Cationic surfactant and application thereof

A surfactant, cationic technology, used in liquid separation, separation methods, grease/oily substances/floating matter removal devices, etc. and other problems, to achieve the effect of small molecular weight, long storage period and low free formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

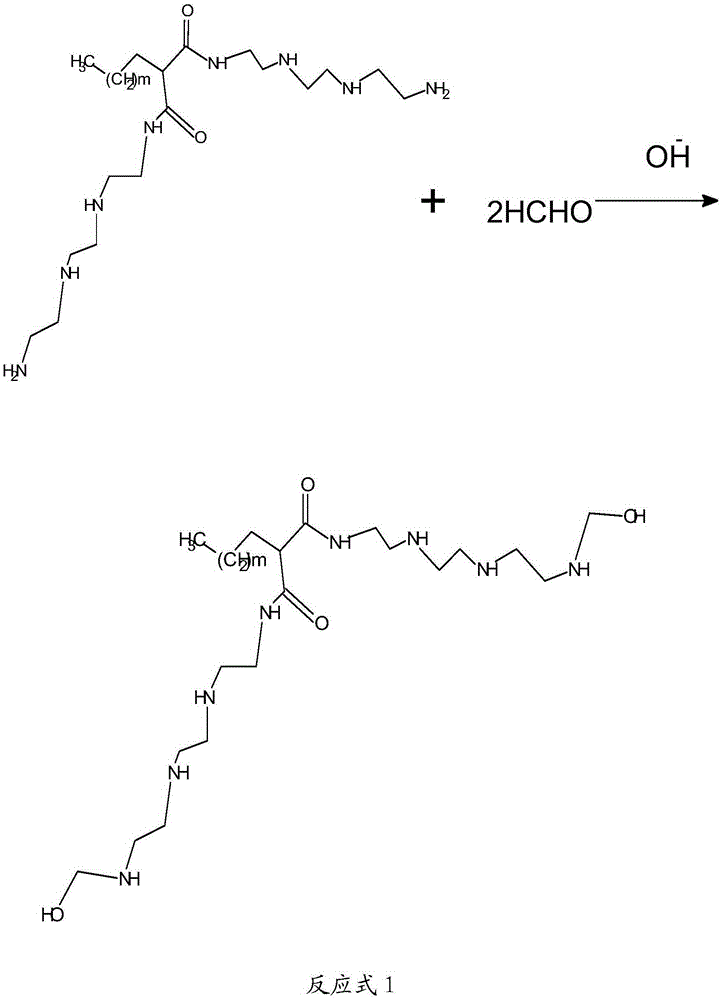

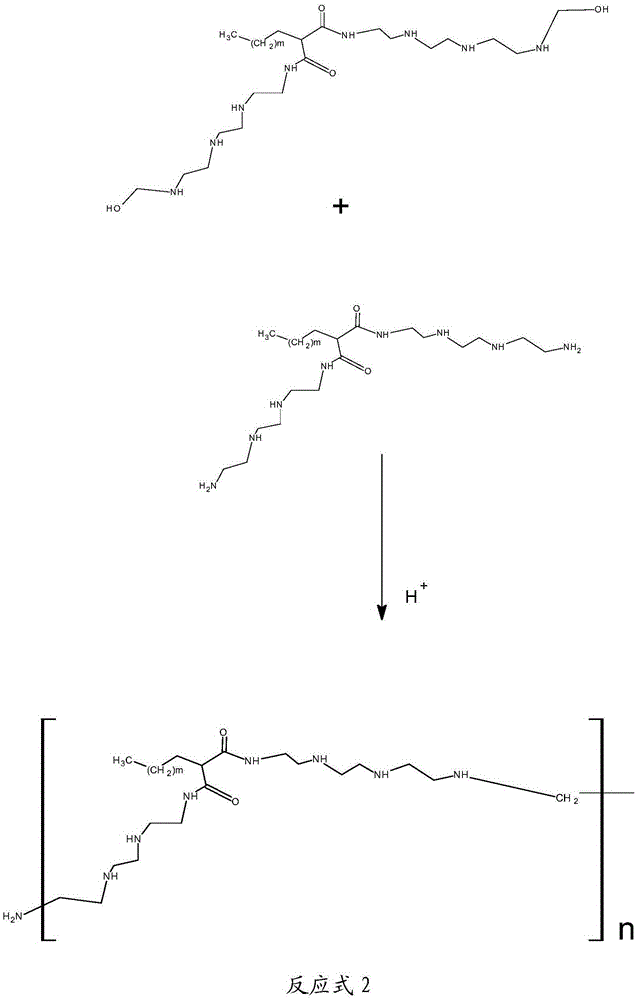

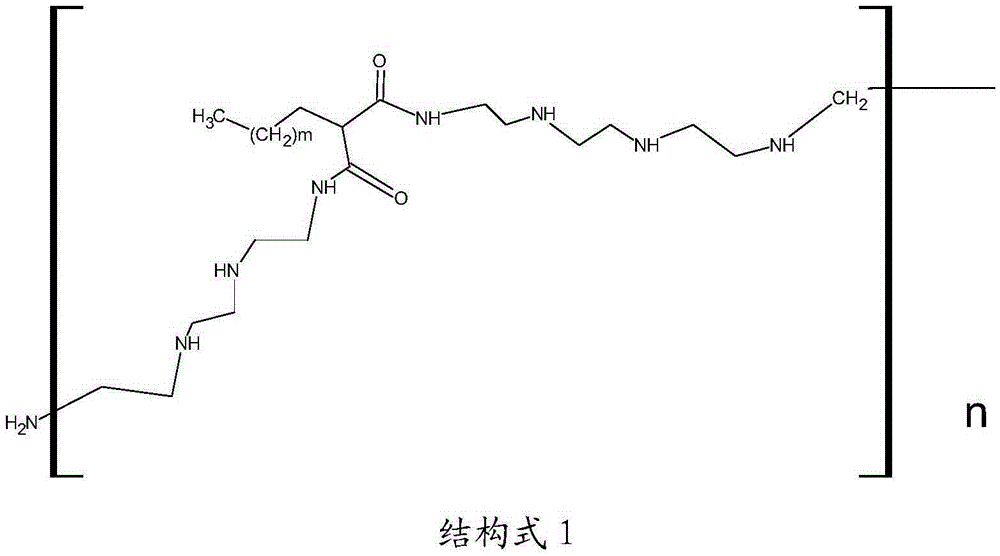

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a cationic surfactant, which is prepared through three process steps of metering and mixing, methylol reaction, and polycondensation reaction, as follows: add 400 parts by weight of water to the reaction kettle, and heat up to 60°C , adjust the pH to 9 with an alkaline substance; then add 40 parts by weight of an alkylamide polyamine cationic surfactant, add 70 parts by weight of formaldehyde, heat up to 80°C, and react for 40 minutes; adjust the pH to 2 with an acidic substance, Raise the temperature and react at 85°C for 4 hours; keep warm for 30 minutes to obtain the cationic surfactant.

[0029] The cationic surfactant prepared in this example has a cationic degree of 30% (the cationic degree is tested by colloid titration), a density of 0.98 g / ml, and an effective storage period of more than 1 year.

Embodiment 2

[0031] A method for preparing a cationic surfactant, which is prepared through three process steps of metering and mixing, methylol reaction, and polycondensation reaction, as follows: add 800 parts by weight of water to the reaction kettle, and heat up to 65°C , adjust the pH to 9.5 with an alkaline substance; then add 120 parts by weight of an alkyl amidopolyamine cationic surfactant, add 240 parts by weight of formaldehyde, heat up to 85 ° C, and react for 60 minutes; adjust the pH to 4 with an acidic substance, Raise the temperature, react at 95° C. for 2 hours, and keep warm for 30 minutes to obtain a cationic surfactant.

[0032] The cationic surfactant prepared in this example has a cationic degree of 32%, a density of 1.01 g / ml, and an effective storage period of more than 1 year.

Embodiment 3

[0034] A method for preparing a cationic surfactant, which is prepared through three process steps of metering and mixing, methylol reaction, and polycondensation reaction, as follows: add 900 parts by weight of water to the reaction kettle, and heat up to 65°C , adjust the pH to 8.5 with an alkaline substance; then add 60 parts by weight of an alkyl amido polyamine cationic surfactant, add 110 parts by weight of formaldehyde, heat up to 80-85 ° C, and react for 60 minutes; use an acidic substance to adjust the pH to 3. Raise the temperature and react at 90°C for 3 hours; keep warm for 60 minutes to obtain the cationic surfactant.

[0035] The cationic surfactant prepared in this example has a cationic degree of 32%; a density of 1.03 g / ml, and an effective storage period of more than 1 year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com