Anti-corrosion high strength-to-yield ratio earthquake-resistant reinforced bar and production method thereof

A technology of anti-seismic steel bars and production methods, which is applied in the fields of iron and steel metallurgy and steel rolling, can solve problems such as high cost, difficulty in achieving corrosion resistance, application promotion, and economic losses, and achieve excellent anti-seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

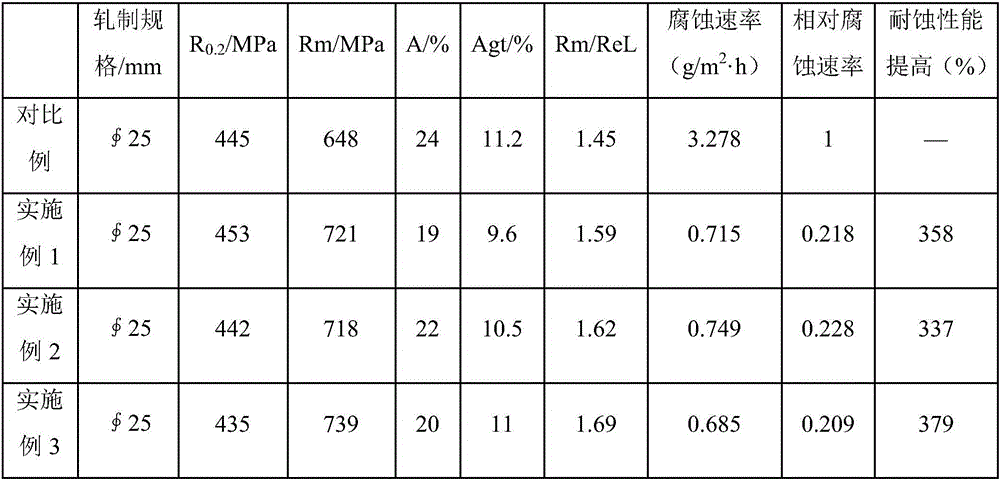

Examples

Embodiment 1

[0027] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0028] After pre-desulfurization of molten iron, molten iron, scrap steel, etc. are added to the converter, and then top-bottom double blowing smelting is carried out until the carbon content in the molten steel is less than 0.05%, and the phosphorus content is less than 0.01%. Si and Mn alloying elements are used for alloy deoxidation, adding carbon powder and slagging material; refining and deoxidizing in LF furnace until the oxygen content in molten steel is 0.002% to 0.005%; after deoxidizing, adding other alloying elements for alloying and sending to RH for refining. Protective pouring is used during billet continuous casting to prevent breakout. The continuous casting slab is heated in the heating furnace at a temperature of 1080°C, and the starting rolling temperature is 960°C. After 6 rough rolling stands and 6 intermediate rolling stands, a per...

Embodiment 2

[0030] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0031]After pre-desulfurization of molten iron, molten iron, scrap steel, etc. are added to the converter, followed by top-bottom double blowing smelting, smelting until the carbon content in the molten steel is less than 0.05%, and the phosphorus content is less than 0.01%. Si and Mn alloying elements are used for alloy deoxidation, adding carbon powder and slagging material; refining and deoxidizing in LF furnace until the oxygen content in molten steel is 0.002% to 0.005%; after deoxidizing, adding other alloying elements for alloying and sending to RH for refining. Protective pouring is used during billet continuous casting to prevent breakout. The continuous casting slab is heated at a heating temperature of 1060°C in a heating furnace, and the starting rolling temperature is 940°C. After 6 rough rolling stands and 6 intermediate rolling stands, a ...

Embodiment 3

[0033] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0034] After pre-desulfurization of molten iron, molten iron, scrap steel, etc. are added to the converter, followed by top-bottom double blowing smelting, smelting until the carbon content in the molten steel is less than 0.05%, and the phosphorus content is less than 0.01%. Si and Mn alloying elements are used for alloy deoxidation, adding carbon powder and slagging material; refining and deoxidizing in LF furnace until the oxygen content in molten steel is 0.002% to 0.005%; after deoxidizing, adding other alloying elements for alloying and sending to RH for refining. Protective pouring is used during billet continuous casting to prevent breakout. The continuous casting slab is heated at 1070°C in the heating furnace, and the starting rolling temperature is 940°C. After 6 rough rolling and 6 intermediate rolling, a section of water cooling is carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com