Composite passivation film for semiconductor device and preparation method thereof

A passivation film, semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of inconsistent thermal expansion coefficient, device surface composite enhancement, high surface state density, etc., to reduce Lattice defects, passivation of surface charges, and the effect of increasing operating junction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

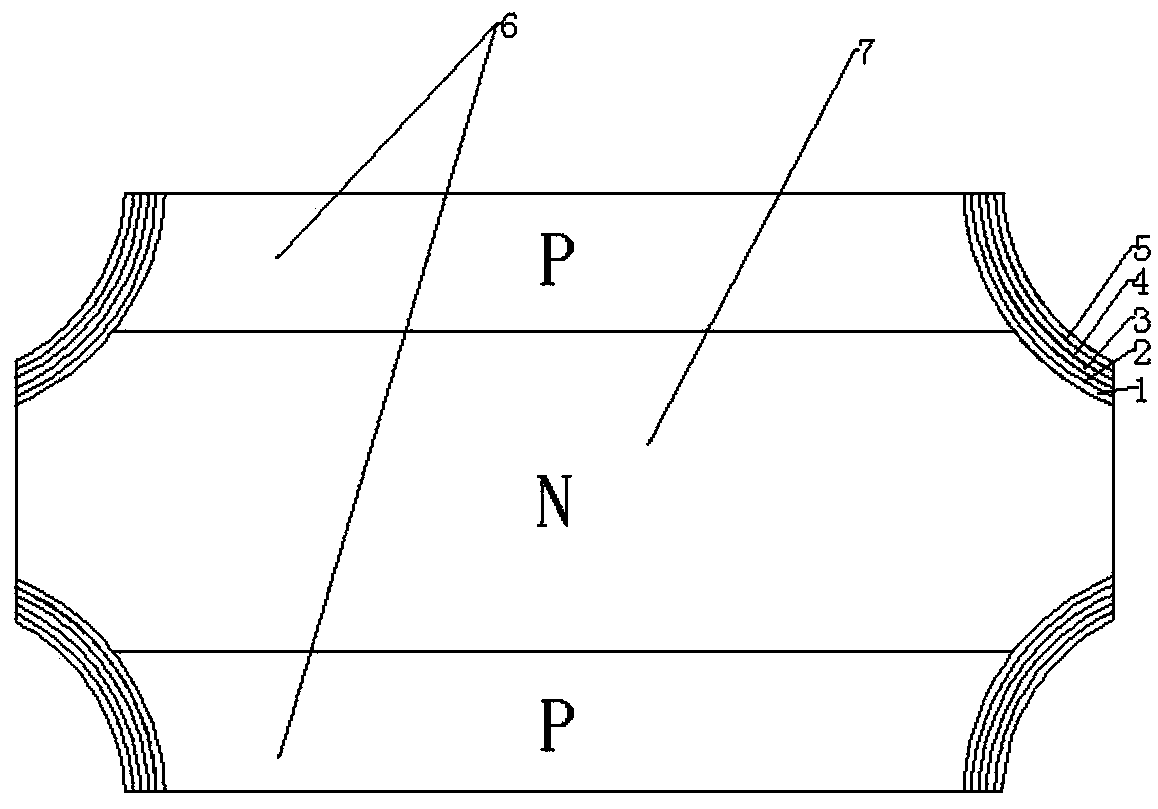

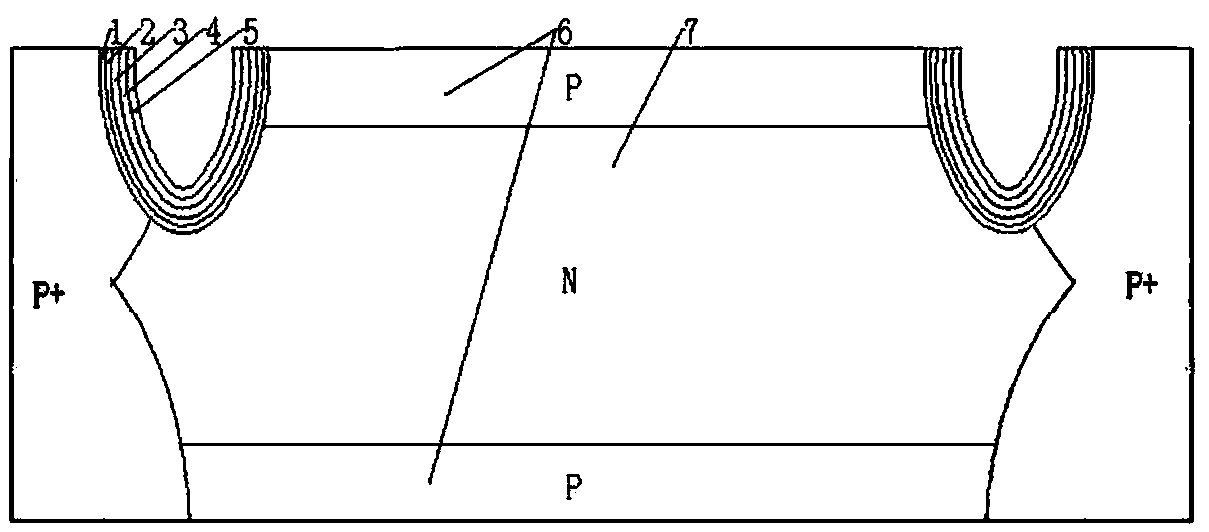

[0031] Such as figure 1 or figure 2 Shown, a kind of compound passivation film of semiconductor device of the present invention, described passivation film comprises five-layer structure, one layer is positioned at the polysilicon film layer 1 on the base, is arranged on the SIPOS film layer 2 on the polysilicon layer 1, sets The LTO film layer 3 on the SIPOS film layer 2 also includes a PSG film layer 4 disposed on the LTO film layer 3 , and an oxygen-enriched silicon dioxide film layer 5 on the PSG film layer 4 .

[0032] The above is the core of the present invention, the polysilicon layer 1 of the composite film passivation film of the semiconductor device can realize lattice adaptation, repair the damage of the silicon chip lattice in the groove, and reduce the junction surface leakage current; the SIPOS film layer 2, the shielding can The influence of moving ions and external electric field on the device can improve the breakdown voltage of the device and reduce the hi...

Embodiment 2

[0039] A process for preparing a composite passivation film for a semiconductor device. The passivation film includes a five-layer film formed by low-pressure chemical vapor deposition. The temperature of the PSG film layer is 420 °C and the pressure is 0.2 °C. Torr; the temperature for low-pressure chemical vapor deposition of the oxygen-increased silicon dioxide layer is 420°C and the pressure is 0.3t, and the temperature for high-temperature densification is 780°C and the pressure is 0.01Torr.

[0040] Specifically, the passivation film includes the following process steps:

[0041] Step 1: Deposit polysilicon by using low-pressure chemical vapor deposition at a temperature of 560°C and a pressure of 0.2Torr, SiH 4 Flow rate 50cc / min, deposition time 6min;

[0042] Step 2, deposit SIPOS at a temperature of 650°C and a pressure of 0.3Torr, SiH 4 The flow rate is 250cc / min, the N2O flow rate is 40cc / min, and the deposition time is 55min;

[0043] Step 3, depositing the LTO...

Embodiment 3

[0049] A process for preparing a composite passivation film for a semiconductor device. The passivation film includes a five-layer film formed by low-pressure chemical vapor deposition. The temperature of the PSG film layer is 450°C and the pressure is 0.4 Torr; the temperature for low-pressure chemical vapor deposition of the oxygen-enriched silicon dioxide layer is 445° C. and the pressure is 0.3 Torr, and the temperature for high-temperature densification is 820° C. and the pressure is 0.03 Torr.

[0050] Specifically, the passivation film includes the following process steps:

[0051] Step 1: Deposit polysilicon by using low-pressure chemical vapor deposition at a temperature of 580°C and a pressure of 0.4Torr, SiH 4 Flow rate 50cc / min, deposition time 10min;

[0052] Step 2, deposit SIPOS at a temperature of 670°C and a pressure of 0.3Torr, SiH 4 The flow rate is 250cc / min, the N2O flow rate is 40cc / min, and the deposition time is 60min;

[0053] Step 3, deposit the LT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com