Metal-organic framework material for efficient CO2/N2 selective separation and adsorption and preparation method of metal-organic framework material

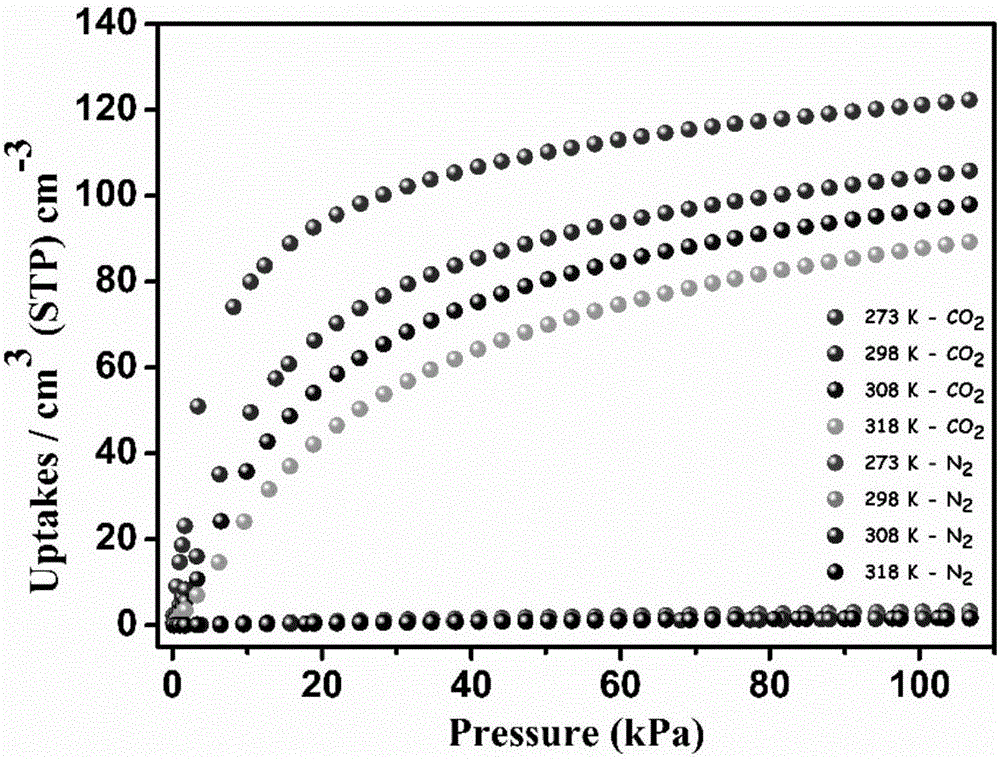

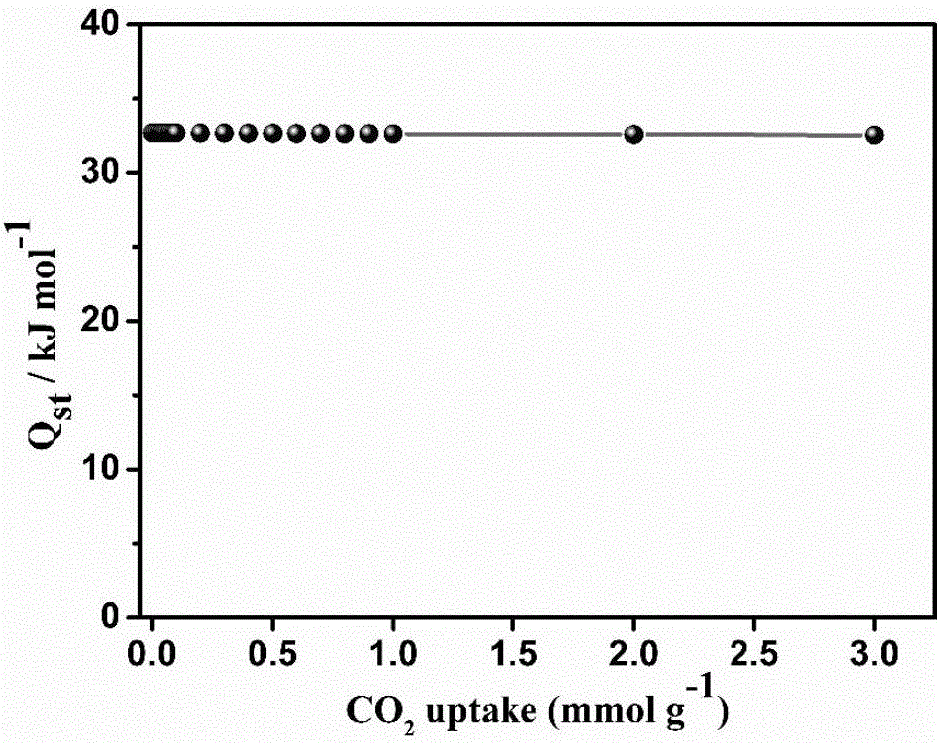

A metal-organic framework, high-efficiency technology, applied in separation methods, 2/12 organic compounds without C-metal bonds, chemical instruments and methods, etc., can solve high reuse costs, difficult aperture/window size adjustment, etc. problems, to achieve the effect of reducing the cost of repeated use, ultra-high selective separation and adsorption performance, and avoiding structure penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

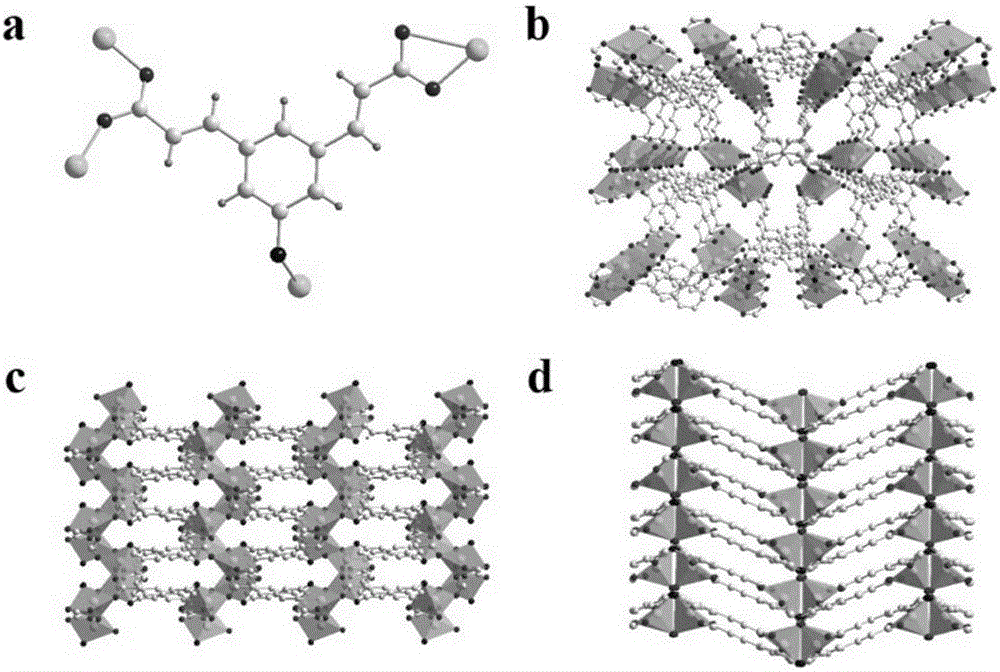

[0027] Example: (1) Using cross-coupling reaction, 11.87g, 40mmol of 3,5-dibromoaniline, 9mL, 100mmol of ethyl acrylate, 10.35g, 75mmol of anhydrous potassium carbonate, 3.22g, 10mmol of tetrabutyl Ammonium bromide and 1.122g, 5mmol of palladium acetate (catalyst) were uniformly dissolved in 100mL of DMF according to the set stoichiometric ratio, and reacted for 1 to 2 days under stirring conditions at 130°C, and were extracted by ethyl acetate and water multiple times. , dried over anhydrous magnesium sulfate, chromatographic purification and subsequent hydrolysis to obtain organic ligand 5-amino-1,3-benzenediacrylic acid with high chemical purity.

[0028] (2) Using solvothermal method, 8 mg, 0.014 mmol of organic ligand 5-amino-1,3-benzenediacrylic acid and 15.0 mg, 0.051 mmol of metal salt Zn(NO 3 ) 2 ·6H 2 O in solvent (DMF:H 2 O: acetonitrile, 2mL / 4mL / 7mL) was ultrasonically oscillated for five minutes until uniformly dissolved, and reacted at 80°C for 1 day to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com