Composite armoring structure and optical fiber cable

A composite structure, fiber optic cable technology, applied in the direction of fiber mechanical structure, active material electrode, etc., can solve the problems of inconvenient stripping, installation or maintenance efficiency reduction, etc., to achieve the effect of easy stripping, stable stripping strength, and convenient separation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

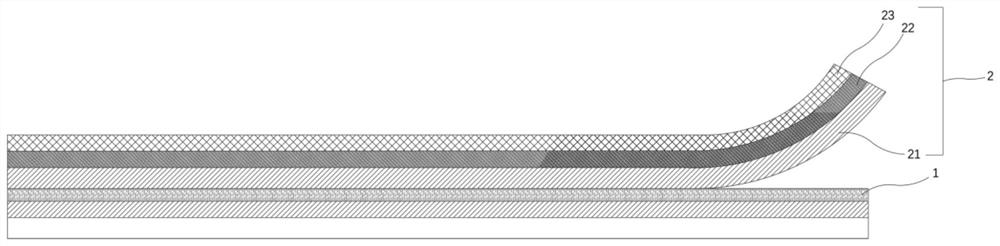

[0036] like figure 1 As shown, the present invention provides a composite armor structure, comprising a steel base strip 1, wherein one side of the steel base strip 1 has a composite structure 2, the composite structure 2 is convenient to install or connect with the outer sheath layer 3 of the optical fiber cable; In another preferred embodiment of the present invention, the other side of the steel base tape 1 has the same composite structure 2 for easy installation or connection with the filling layer 41 of the optical fiber tube core 4 or the inner sheath layer 5 .

[0037] The composite structure 2 includes a first layer of film 21, a second layer of film 22 and a third layer of film 33, wherein the first layer of film 21 and the steel base belt 1 are bonded by electromagnetic compounding, and the electromagnetic compounding is an electromagnetic heating system. A heating method from the inside to the outside. When heating the substrate, the heating source will not directly...

Embodiment 2

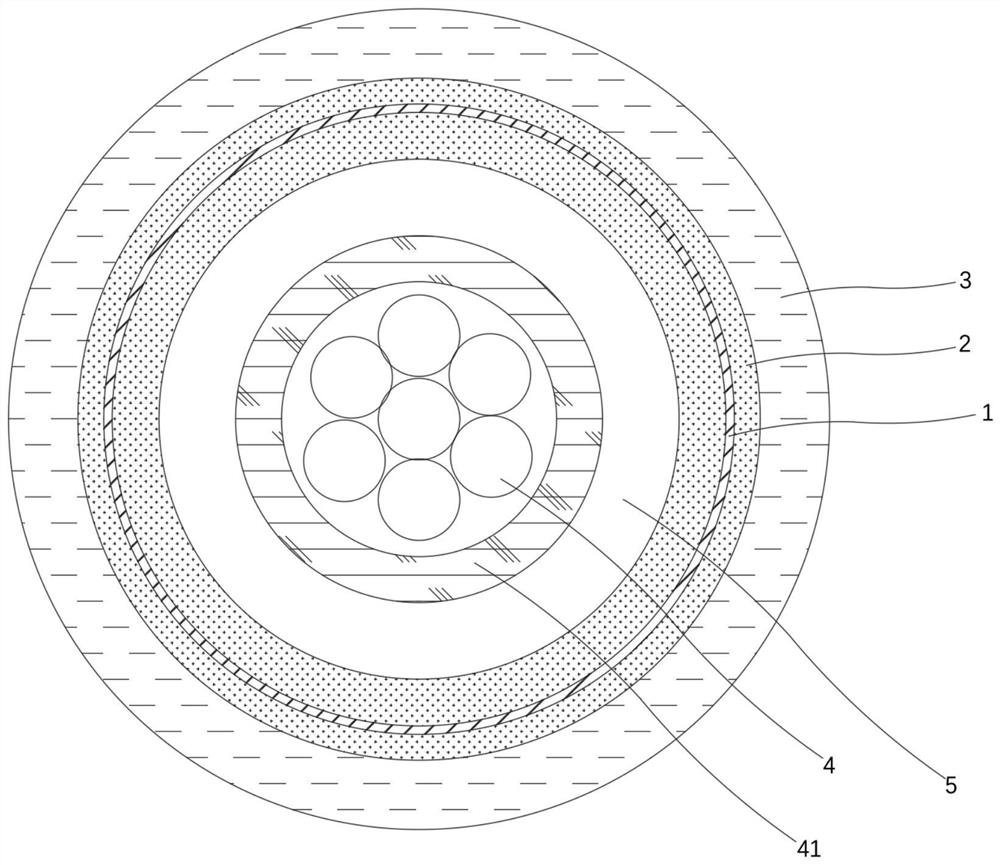

[0043] like figure 2 As shown, the present invention provides a kind of optical fiber cable, has the composite armor structure in embodiment 1, wherein, the composite armor structure is sleeved in the outer sheath layer 3, and the inner layer of the composite armor structure is sleeved with an optical fiber tube Core 4, the outer layer of the optical fiber tube core 4 is sleeved with a filling layer 41, in this embodiment, the filling layer 41 is between the optical fiber tube core 4 and the steel base tape 1 of the composite armor structure (the steel base tape 1 has only one side When there is a composite structure 2), or the filling layer 41 is between the fiber tube core 4 and the third layer of film 23 of the composite armor structure (when both sides of the steel base tape 1 have a symmetrical composite structure 2), the fiber tube protection of the core, while the peeling strength of the second layer of film 22 and the third layer of film 23 of the composite structure ...

Embodiment 3

[0046] The composite armor structure in Example 1 is used to make the pole plate of lithium battery or hydrogen battery. When it is applied to lithium battery, due to the metal characteristics of polymer material and base material, when the metal base material is immersed in acidic solution, the metal base material The material will generate positive ions. Since the composite material is a multi-layer polymer material, a negative polarity is formed, and a closed electric field is generated between the metal base material and the polymer material, forming a new type of polar battery structure. This material ( Composite armored structure) is used as a battery multi-level board, which has the characteristics of small size, simple structure, multiple groups can be used in parallel, and long service life.

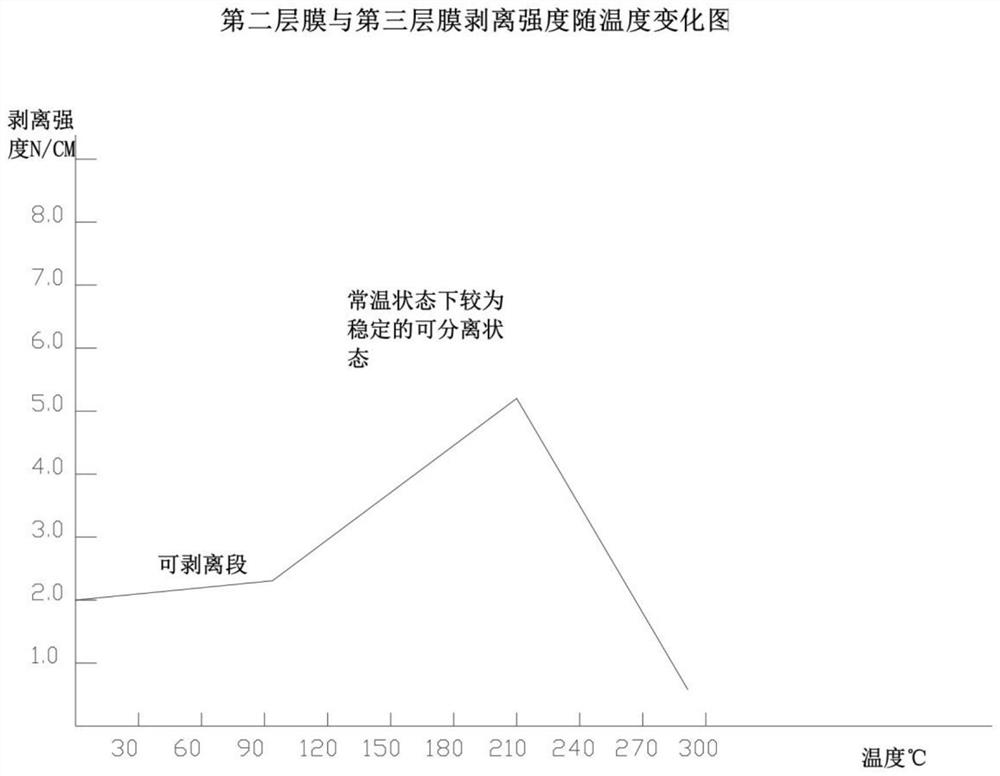

[0047] The peeling strength of the second layer of film 22 and the third layer of film 23 of the composite armor structure of the present invention is relatively stable, convenie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com