Organosilicon-modified cationic aqueous polyurethane paper wet strength agent and preparation method

A water-based polyurethane, cationic technology, applied in the field of chemistry, can solve the problems of poor emulsion storage stability and mechanical properties of coating films, damage to mechanical properties of materials, low surface energy, etc., to avoid free formaldehyde and organic halides, improve mechanical properties. Good performance and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

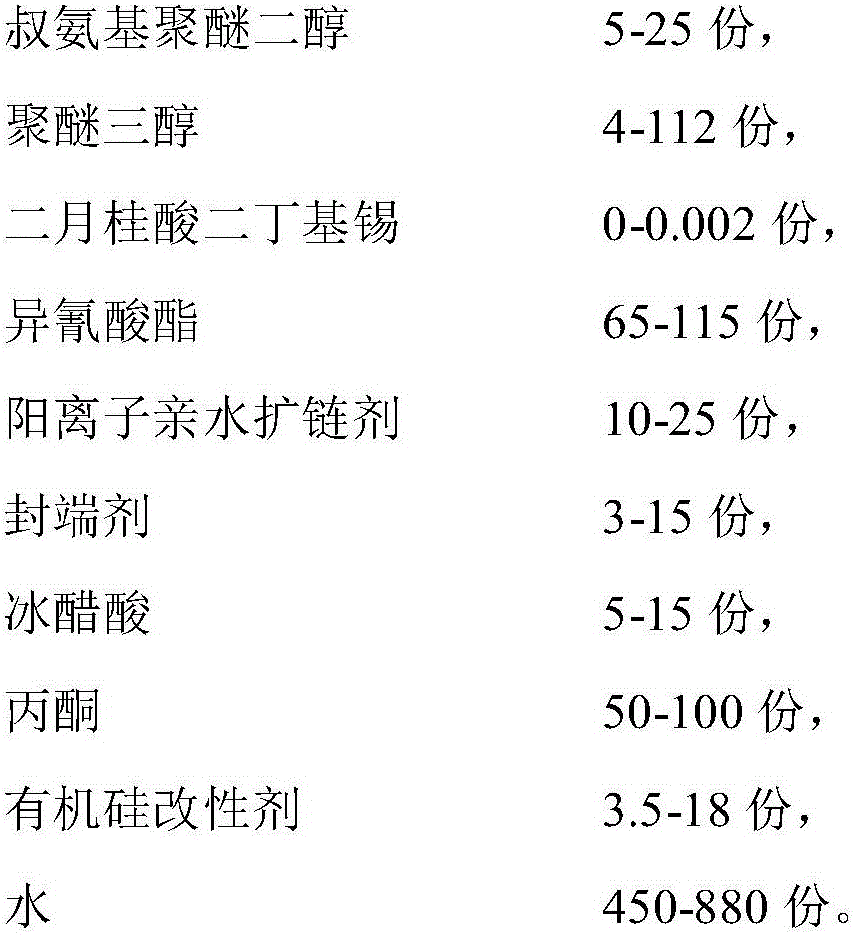

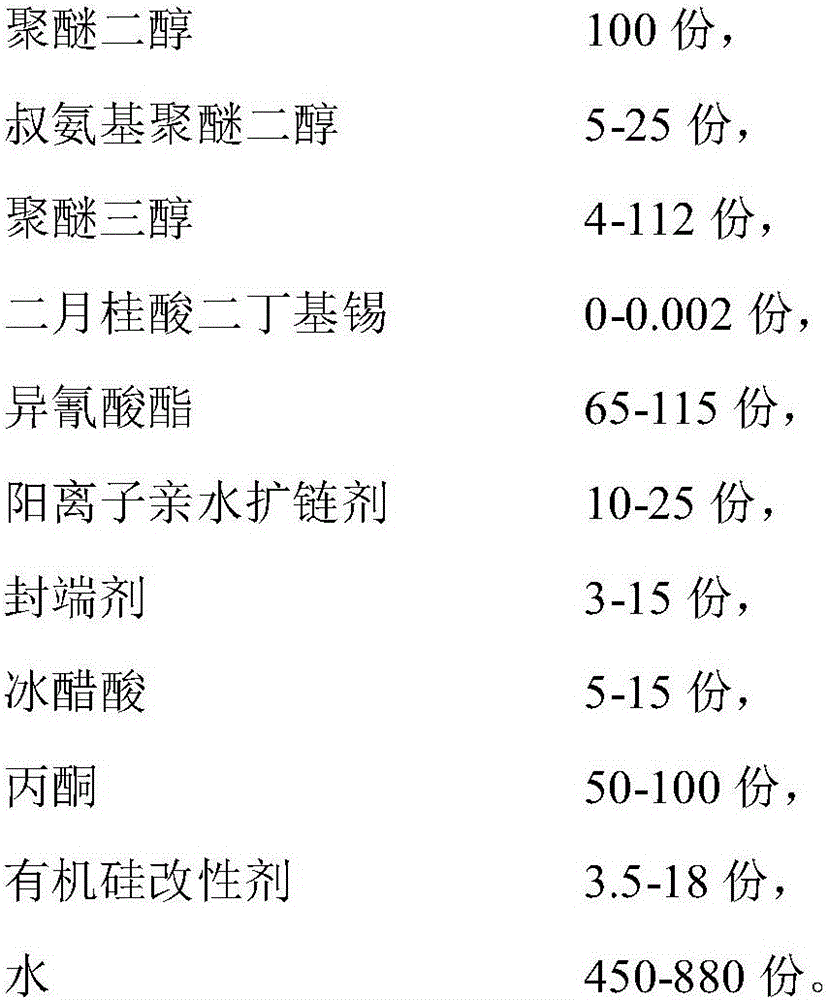

Method used

Image

Examples

Embodiment 1

[0031] A silicone-modified cationic water-based polyurethane paper wet strength agent, prepared by the following method:

[0032] S1. Add 11.1 g of tertiary amino polyoxyethylene diol, 100 g of polytetrahydrofuran diol, and 49.3 g of polyoxypropylene triol with a number-average molecular weight of 1000 after vacuum dehydration to a four-necked bottle equipped with a reflux condenser In the middle, stir, heat up, and when the temperature rises to 65-80°C, add 0.001g of dibutyltin dilaurate, 102.8g of isophorone diisocyanate and 37ml of acetone, and react for 2-3h;

[0033] S2. Cool down to 40°C, add 22.1g of N,N-dimethyldiethanolamine, control the appropriate dropping rate, add 18ml of acetone to reduce the viscosity, and extend the chain reaction for 2-3h;

[0034] S3. Then add 3.2 g of methyl ethyl ketone oxime and react for 2-3 hours, then add 11.8 g of glacial acetic acid to form a quaternary ammonium salt cation, and complete the reaction to obtain a polyurethane prepolyme...

Embodiment 2

[0037] A silicone-modified cationic water-based polyurethane paper wet strength agent, prepared according to the method described in Example 1, including the following raw materials: tertiary amino polyoxyethylene glycol 5g, polytetrahydrofuran glycol 100g, polyoxypropylene triol 46.7 g, 93.4g of isophorone diisocyanate, 20.9g of N,N-dimethyldiethanolamine, 3.1g of methyl ethyl ketoxime, 10.8g of glacial acetic acid, 662.9g of deionized water, N-(β-aminoethyl)-γ - Aminopropylmethyldimethoxysilane 15.3 g.

Embodiment 3

[0039] A silicone-modified cationic water-based polyurethane paper wet strength agent, prepared according to the method described in Example 1, including the following raw materials: tertiary amino polyoxyethylene glycol 25g, polytetrahydrofuran glycol 100g, polyoxypropylene triol 55.4 g, 115g of isophorone diisocyanate, 25g of N,N-dimethyldiethanolamine, 3.5g of methyl ethyl ketoxime, 15g of glacial acetic acid, 800g of deionized water, N-(β-aminoethyl)-γ-aminopropyl Methyldimethoxysilane 18g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com