Organosilicon vinyl acetate-acrylic emulsion and preparation method thereof and redispersible emulsion powder prepared from organosilicon vinyl acetate-acrylic emulsion

A vinegar-acrylic emulsion and silicone technology, applied in the field of emulsions, can solve the problems of poor bonding strength and water resistance, and poor bonding strength and water resistance of redispersible latex powder, so as to overcome the poor bonding strength and water resistance, improve the Water resistance and redispersibility, added protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

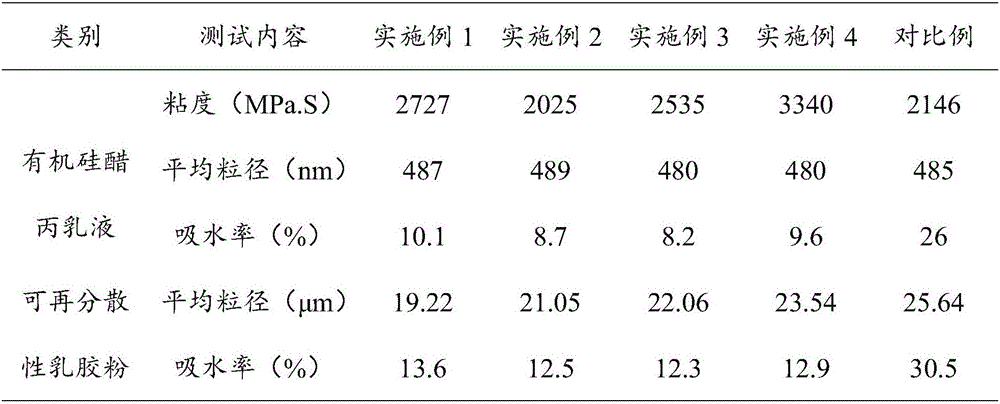

Examples

Embodiment 1

[0026] The invention provides a silicone-acrylic emulsion, which comprises: 8kg of vinyl acetate, 1.2kg of butyl acrylate, 0.5kg of functional monomer, 0.2kg of crosslinking monomer, 0.1kg of silane coupling agent, protective colloid 0.3kg, emulsifier 0.02kg, buffer 0.02kg, redox initiator 0.02kg, water 9kg. Among them, the functional monomer is isodecyl acrylate; the crosslinking monomer is diethylene glycol dimethacrylate; the silane coupling agent is vinyltriethoxysilane; the protective colloid has a degree of polymerization of 1000 and a degree of alcoholysis It is 88% polyvinyl alcohol; the emulsifier is fatty alcohol polyoxyethylene ether; the buffer is anhydrous sodium acetate; the redox initiator is benzoyl peroxide / sucrose.

[0027] The present invention also provides a kind of preparation method of organosilicon vinegar acrylic emulsion, the method comprises the following steps:

[0028] (1) Mix and stir 0.3kg of protective colloid, 4.5kg of water, and 0.02kg of emu...

Embodiment 2

[0034] The invention provides a silicone-acrylic emulsion, which comprises: 7kg of vinyl acetate, 1.6kg of butyl acrylate, 0.8kg of functional monomer, 0.4kg of crosslinking monomer, 0.2kg of silane coupling agent, protective colloid 0.6kg, emulsifier 0.1kg, buffer 0.04kg, redox initiator 0.04kg, water 10kg. Among them, the functional monomer is isotridecyl methacrylate; the crosslinking monomer is 1,3 butanediol dimethacrylate; the silane coupling agent is vinyltrimethoxysilane; the protective colloid is polymerized Polyvinyl alcohol with a degree of 500 and an alcoholysis degree of 88%; the emulsifier is a mixture of alkyl sulfate and alkylphenol polyoxyethylene ether at a mass ratio of 1:1.5; the buffer is sodium bicarbonate; redox initiator For tert-butyl hydroperoxide / carved white block.

[0035] The present invention also provides a kind of preparation method of organosilicon vinegar acrylic emulsion, the method comprises the following steps:

[0036] (1) Mix and sti...

Embodiment 3

[0042] The invention provides a silicone-acrylic emulsion, which comprises: 7kg of vinyl acetate, 3kg of butyl acrylate, 1.5kg of functional monomer, 0.1kg of crosslinking monomer, 0.02kg of silane coupling agent, and 1kg of protective colloid , emulsifier 0.5kg, buffer 0.05kg, redox initiator 0.05kg, water 12kg. Wherein, the functional monomer is octadecyl methacrylate; the crosslinking monomer is glycidyl methacrylate; the silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane; The protective colloid is polyvinyl alcohol with a polymerization degree of 500 and an alcoholysis degree of 88%; the emulsifier is a mixture of sulfosuccinate and alkylphenol polyoxyethylene ether at a mass ratio of 1:2; the buffer is sodium bicarbonate ; The redox initiator is hydrogen peroxide / tartaric acid.

[0043] The present invention also provides a kind of preparation method of organosilicon vinegar acrylic emulsion, the method comprises the following steps:

[0044] (1) 1kg of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com