A kind of winding preparation method of high porosity porous ceramic tube

A porous ceramic, high porosity technology, applied in ceramic products, ceramic molding machines, manufacturing tools, etc., can solve the problems of large compression deformation, low strength, application limitations, etc., and achieve the effect of low filtration pressure drop and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

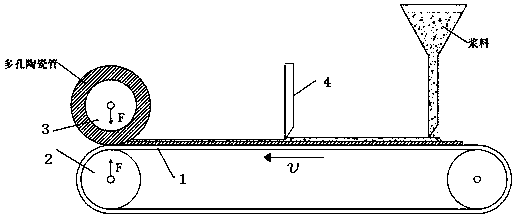

Image

Examples

Embodiment 1

[0020] The preparation method of the described high-porosity porous ceramic tube comprises the following steps:

[0021] a. Preparation of suspension: put 85 parts of deionized water into the mixer, start stirring, weigh 0.3 parts of ammonium polyacrylate, 2 parts of aluminum silicate polycrystalline fiber with fiber length ≥ 40 mm, and 3 parts of 10% PVA solution, 10 parts of silica sol, and added in order at intervals of 1.0min, mixed evenly to make a slurry suspension;

[0022] b. Fibrous film forming: pass the first water-based slurry evenly through a 30-mesh stainless steel screen, so that the aluminum silicate polycrystalline fiber is evenly spread on the surface of the screen, forming a two-dimensionally stretched aluminum silicate polycrystalline fiber film. Remove the film from the sieve, place it on a flat plate, and flatten it with a winding drum to obtain a film with a thickness of 2.3mm, and dry it at room temperature at 50°C for 5 hours;

[0023] c. Preparation ...

Embodiment 2

[0028] The preparation method of the described high-porosity porous ceramic tube comprises the following steps:

[0029] a. Preparation of suspension: put 80 parts of deionized water into the mixer, start stirring, weigh 0.4 parts of ammonium polyacrylate, 0.5 parts of aluminum silicate polycrystalline fiber with fiber length ≥ 20 mm, and 4 parts of 10% PVA solution, 15 parts of aluminum sol, and added sequentially at intervals of 1.0 min, mixed evenly to make a slurry suspension;

[0030] b. Fibrous film formation: pass the first water-based slurry evenly through a 40-mesh stainless steel screen, so that the aluminum silicate polycrystalline fiber is evenly spread on the surface of the screen to form a two-dimensionally stretched aluminum silicate polycrystalline fiber film. Remove the film from the sieve, place it on a flat plate and flatten it with a winding drum to obtain a film with a thickness of 0.7mm, and dry it at room temperature at 60°C for 1 hour;

[0031] c. Prep...

Embodiment 3

[0036] The preparation method of the described high-porosity porous ceramic tube comprises the following steps:

[0037] a. Preparation of the suspension: Put 78 parts of deionized water into the mixer, start stirring, weigh 0.4 parts of ammonium polyacrylate, 1.5 parts of aluminum silicate polycrystalline fiber with a fiber length ≥ 30 mm, and 2 parts of 10% PVA solution. 18 parts of aluminum sol, and added sequentially at intervals of 1.0min, mixed evenly to make a slurry suspension

[0038]b. Fibrous film formation: pass the first water-based slurry evenly through a 30-mesh stainless steel screen, so that the aluminum silicate polycrystalline fiber is evenly spread on the surface of the screen, forming an aluminum silicate polycrystalline fiber film stretched in the two-dimensional direction. Remove the film from the sieve, place it on a flat plate, and flatten it with a winding drum to obtain a film with a thickness of 1.5mm, and dry it at room temperature at 60°C for 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com