Green preparation method of cationic type PVDF (Polyvinylidene Fluoride) membrane material

A technology of vinylidene fluoride and a new method, which is applied in the field of green preparation of cationic polyvinylidene fluoride membrane materials, can solve the problems of low polymerization activity and limited space for chemical modification, and achieve pure products and mild and stable polymerization conditions. control, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in further detail.

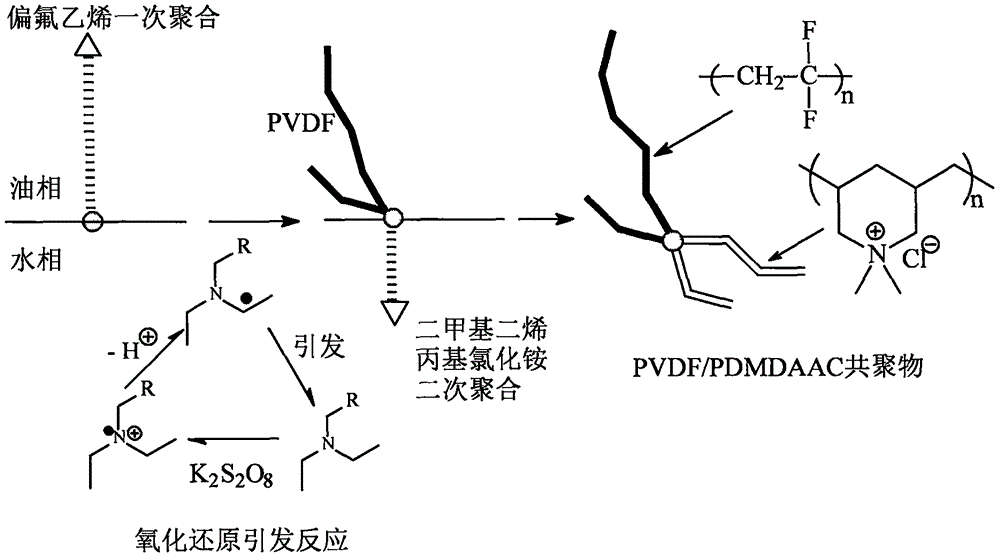

[0022] Vinylidene fluoride / dimethyl diallyl ammonium chloride copolymer is prepared according to the following steps:

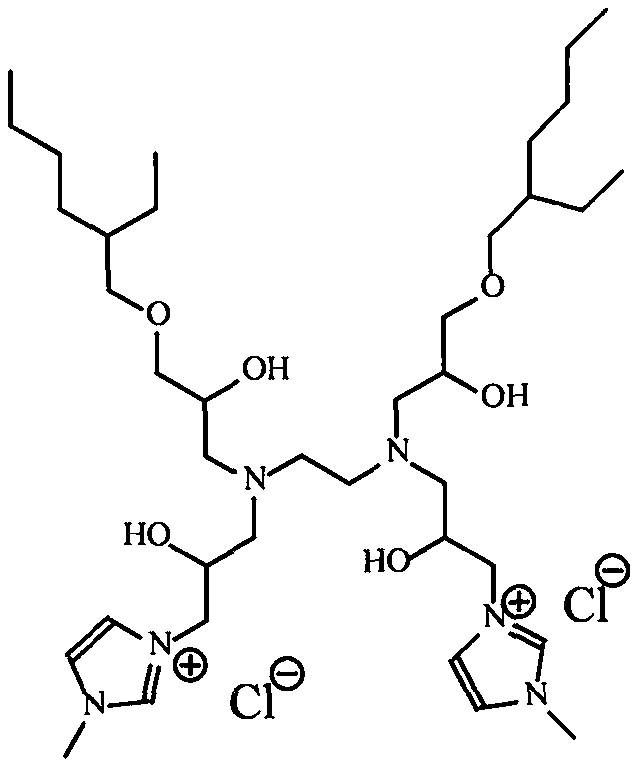

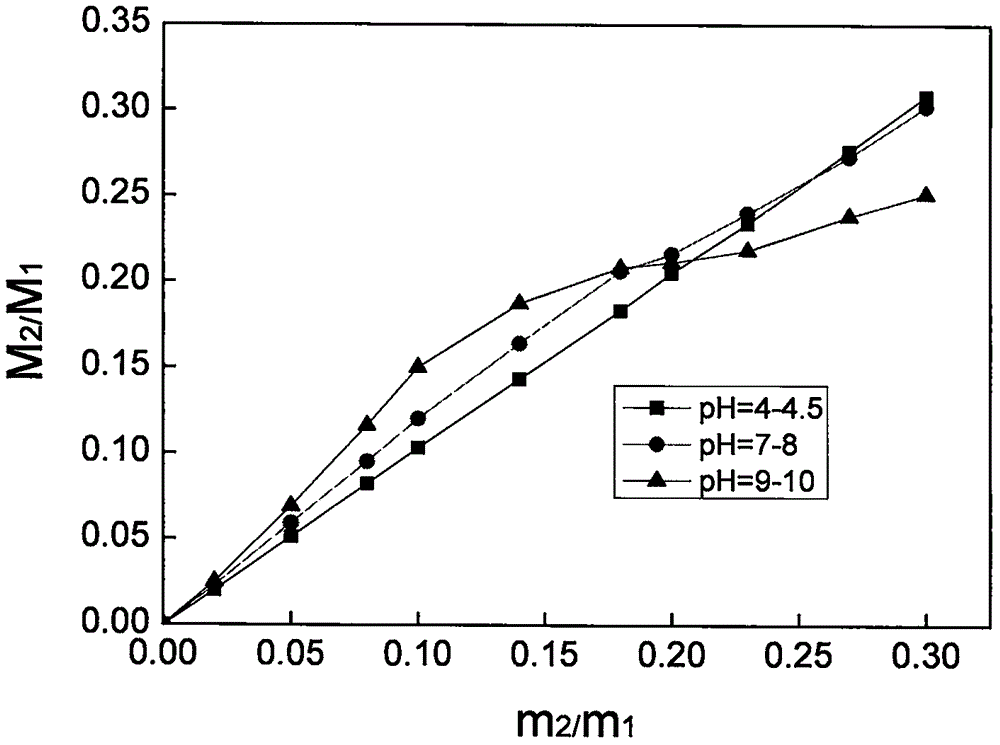

[0023] a. Dissolve 1.5g Gemini-type cationic surfactant initiator in 500mL water, the concentration is generally in the range of 2.5-3.0‰, the amount of initiator is generally 2.5-3.0% of the weight of vinylidene fluoride, by adding different amounts of acetic acid and phosphoric acid Sodium mixture to adjust the pH value of the aqueous solution (pH = 9 ~ 10; pH = 7 ~ 8; pH = 4.0 ~ 4.5), the aqueous solution is placed in a closed high-pressure reactor, and nitrogen is passed into the reactor to remove the internal air ;

[0024] b. Inject 55g of oil-soluble monomer vinylidene fluoride (boiling point at 0.1MPa is -84°C) into the reactor, maintain a pressure of 5.5MPa at room temperature, keep the monomer in a liquid state, and add potassium persulfate to satura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com