Cover film and electronic component package using same

A technology of covering film and heat-sealing layer, which is applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of insufficient stability of peel strength and achieve the effect of excellent transparency and not easy to break the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

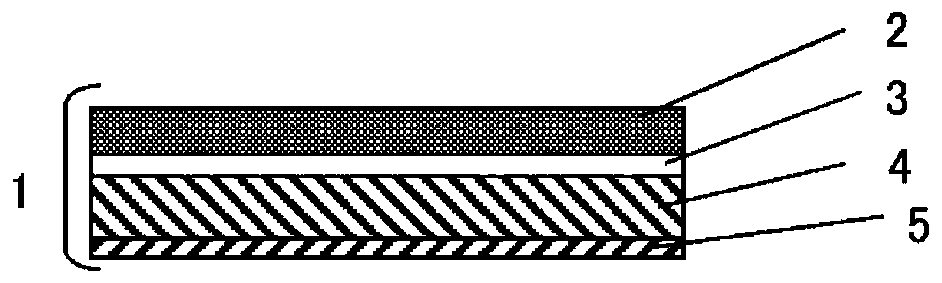

Image

Examples

Embodiment 1

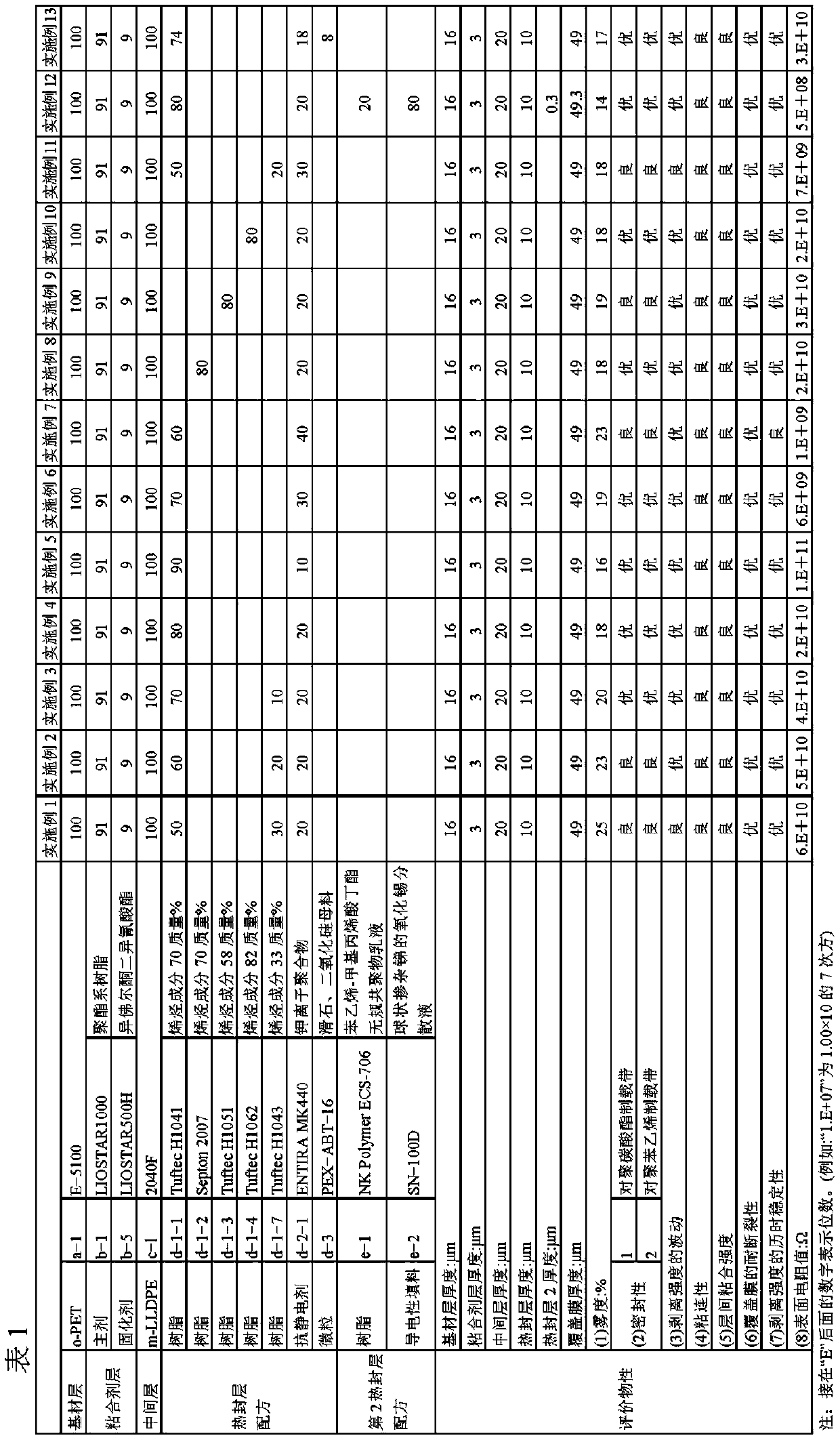

[0117] Using a rotating drum, the styrene-butadiene-styrene triblock copolymer hydrogenated resin (manufactured by Asahi Kasei Chemical Co., Ltd., "Tuftec H1041", olefin component) as the resin constituting the sealant layer (heat seal layer) Amount 70% by mass) 50% by mass and a hydrogenated resin of a triblock copolymer of styrene-butadiene-styrene (manufactured by Asahi Kasei Chemical Co., Ltd., "Tuftec H1043", olefin content 33% by mass) 30% by mass and Potassium ion polymer (manufactured by Mitsui DuPont Co., Ltd., "MK440") 20% by mass was pre-blended, and kneaded at 200°C using a single-screw extruder with a diameter of 40 mm, and obtained at a linear speed of 20 m per minute The resin composition constituting the sealant layer. The resin composition and the metallocene-based linear low-density polyethylene (Ube Maruzen Polyethylene Co., Ltd.) as the olefin-based resin constituting (C) the intermediate layer described in Tables 1 and 2 were extruded from respective uniaxi...

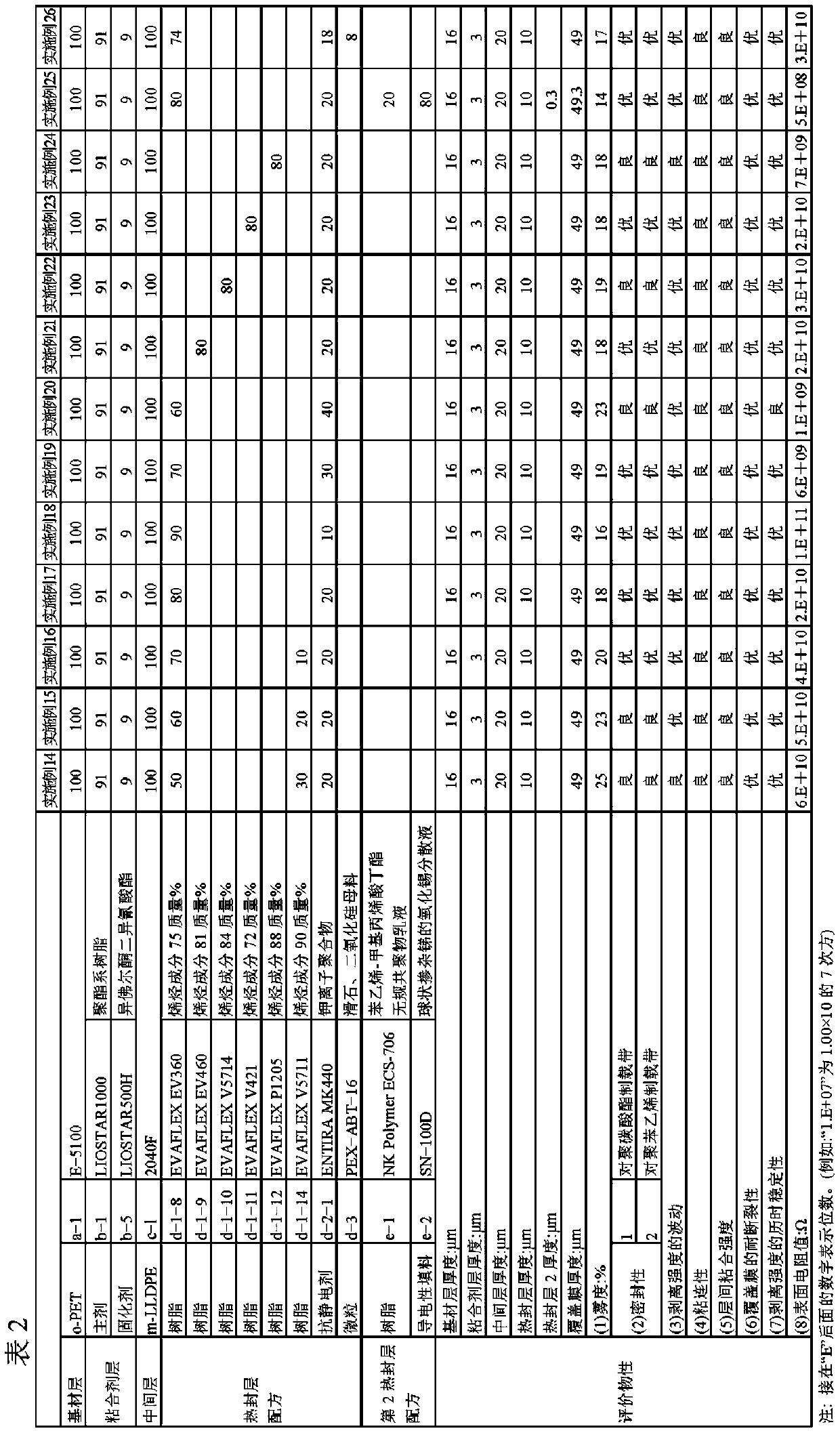

Embodiment 2~11、 Embodiment 13~24、 Embodiment 26~40

[0118] (Examples 2-11, Examples 13-24, Examples 26-40, Comparative Examples 1-22)

[0119] Except for forming the adhesive layer and the heat-sealing layer using raw materials such as resins described in Tables 1 to 5, the same procedure as in Example 1 was carried out to produce a cover film.

Embodiment 12

[0121] By using the laminated film obtained in Example 4, after corona treatment is performed on the surface of the (D) heat-seal layer, it is coated with 20% by mass of styrene-methacrylic acid so that the thickness after drying becomes 0.3 μm. The random copolymer of butyl ester [(e-1) resin] contains 80% by mass of a solution of [(e-2) conductive filler] to obtain a cover film for carrier tape having conductive properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com