Application of welan gum for increasing recovery ratio in ultrahigh temperature oil reservoir oil displacement

A high-temperature oil and recovery technology, applied in the fields of biotechnology and energy exploitation, can solve the problems of low conversion rate of welan gum, lack of systematic science in the use of oil-displacing agent, high cost, and achieve the effect of excellent rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The physical model oil displacement experiment of Welan gum provided by the present invention (see the summary of the invention for details).

[0042] The pore volume, porosity, permeability, original oil content and original oil saturation of each core in the experiment are shown in Table 1, where 1-x, 2-x, 3-x, etc. are the experimental groups, and x is the number of cores in parallel experiments.

[0043] Table 1 Basic parameters of experiment

[0044]

[0045] Table 2 Injection system and injection method

[0046] Core serial number temperature Welan Gum Concentration injection method injection volume 1-1 60℃ 0% continuous injection 2PV 1-2 60℃ 0.2% continuous injection 2PV 1-3 60℃ 0.3% continuous injection 2PV 2-1 90℃ 0% continuous injection 2PV 2-2 90℃ 0.2% continuous injection 2PV 2-3 90℃ 0.3% continuous injection 2PV 3-1 120℃ 0% continuous injection 2PV ...

Embodiment 2

[0054] The viscosity-temperature characteristic of Welan gum provided by the present invention.

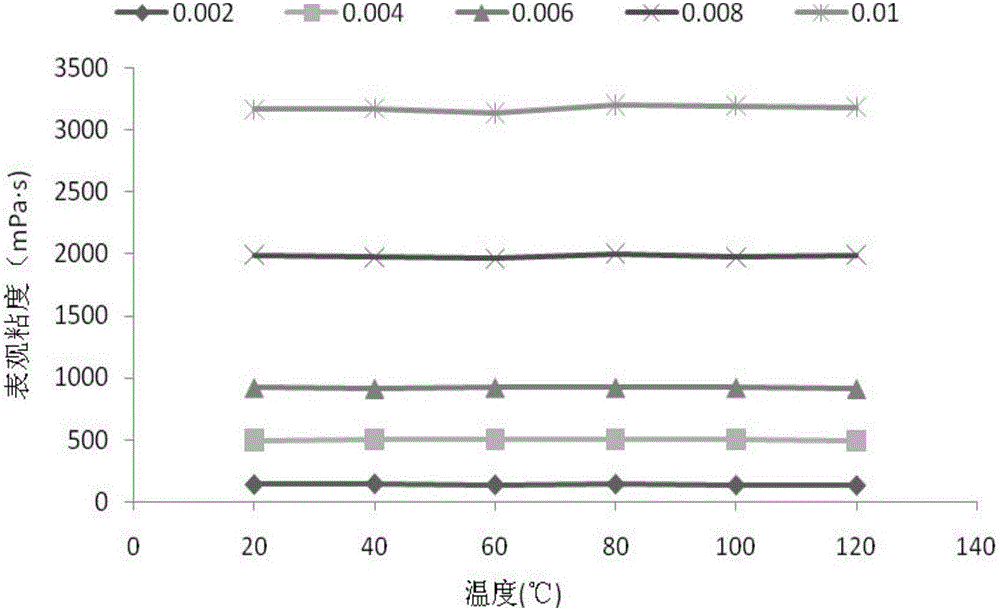

[0055] Prepare Welan gum aqueous solutions with concentrations of 0.2%, 0.4%, 0.6%, 0.8%, and 1.0%, respectively, and measure the viscosity of the solution with a DVLV-II rotary viscometer in the range of 20 to 120°C and at a constant speed of 60r / min. apparent viscosity ( figure 1 ). The viscosity of Welan gum solution with different concentrations changes very little at different temperatures, indicating that the Welan gum aqueous solution has good thermal stability, and its solution viscosity is basically not affected by temperature changes within the range of 20-120 °C.

Embodiment 3

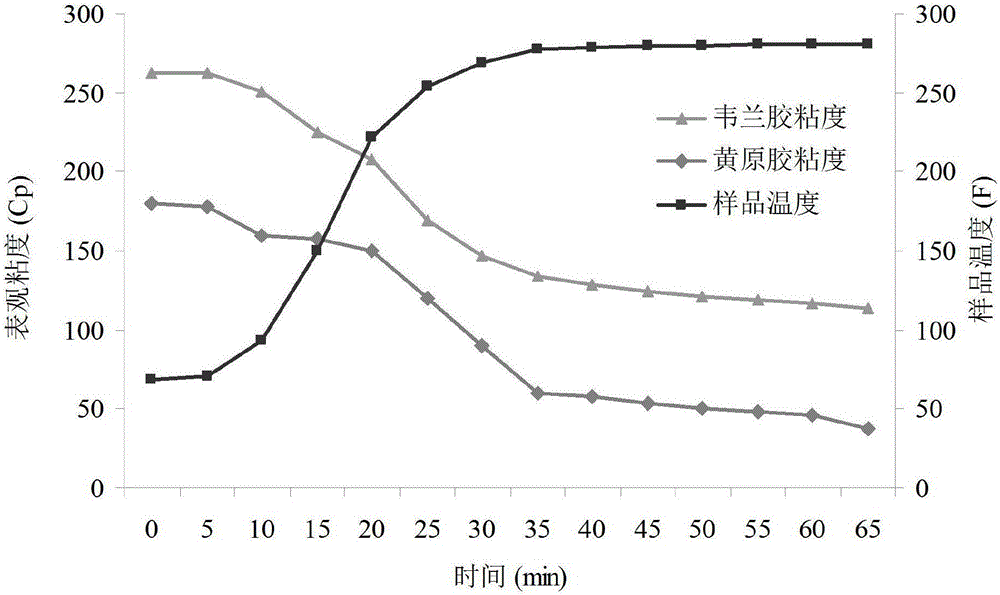

[0057] The temperature-resistant property of the welan gum provided by the invention.

[0058] Preparation concentration is the aqueous solution of 0.3% Welan gum, adds 23 sodium chloride, uses Fann 50SL high temperature and high pressure rheometer, measures pressure 756PST, under the temperature 138 ℃, when rotating speed is 60RPM, the change of the rheological properties of Welan gum ( figure 2 ). Although the viscosity of 1% Welan gum salt solution decreased, the final viscosity remained at 130mPa·s, which indicated that Welan gum could still maintain good rheological properties under high temperature and high pressure. In this experiment, the rheological change of 1% xanthan gum salt solution was measured with the same method. It can be seen that under the same conditions, the viscosity of xanthan gum salt solution is significantly lower than that of Welan gum. The viscosity of the solution drops significantly after 20-35 minutes of treatment, which shows that the rheolo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com