Cement pipe internal anticorrosion method, anticorrosion paint and preparation method of anticorrosion paint

A technology of anti-corrosion coating and anti-corrosion coating layer, applied in the direction of anti-corrosion coating, epoxy resin coating, coating, etc., can solve the problems of easy leaching, poor adhesion of concrete pipes, no obvious protective effect from oil erosion, etc., and achieve excellent performance , Good surface protection, convenient steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

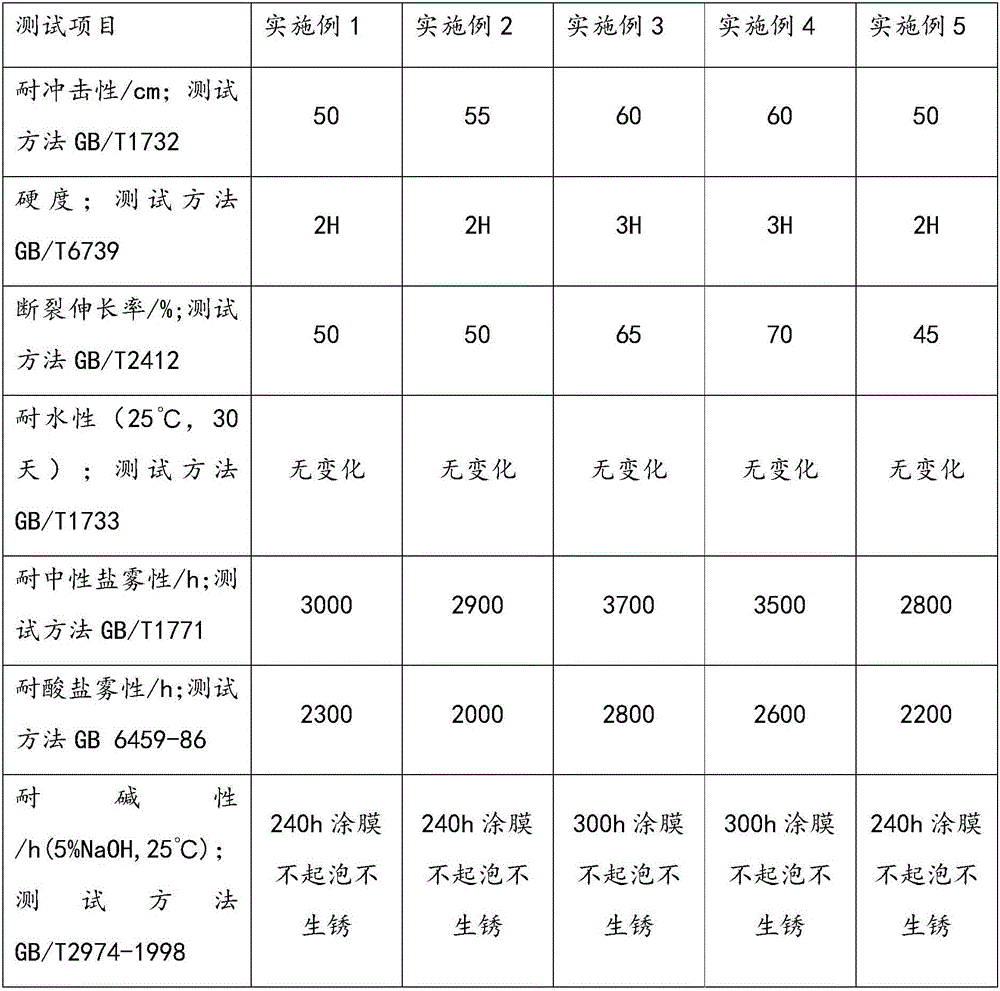

Examples

Embodiment 1

[0040] In parts by mass: 30 parts of epoxy resin, 5 parts of reactive diluent, 10 parts of titanium dioxide, 3 parts of barium sulfate, 5 parts of red iron oxide, 0.5 parts of nano-zinc oxide, 0.5 parts of additives, 20 parts of curing agent and 15 parts of Parts of non-reactive diluent, weigh appropriate amount of raw materials for each component;

[0041] Among them, the epoxy resin is: E-51 bisphenol A epoxy resin, the reactive diluent is: allyl glycidyl ether; the additives are: wetting and dispersing agent AT-203, leveling agent BYK-354 and defoamer Silicone defoamer, wherein the mass ratio of wetting dispersant, leveling agent and defoamer is 1:1:1; the curing agent is: cashew nut shell epoxy curing agent; the non-reactive diluent is: xylene A mixed solution with petroleum ether, wherein the volume ratio of xylene to petroleum ether is 1:2.

[0042] Then, prepare the anticorrosion coating according to the following steps:

[0043] (1) At room temperature, add epoxy res...

Embodiment 2

[0048] According to the mass fraction: 50 parts of bisphenol A epoxy resin, 10 parts of reactive diluent, 15 parts of titanium dioxide, 8 parts of barium sulfate, 15 parts of red iron oxide, 5 parts of nano-zinc oxide, 1 part of auxiliary agent, 30 parts of curing agent And 25 parts of non-reactive diluents, weigh appropriate amount of raw materials of each component respectively;

[0049] Among them, the epoxy resin is: E-44 epoxy resin; the reactive diluent is: butyl glycidyl ether; the additives are: wetting and dispersing agent AT-203, leveling agent BYK-354 and defoaming agent silicone defoaming Among them, the mass ratio of wetting and dispersing agent, leveling agent and defoaming agent is 1:2:1; the curing agent is: polyamide curing agent; the non-reactive diluent is: mixed solution of xylene and petroleum ether , wherein the volume ratio of xylene to petroleum ether in milliliters is 1:1.

[0050] Then, prepare the anticorrosion coating according to the following ste...

Embodiment 3

[0056] In parts by mass: 40 parts of epoxy resin, 8 parts of reactive diluent, 12 parts of titanium dioxide, 6 parts of barium sulfate, 10 parts of red iron oxide, 3 parts of nano-zinc oxide, 0.8 parts of auxiliary agent, 25 parts of curing agent and 20 parts of Parts of non-reactive diluent, weigh an appropriate amount of each raw material component;

[0057] Among them, the epoxy resin is E-42 bisphenol A epoxy resin; the reactive diluent is: dimethyl glycidyl ether; the additives are: wetting and dispersing agent AT-203, leveling agent BYK-354 and defoamer organic Silicon defoamer, wherein, the mass ratio of wetting dispersant, leveling agent and defoamer is 1:2:2; the curing agent is: cashew nut shell epoxy curing agent; the non-reactive diluent is: xylene and A mixed solution of petroleum ether, wherein the volume ratio of xylene to petroleum ether in milliliters is 2:3.

[0058] Then, according to the method described in Example 2, the anticorrosion coating of Example 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com