Biodegradable flowerpot material and preparation method thereof

A biodegradation and flowerpot technology, applied in the field of material engineering, can solve problems such as environmental pollution and resource waste, achieve the effect of simple production process, avoid environmental damage, and achieve high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Adopt the raw material of following quality powder to produce distiller's grains / polylactic acid composite material (the flower pot material that can be biodegradable utilization): 100 parts of polylactic acid, 20 parts of distiller's grains, 20 parts of tributyl citrate, 0.2 part of silane coupling agent; Production Proceed as follows:

[0040] 1) Dry the distiller's grains in a constant temperature oven at 60°C for 24 hours, then crush them to 50-100 mesh, and then place them in a constant temperature oven at 60°C for 2 hours to obtain distiller's grains powder;

[0041] 2) Put distiller's grains powder, polylactic acid, tributyl citrate and silane coupling agent as raw materials into a high-mixer and mix for 8 minutes to disperse them evenly to obtain a distiller's grains / polylactic acid mixture;

[0042] 3) The distiller's grain / polylactic acid mixture was extruded and granulated by a twin-screw extruder at a speed of 120 r / s at 180°C to obtain a distiller's grain / p...

Embodiment 2 6

[0044] The production process of embodiment two to six and processing parameter are identical with embodiment one, and difference is that the consumption of raw material is different, see table 1 for details:

[0045] The raw material consumption table of table 1 embodiment two to six

[0046]

Embodiment 7

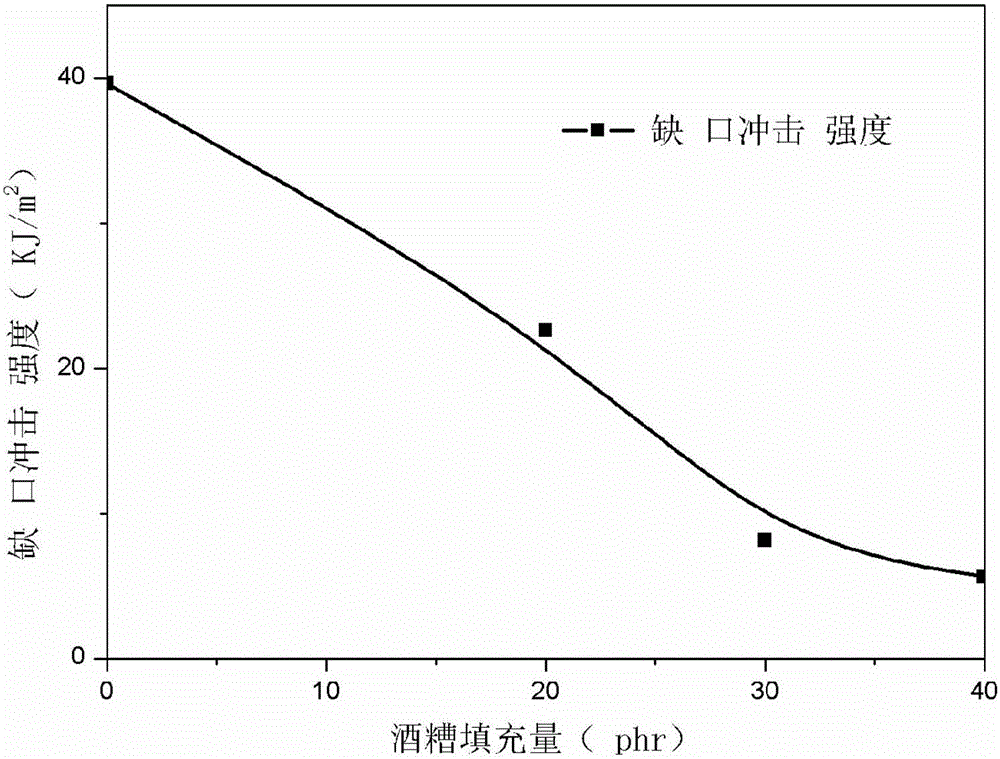

[0048] Take the distiller's grains / polylactic acid composite material produced in Examples 1 to 6 (i.e., the flowerpot material for biodegradation), and place them in a constant temperature oven at 60°C for 4 hours to dry the pellets completely; then dry the pellets The materials were injection-molded with an injection molding machine under appropriate process conditions to obtain samples and processed into six types of samples for performance testing. Among them, the process parameters of the injection molding machine are shown in Table 2. The tensile strength test is carried out with an electronic universal tensile machine, which implements the standard GB / T 1040.2-2006; Cut A-type 2mm gap, sample size 80mm×10mm×4mm, refer to GB / T1843-1996.

[0049] Table 1 Injection molding process parameters

[0050]

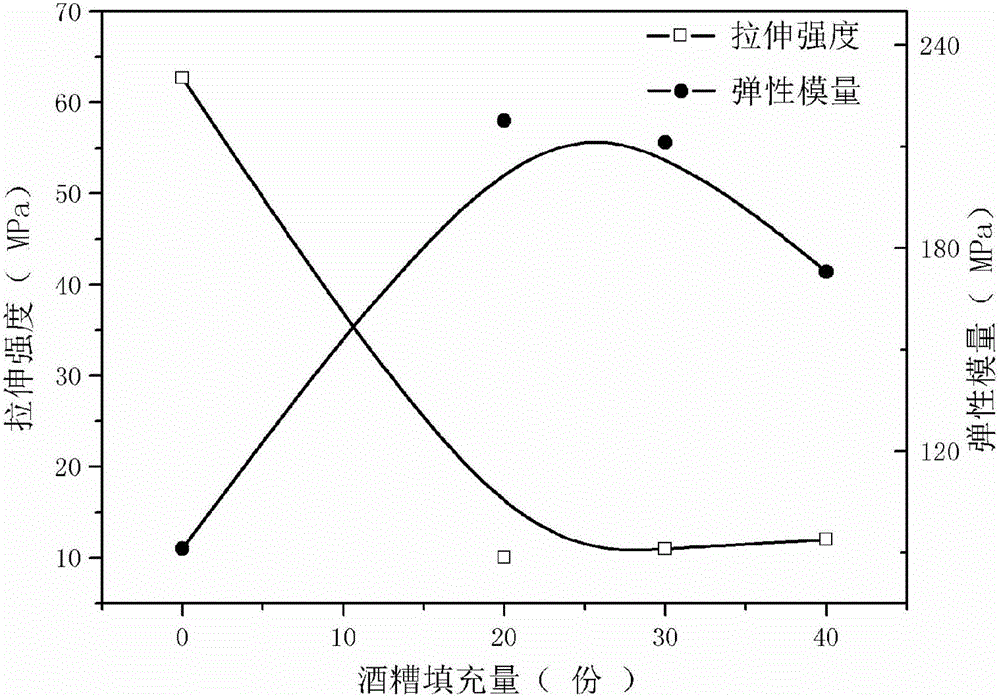

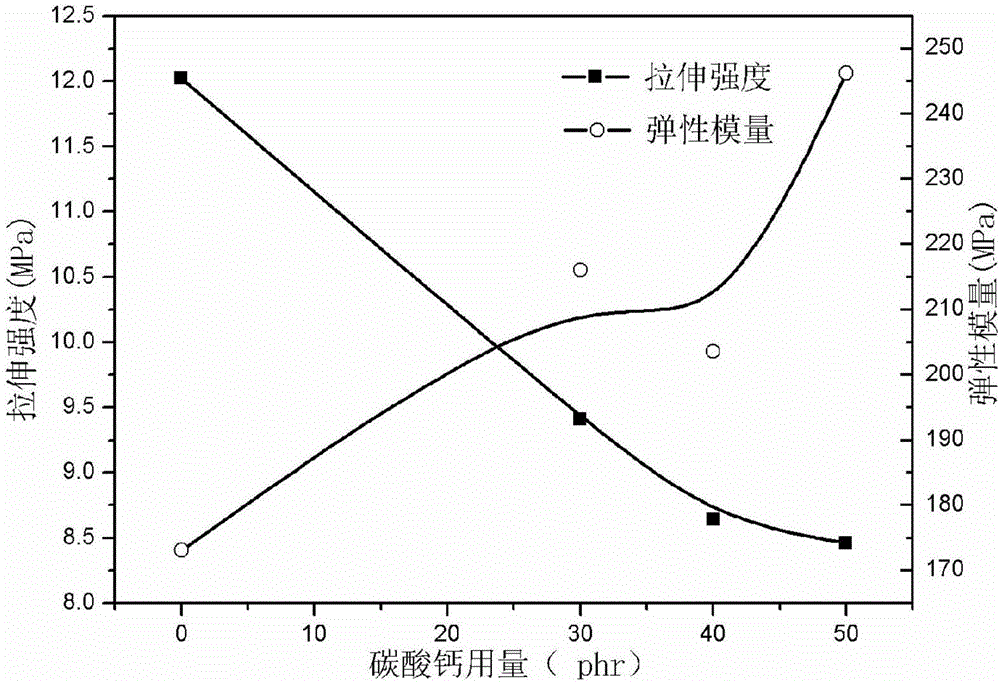

[0051] 1. Tensile strength test

[0052] Process the six types of samples obtained by injection molding into splines (initial gauge length 110mm, width 10mm, thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com