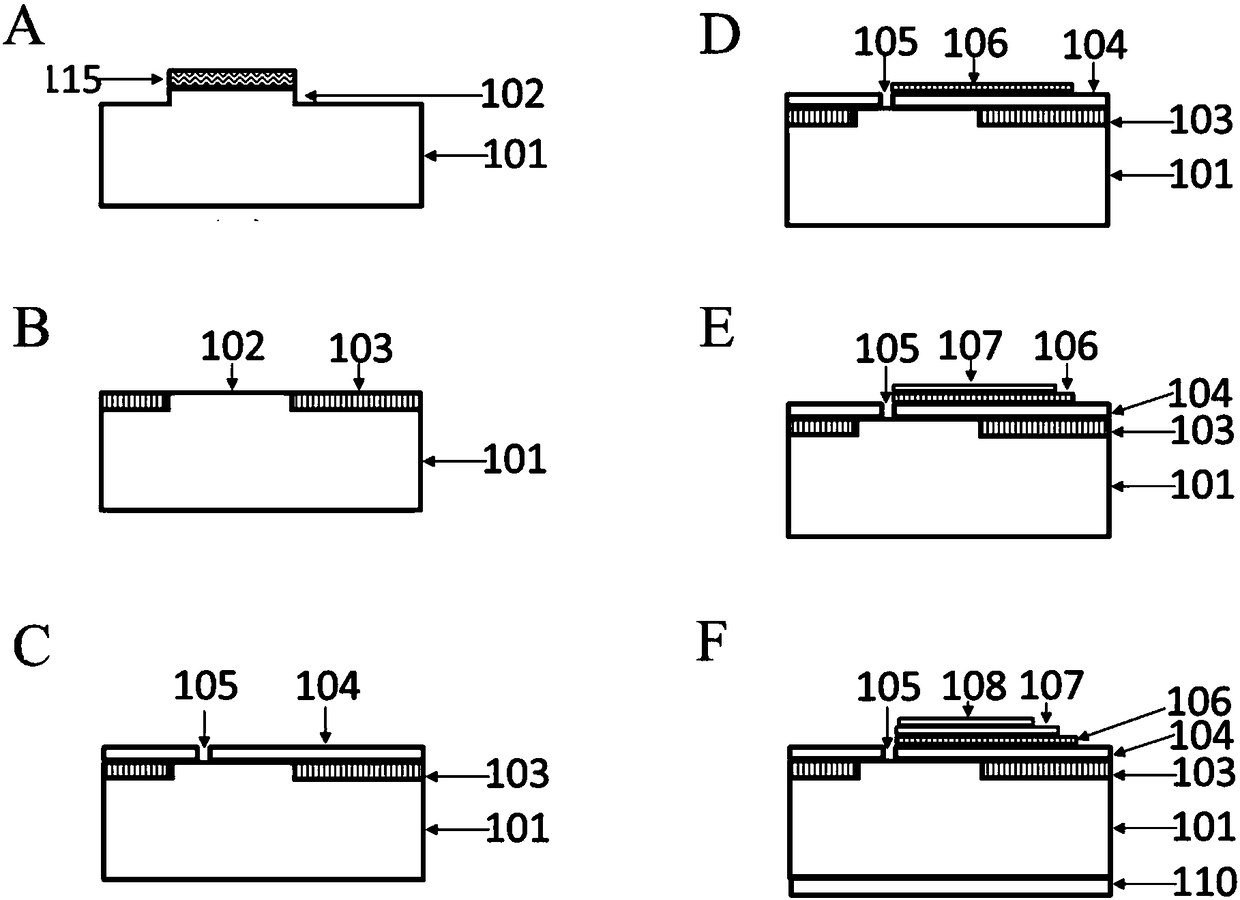

[0056] Taking an indium phosphide (InP)-based quantum well material with a wavelength of λ≈1.55 μm as an example, the structure and manufacturing process of the surface plasmon electric excitation and electrical modulation integrated device of the present invention will be described with reference to the accompanying drawings.

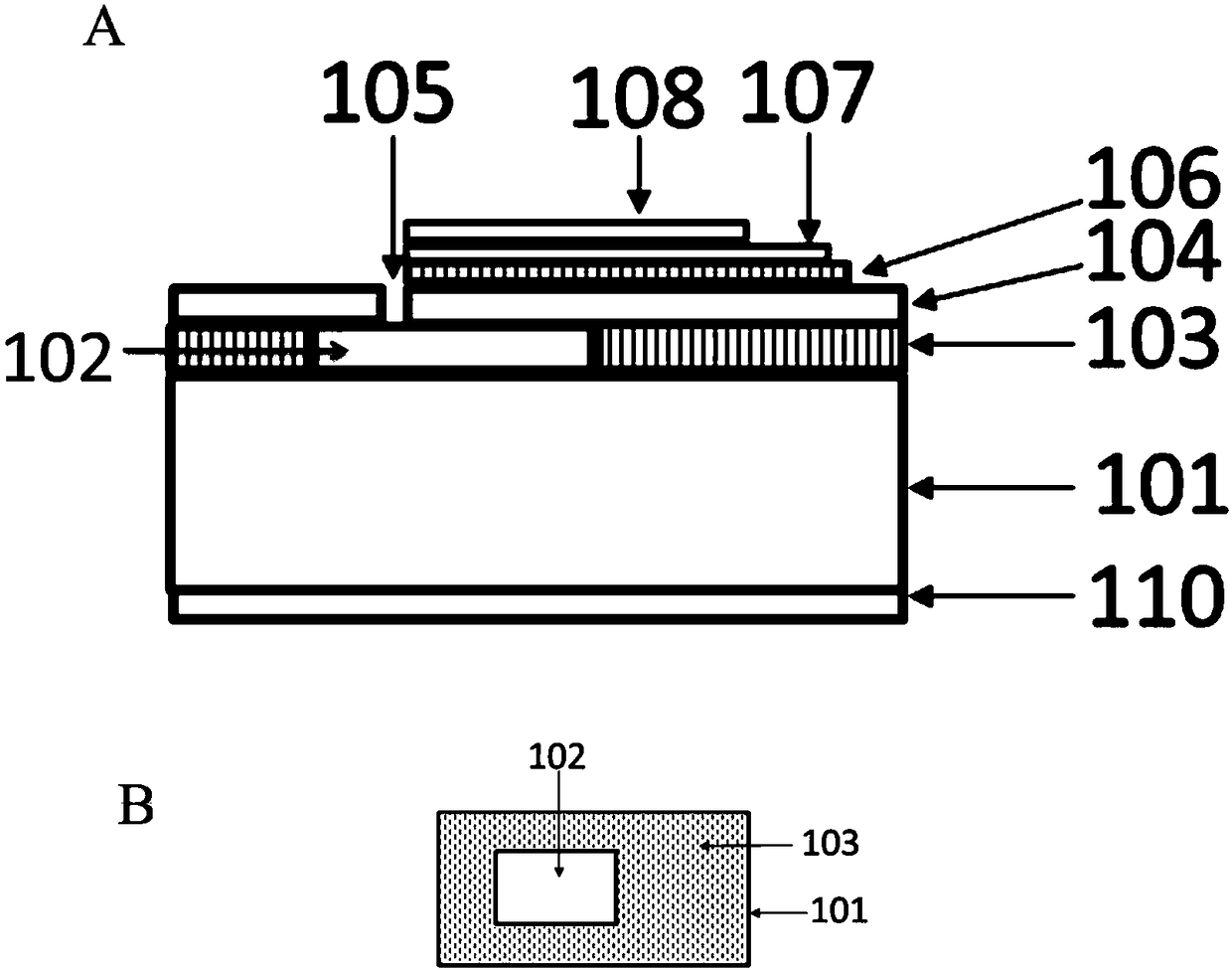

[0057] figure 1 A is a schematic diagram of the structure of the surface plasmon electric excitation and electrical modulation integrated device. Including a semiconductor substrate 101, a semiconductor active structure 102 formed on the semiconductor substrate 101, a first dielectric layer 103 formed around the semiconductor active structure 102 (such as figure 1 Shown in B), the metal electrode and the waveguide structure 104 formed on the semiconductor active structure 102 and the first dielectric layer 103 are formed with the directional coupling structure 105, the second dielectric layer 106 formed on the metal electrode and the waveguide structur...

Embodiment 2

[0069] A surface plasmon electric excitation and electrical modulation integrated device and its manufacturing method, repeating Example 1, the difference is:

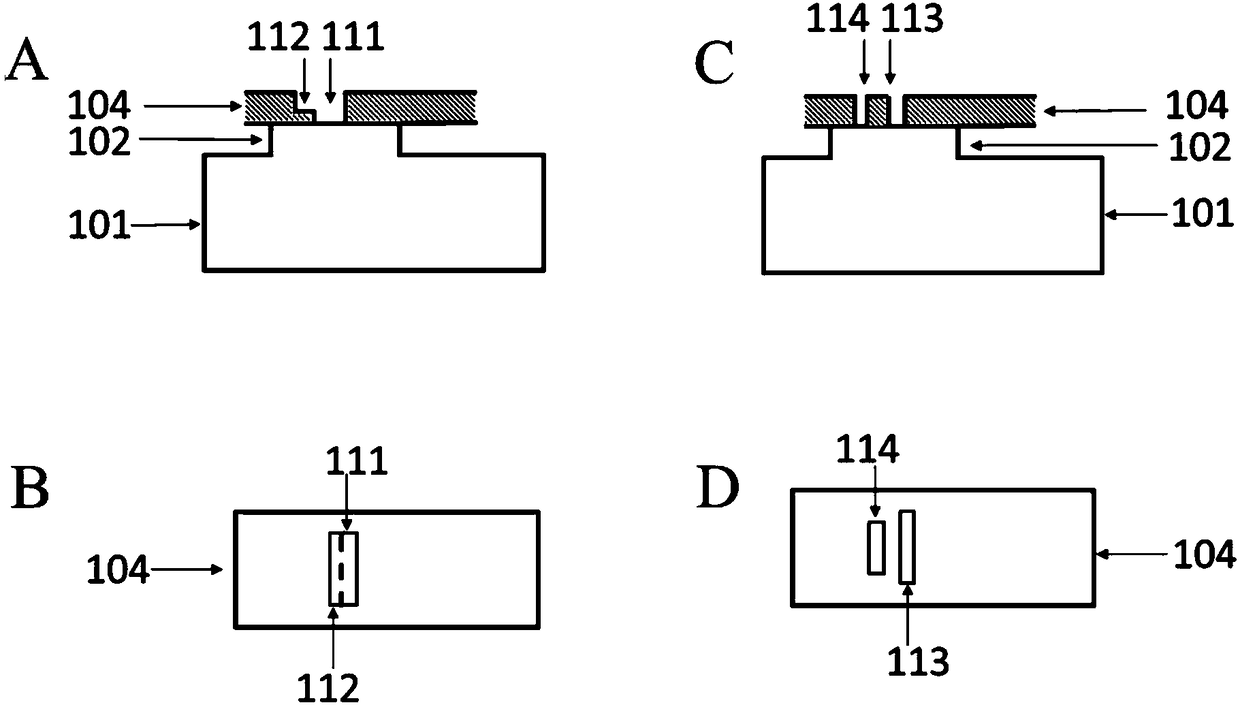

[0070] The thickness of the metal electrodes and waveguide structure 104 is 150-250 nm. The directional coupling structure 105 is composed of asymmetric grooves 113 and 114, such as image 3 C and image 3 As shown in D, the length of the groove 113 is about 200-500nm and the width is about 80-150nm; the length of the groove 114 is 500-1000nm and the width is 80-150nm, and the distance between the centers of the grooves 113 and 114 is 200-400nm. The thickness of the groove 113 and the groove 114 in the directional coupling-out structure 105 does not exceed the thickness of the metal electrode and the waveguide structure 104 .

[0071] The second dielectric layer 106 adopts the material grown by atomic layer deposition-aluminum oxide (Al 2 o 3 ), the growth temperature is 100-140°C, the thickness is 40-80nm, the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com