A kind of fly ash aluminum extraction residue/rubber composite material and preparation method thereof

A technology for extracting aluminum and composite materials from fly ash, which is applied in the field of polymer material processing, can solve the problems that rubber cannot play a reinforcing role, the particle size of aluminum-extracting residues from fly ash is coarse, and the vulcanization promotion effect is weakened, so as to improve the vulcanization effect. Delay effect, shorten vulcanization time, enhance the effect of interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

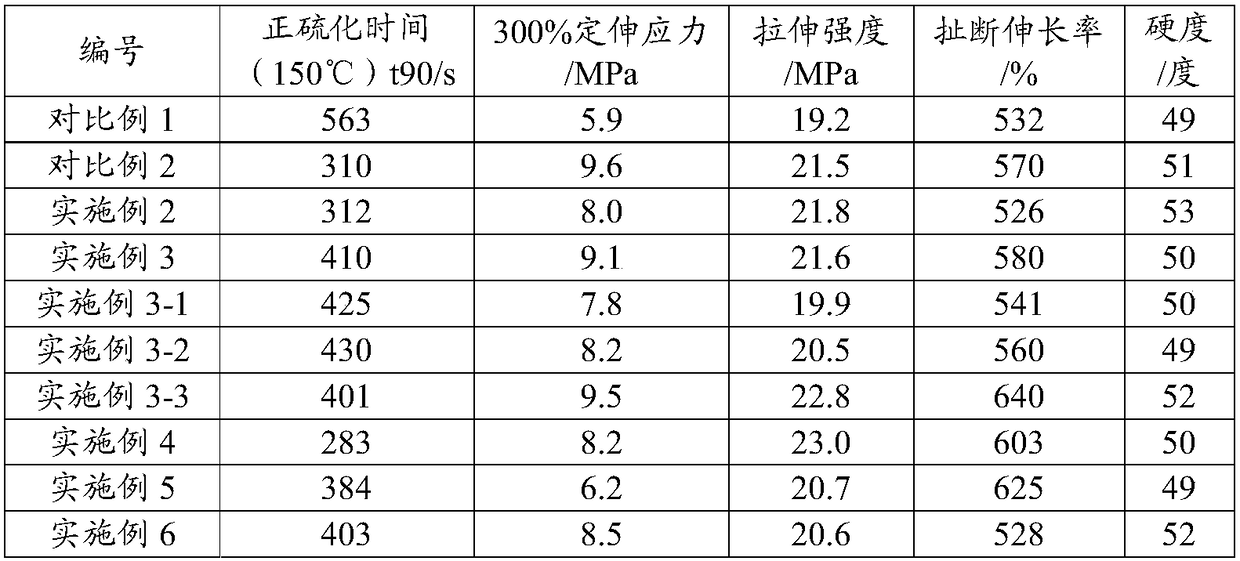

Examples

preparation example Construction

[0057] Raw material for the preparation of aluminum extraction residue from fly ash

[0058] The raw material for the preparation of aluminum extraction residue from fly ash is circulating fluidized bed pulverized coal produced by a thermal power plant, and its chemical composition is shown in Table 1.

[0059] Table 1 CFB fly ash chemical composition (wt%)

[0060] SiO 2

Embodiment 1

[0062] Get above-mentioned fluidized bed fly ash (table 1), be pulverized to 200 orders (Taylor standard sieve), add water and make the slurry that solid content is 33wt%, use vertical ring magnetic separator (referring to Chinese patent CN102145905A, and its The whole content is introduced into this paper), magnetically separated twice at a field strength of 15,000 GS, and obtained a filter cake with a solid content of 37.5wt% after press filtration by a plate and frame filter press; adding a concentration of 28wt% to the filter cake The industrial hydrochloric acid is used for acid dissolution reaction, the molar ratio of HCl in hydrochloric acid to alumina in fly ash is 6:1, the reaction temperature is 150°C, the reaction pressure is 0.6MPa, the reaction time is 2h, and the reaction product is separated from solid and liquid to obtain Fly ash acid slag G1.

[0063] Take the above-mentioned fly ash acid slag G1, wash it with water until the pH value is 6-7, filter it, place ...

Embodiment 2

[0065] raw material:

[0066] Rubber 100g, G2 (fly ash aluminum extraction residue) 60g that embodiment 1 makes, sulfur 2.0g, accelerator (accelerator CZ1.5g, accelerator D0.5g), active agent (stearic acid 2.0g, oxidation Zinc 6.0g), anti-aging agent (anti-aging agent 4010NA 2.0g), plasticizer (No. 13 machine oil 3.0g), modification additive (diethylene glycol 2.0g).

[0067] Preparation:

[0068] (1) Wet Grinding G2 to particle size D 90 It is 1.9 μm, and after drying, it is added to a disperser to disperse to obtain a powder of fly ash aluminum extraction residue;

[0069] (2) First, plasticize the rubber on an open rubber mixer, then add anti-aging agent, accelerator and active agent in order, and mix with rubber evenly, then add fly ash aluminum extraction residue powder, Mix the plasticizer and modifying additives evenly, add sulfur at last, after mixing evenly, pound the rubber and lower the tablet to obtain the mixed rubber;

[0070] (3) Cool the mixed rubber for 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com